| Jan 15, 2020 | |

Imprinted structural color patterns(Nanowerk News) Structural colors appear because the imprinted pattern on a surface changes the wavelengths of light. Chinese scientists have introduced an azopolymer that allows the imprinting of nanopatterns in a novel room-temperature lithographic process. |

|

| A key aspect of the technique is the light-induced phase change of a novel azopolymer, explains the study published in the journal Angewandte Chemie ("Athermal and Soft Multi-Nanopatterning of Azopolymers: Phototunable Mechanical Properties"). The process relies solely on light regulation and allows nanoimprinting even on flexible substrates. | |

|

|

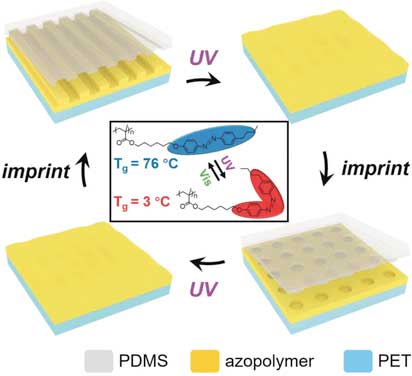

| Azopolymer material allows light-assisted imprinting of nanostructures for structurally colored surfaces. (© Wiley) | |

| Delicately structured surfaces are present in many relevant areas, including anticounterfeiting of banknotes and chip manufacturing. In the electronics industry, surface patterns, such as printed circuits, are created by photolithographic processes. | |

| Photolithography means that a photoresist, a polymeric material sensitive to ultraviolet (UV) light, is irradiated through a mask. The weakened areas are washed away, and the structures are finished by etching, imprinting, and other processes. To prepare the photoresist for UV-light irradiation, heating and cooling are important steps, which cause changes in the material behavior. | |

| Unfortunately, materials tend to shrink upon cooling, which poses problems when nanosized patterns are desired. Therefore, Haifeng Yu and his colleagues from Peking University have developed a nanolithography process that works entirely at room temperature. | |

| Key to the method is a novel photoresist that changes its mechanical behavior solely by light irradiation. A heating step is no longer necessary. The new photoresist contains a chemical component called azobenzene, which switches from a straight “trans” into a bent “cis” form, and vice versa, when irradiated with light. This azobenzene, which is attached to the polymer backbone, causes the mechanochemical changes of the resulting azopolymer. | |

| For pattern fabrication, the authors first liquefied the azopolymer layer coated on a flexible plastic surface by shining UV light on it. Then they pressed a transparent nanopatterned silicone sheet on the liquefied areas and irradiated the layers with visible light. This light induced hardening of the azopolymer, which adopted the template nanopattern. Then the scientists applied a photomask and irradiated the layers with UV light to re-liquefy the uncovered areas. | |

| For the final imprint, they pressed another nanopatterned sheet on the azopolymer structure and hardened the layers with visible light to obtain the finished nanopatterned coating layer. This technique is called “athermal nanoimprint lithography”. | |

| The nanopatterned surface appeared in multiple structural colors. Tiny letters or ornamental drawings changed their colors depending on the angle they were viewed at. According to the authors, the technique is not limited to structural colors. “It is adaptable to many other substrates like silicon wafers and other light-active materials,” they say. The researchers envision applications in nanofabrication areas where heat-independent imprinting processes are required and phototunable materials have advantages. |

| Source: Wiley | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |