Strain Engineering Controlls Atomic Structure for Tailored Materials Properties

Definition: Strain engineering is a critical field of materials science and nanotechnology that involves the deliberate application of strain to alter the physical properties of materials. This technique manipulates the atomic structure of materials to tailor their electronic, optical, magnetic, and mechanical properties for enhanced functionality in various applications.

Principles of Strain Engineering

At the heart of strain engineering is the concept that mechanical deformation can significantly impact the electronic band structure and thus the physical properties of materials. By applying tensile or compressive strain, the atomic lattice of a material can be stretched or compressed, respectively, altering its electrical, optical, and magnetic behaviors. This alteration enables the fine-tuning of material properties beyond their natural state, offering new possibilities for technological advancements.

Techniques in Strain Engineering

Strain can be introduced to materials through various methods, including mechanical stretching, bending, compressing, or by epitaxial growth on substrates with different lattice constants. Advanced nanofabrication techniques such as lithography and etching are also used to create precise geometric patterns that induce strain in targeted areas of a material.

Benefits of Strain Engineering

- Property Enhancement: Strain engineering can significantly improve material properties such as electron mobility, optical absorption, and thermal conductivity, leading to superior device performance.

- Material Versatility: By altering the properties of materials, strain engineering expands the range of applications for which a material can be used, enhancing the functionality of electronic and photonic devices.

- Energy Efficiency: Devices engineered with strained materials often exhibit lower power consumption, contributing to more energy-efficient technologies.

- Innovation in Device Fabrication: The ability to tailor material properties through strain opens up new avenues for the design and development of advanced electronic and photonic devices.

Challenges and Considerations

- Control and Uniformity: Achieving precise control over the amount and uniformity of strain applied to materials is critical for consistent device performance but can be challenging to realize.

- Material Stability: Long-term stability of strained materials is essential for the durability of devices, requiring careful consideration of material and strain limits.

- Integration with Manufacturing Processes: Incorporating strain engineering into large-scale manufacturing processes poses challenges in terms of scalability and cost-effectiveness.

Applications of Strain Engineering

The versatility of strain engineering has led to its application in a wide range of fields:

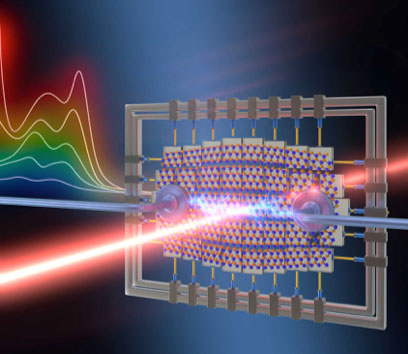

- Semiconductor Devices: Enhancing the performance of transistors, lasers, and LEDs through improved electron mobility and bandgap engineering.

- Photovoltaics: Increasing the efficiency of solar cells by optimizing the absorption properties of semiconductor materials.

- Flexible Electronics: Developing wearable electronics and flexible displays by using materials that can withstand bending and stretching.

- Quantum Computing: Tailoring the quantum properties of materials to create qubits for quantum computing applications.

Straintronics: A Frontier in Electronics

A notable application of strain engineering is in the emerging field of straintronics, where strain is used to control the electronic properties of materials for next-generation electronic devices.

By applying precise amounts of strain, researchers can manipulate the conductivity, magnetoresistance, and other electronic characteristics of materials at the nanoscale. This enables the development of highly efficient, low-power devices such as straintronic transistors, memory devices, and sensors. Straintronics showcases the potential of strain engineering to not only tailor material properties but also to create innovative solutions for the electronics industry, marking a significant step forward in the development of energy-efficient and high-performance electronic components.

Impact on Semiconductor Manufacturing and 2D Materials

In the field of semiconductor manufacturing, strain engineering stands out as a pivotal strategy for enhancing device performance. The technique's primary aim is to adjust the semiconductor's bandgap through the application of mechanical strain, thereby directly influencing its electronic properties. This manipulation allows for the optimization of charge carrier mobility, leading to semiconductors that operate more efficiently and at higher speeds. As a result, strain engineering is integral to developing advanced processors, memory devices, and a range of other semiconductor-based technologies.

Moreover, the advent of 2D materials has opened new avenues for strain engineering. These materials, including graphene, transition metal dichalcogenides (TMDCs), and black phosphorus, exhibit extraordinary electrical and optical properties that are highly sensitive to deformation. By applying strain, researchers can precisely control these properties, paving the way for groundbreaking applications in electronics, optoelectronics, and flexible devices. Strain engineering in 2D materials not only allows for the fine-tuning of their inherent characteristics but also introduces new functionalities that are not accessible through conventional material processing techniques.

The exploration of strain engineering in both semiconductor manufacturing and 2D materials underscores its critical role in pushing the boundaries of current technology. By harnessing the power of strain, scientists and engineers are able to craft materials with tailored properties, heralding a new era of electronic and photonic devices that are more powerful, efficient, and versatile than ever before.

Further Reading

Nano Energy, Straining techniques for strain engineering of 2D materials towards flexible straintronic applications

Light: Science & Applications, Strain engineering of 2D semiconductors and graphene: from strain fields to band-structure tuning and photonic applications