| Mar 21, 2019 | |

Miniature Piezo Components for Medical Device Manufacturing |

|

| (Nanowerk News) In 1880, brothers and colleagues Jacques and Pierre Curie discovered that putting pressure on certain materials created electricity. Taken from the Greek word for “squeeze” (piezein), piezoelectricity was born. Commonly known as the “piezo effect”, it also occurs when an electrical field is applied and changes the dimensions of materials. More than a hundred years later, PI Ceramic (a division of PI Physik Instrumente) is a leader in the field of piezo ceramic components, including its newest line of mini transducers. | |

|

|

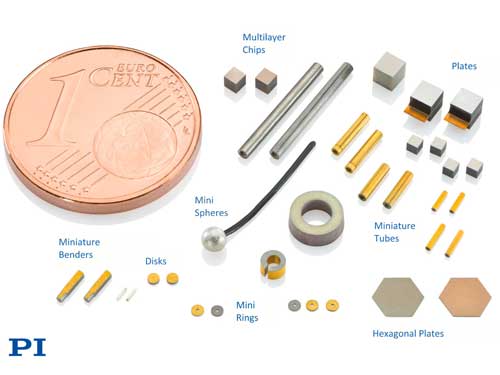

| Examples of Mini Piezo Ceramic Component Shapes (click on image to enlarge) | |

Applications |

|

| One of the latest applications of miniature piezo tube transducers can be found in scanning fiber / scanning catheter endoscopes (SFE). These miniature endoscopes provide laser-based high resolution video to enable minimally invasive procedures. Miniaturized piezo plates are used to drive pumps for micro-dosing and nano-dosing of drugs. Ultrasonic piezo transducers can be used for bubble detection in dialysis or blood transfusion applications and for atomization of medication (aerosol generation) to name a few. | |

High Dynamics in a <1mm Package |

|

| Piezo ceramic actuators and transducers achieve high dynamics with frequencies up to Millions of Hertz and excellent reliability. Various shapes and very small dimensions are possible to create precision motion based on crystalline solid-state effects. For example, the new ultra-small piezo tube transducers come in two standard sizes: 0.2/0.5mm ID/OD (inner/outer diameter) with 4mm length, and 0.9/1.5mm ID/OD with 15mm length. | |

Custom Geometries, Materials, and Electrodes |

|

| Custom geometries (length, diameter) and custom materials are available, in addition to the large variety of standard piezo tubes and tubular stack transducers offered by PI. Customers can choose from electrodes applied in thick-film and thin film technology. Other options include multi-segmented electrodes for multi-axis scanning operation and modified response behavior as well as wrap-around contacts for easy integration into a mechanical assembly. Lead-free is also available. | |

| More Information on Miniaturized Piezo Transducers | |

| Application Articles on Piezo Transducers | |

Standard and Custom |

|

| PI has in-house engineered solutions with over 4 decades of experience working with customers to provide products that meet application demands, and can quickly modify existing product designs or provide a fully customized OEM part to fit the exact requirements of the application. | |

About PI |

|

| PI is a leading manufacturer of air bearing stages, piezoelectric solutions, precision motion control equipment, and hexapod parallel-kinematics for semiconductor applications, photonics, bio-nano-technology and medical engineering. PI has been developing and manufacturing standard & custom precision products with piezoceramic and electromagnetic drives for 4 decades. The company has been ISO 9001 certified since 1994 and provides innovative, high-quality solutions for OEM and research. The PI group employs more than 1,000 people worldwide in 15 subsidiaries and R&D / engineering centers on 3 continents. |

| Source: PI (press release) |

Subscribe to a free copy of one of our daily

Nanowerk Newsletter Email Digests

with a compilation of all of the day's news.

Nanowerk Newsletter Email Digests

with a compilation of all of the day's news.