| Dec 12, 2019 | |

Slippery when wet: how does lubrication work?(Nanowerk News) In a recent paper in Sciences Advances ("Fluorescence microscopy visualization of the roughness-induced transition between lubrication regimes"), researchers from the University of Amsterdam present new experimental insight into how lubrication works. They have developed a new method using fluorescent molecules to directly observe nanometric lubrication films with a sensitivity of a single molecular layer. |

|

| Their quantitative description of the relation between topography, contact pressure and lubrication provides a deeper understanding of lubrication. | |

|

|

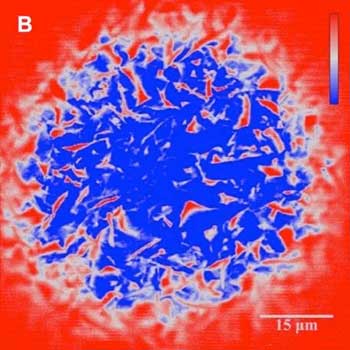

| Fluorescence intensity image of the contact between a polystyrene sphere and the glass substrate. The scale bar indicates fluorescence intensity gradient from the lowest (blue) to the highest (red) values. Blue regions correspond to the load-bearing area. (© Science Advances) | |

| Friction and wear are responsible for a large fraction of the world energy consumption and therefore contribute enormously to greenhouse emissions. Literally every moving object dissipates energy through friction. Examples with large economic impact can be found in the transport and energy sectors: think of an internal combustion engine or a gas turbine. | |

| To reduce friction and wear, sliding and rolling contacts are typically lubricated. For instance, in an internal combustion engine, the engine oil acts as a lubricant, preventing solid-on-solid contact between the piston ring and the cylinder wall, reducing friction and wear at this interface. | |

Thinner lubricant layers |

|

| In general, there is a trend towards thinner lubrication layers because of increasingly strict requirements on material use, demands for higher efficiency, and a need for “greener” lubricants. Under these conditions, the successful lubrication and long term safe operation is increasingly sensitive to the topography of the lubricated surfaces. Although many studies in engineering and physics have led to a high level of understanding of lubrication, at the small scale where layers break up significant questions are as of yet unanswered. | |

| A major missing link is a detailed experimental insight into the influence of the specifics of the surface topography on the transition between different regimes of lubrication. In particular, there is much discussion on the phenomena occurring when the thickness of the lubrication film spans only a few molecules. | |

Linking surface topography with lubrication phenomena |

|

| Fundamental studies, for instance on friction forces using Atomic Force Microscopy, have provided some insight. However, since these concern the microscopic scale, their relevance to macroscopic phenomena is limited. On the other hand, studying the interplay between lubrication and surface topography at a macroscopic scale is very challenging since the lubrication layer is buried between two solids and is therefore difficult to access experimentally. | |

| In their paper in Science Advances, the researchers now present the results of a new approach that does enable fundamental research on a macroscopic level with very high resolution, linking surface topography with lubrication phenomena. | |

| The research was performed at the University of Amsterdam's Van 't Hoff Institute for Molecular Sciences (HIMS) and Institute of Physics (IOP). Researchers from the Dutch Advanced Research Center for Nanolithography (ARCNL), University of Twente (Enschede, the Netherlands) and the Université Paris-Saclay (Paris, France) contributed to the study. Fluorescent molecular probes | |

|

|

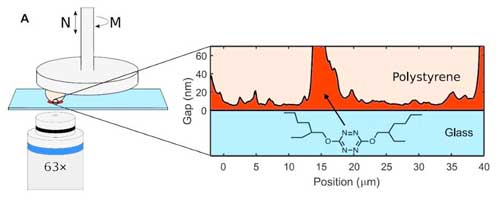

| Experimental setup. A rheometer measuring head is mounted on top of an inverted confocal microscope. A float glass coverslip is used as the transparent substrate. A sphere, glued to the rheometer tool, is lowered into contact with the substrate, and the contact is immersed in a fluorescent liquid. By lowering and rotating the rheometer tool, the normal force (FN) and frictional force can be imposed and measured, respectively. Fluorescence is excited and detected through the transparent substrate using the microscope. In the inset, the molecular structure of the fluorescent liquid 3,6-bis((2-ethylhexyl)oxy)-1,2,4,5-tetrazine is shown. (© Science Advances) (click on image to enlarge) | |

| At the ARCNL Contact Dynamics group of Dr Bart Weber, the focus is on fundamental aspects of friction and wear with relevance to positioning challenges in nanolithography. For the research now published in Science Advances, the group joined forces with Prof. Fred Brouwer and Prof. Daniel Bonn of the University of Amsterdam, where first author Dr Dina Petrova obtained her PhD earlier this year. | |

| The researchers performed friction experiments with a very special lubricant invented by the French co-authors Dr Clémence Allain and Prof. Pierre Audebert: a pure liquid that consists of fluorescent molecules. By lubricating transparent, glass-on-glass contacts with this liquid, the researchers were able to directly visualize the lubricating film of only a few molecules thick. After excitation of the fluorescent liquid through the glass, they measured the local fluorescence intensity that is proportional to the number of molecules present at the interface. | |

| The experimental results were compared to theoretical predictions co-developed by Prof. Kees Venner from the University of Twente. | |

Glass transition |

|

| By quantitatively analyzing the relation between the surface topography, the lubricant film thickness and the friction, the researchers show that confinement of the lubricant between the sliding surfaces leads to a glass transition, meaning that the fluid becomes highly viscous and thus resists being squeezed out of the interface. | |

| However, the increased viscosity is not always sufficient to prevent squeeze-out. At the interface, there is a competition between the pressure and the viscosity of the lubricant. The interfacial pressure depends on the load-bearing area that is controlled by the surface topography: the rougher the two surfaces, the smaller the (potential) contact area. | |

| Thanks to their experimental set-up, the researchers were able to quantitatively describe this relation between topography, contact pressure and lubrication. The results thus provide a deeper understanding of how lubrication works and can help in predicting the friction behaviour in a multitude of lubricated systems with large societal impact. |

| Source: Universiteit van Amsterdam | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |