| Jul 17, 2019 | |

High magnetic field of 10T during activated carbon production improves micropore capacity by 35%(Nanowerk News) Carbon materials such as graphene, activated carbon, carbon nanotubes and graphite are in high demand. Demands are thought to continue to increase because carbon materials have many beneficial uses and new applications are being discovered. They are essential to air and water purification, electrodes in metal refining, manufacturing pencils and lubricants. |

|

| The carbon source quality (coal tar pitch), temperature, atmosphere, and preparation methods have great impact on the properties of carbon materials. This is because the structure of carbon materials effect their properties, and the structure can be manipulated in production. | |

| Advancing new control parameters during production will lead to the refinement of the functionality of carbon materials. | |

| All materials interact somewhat with magnetic fields whether or not they are magnetic. There have been many other research explorations into methods of orienting graphene and nanotubes in a magnetic field. | |

| However, there have been no reports of experiments using a High Magnetic Field (HMF) in the preparation process of carbon materials to manipulate the structure. This current research was made possible by the superconducting magnets that can create magnetic fields of 10 Teslas and beyond. | |

|

|

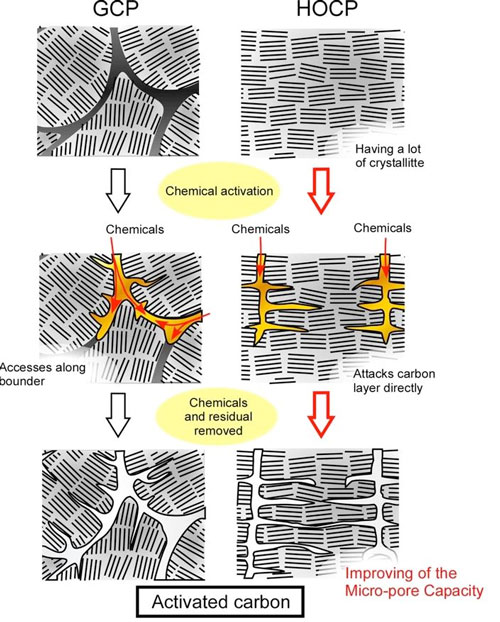

| Schematic drawing of the effect of an applied magnetic field on the formation of activated carbon. (© Springer Nature) | |

| The research team lead by Atom Hamasaki of the Institute of Science at Shinshu University set out to create more efficient forms of activated carbon by utilizing the superconducting magnets to coax activated carbon precursor of carbonized coal tar pitch during the mesophase (liquid crystal) to form crystallites (similar process to making graphite), thus increasing the volume of pores in the activated carbon by 35% (Scientific Reports, "Improving the Micropore Capacity of Activated Carbon by Preparation under a High Magnetic Field of 10 T"). | |

| The HMF encourages crystallites to form, and when there are more crystallites, more crevasses are created where chemicals can come into contact with the activated carbon. Many other materials that have negative magnetic susceptibility may also be manufactured using this effective procedure with HMF to control for better properties. |

| Source: Shinshu University | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |