| Dec 17, 2019 | |

Gantry Motion System for Inspection, Assembly, and 3D Printing |

|

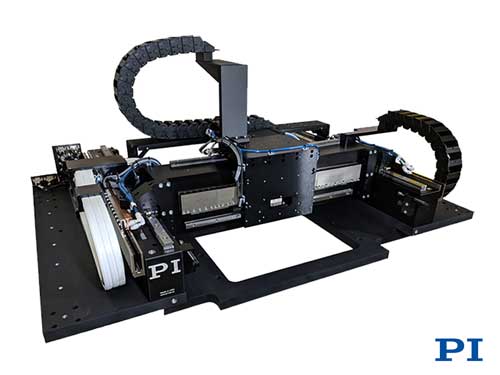

| (Nanowerk News) PI’s new compact XY / XYZ gantry motion system provides overhead motion for industrial automation applications in assembly, pick-and-place, alignment, inspection, and custom 3D printer design. The A-351 compact gantry is designed and manufactured in the USA by PI’s air bearing & precision motion division in Hopkinton, MA. | |

| The A-351 gantry motion system is related to the A-341 hybrid air bearing gantry. Driven by linear motors and guided by precision mechanical linear bearings, the system provides high speed and accuracy, at a lower price compared to its air bearings-based brother. | |

| Advanced absolute linear encoders increase accuracy and reduce start-up time by rendering homing procedures unnecessary. The integrated ironless linear motors eliminate cogging, providing smoother motion without vibration and better velocity control. | |

| The highest motion performance and easy integration with factory automation systems is guaranteed by an ACS-based motion controller with EtherCat connectivity. | |

|

|

| XY / XYZ gantry systems, A-351. | |

Optional Z-Axis Stage / Customizations |

|

| For applications requiring a motorized vertical axis, several Z-stage options are available, with either screw-driven platforms or linear motors and pneumatic counterbalance. Other customizations, such as mounting platforms for vision systems, dispensers etc, are also offered. | |

Features of the gantry motion system include: |

|

|

|

|

Industry-Leading Motion Controllers |

|

| The A-351 overhead gantry motion system is available with a range of industry-leading ACS motion controllers / drives that offer superior servo performance, advanced control algorithms to improve dynamic performance and error compensation specifically for gantries, and a wide suite of software development tools. | |

| A-351 Details | |

| In this video: Automation Platforms and Gantries for Precision laser machining. Laser cutting, marking, micro-machining, or micro-drilling – requires highly accurate motion equipment, such as gantry systems or motorized linear and rotary stages, galvo scanners, and advanced motion controllers with high speed. | |

Standard and Custom |

|

| PI has in-house engineered solutions with over 4 decades of experience working with customers to provide products that meet application demands, and can quickly modify existing product designs or provide a fully customized OEM part to fit the exact requirements of the application. | |

About PI |

|

| PI is a leading manufacturer of air bearing stages, piezoelectric solutions, precision motion control equipment, and hexapod parallel-kinematics for semiconductor applications, photonics, bio-nano-technology and medical engineering. PI has been developing and manufacturing standard & custom precision products with piezoceramic and electromagnetic drives for 4 decades. The company has been ISO 9001 certified since 1994 and provides innovative, high-quality solutions for OEM and research. The PI group employs more than 1,300 people worldwide in 15 subsidiaries and R&D / engineering centers on 3 continents. |

| Source: PI (press release) |

Subscribe to a free copy of one of our daily

Nanowerk Newsletter Email Digests

with a compilation of all of the day's news.

Nanowerk Newsletter Email Digests

with a compilation of all of the day's news.