| Jan 18, 2022 |

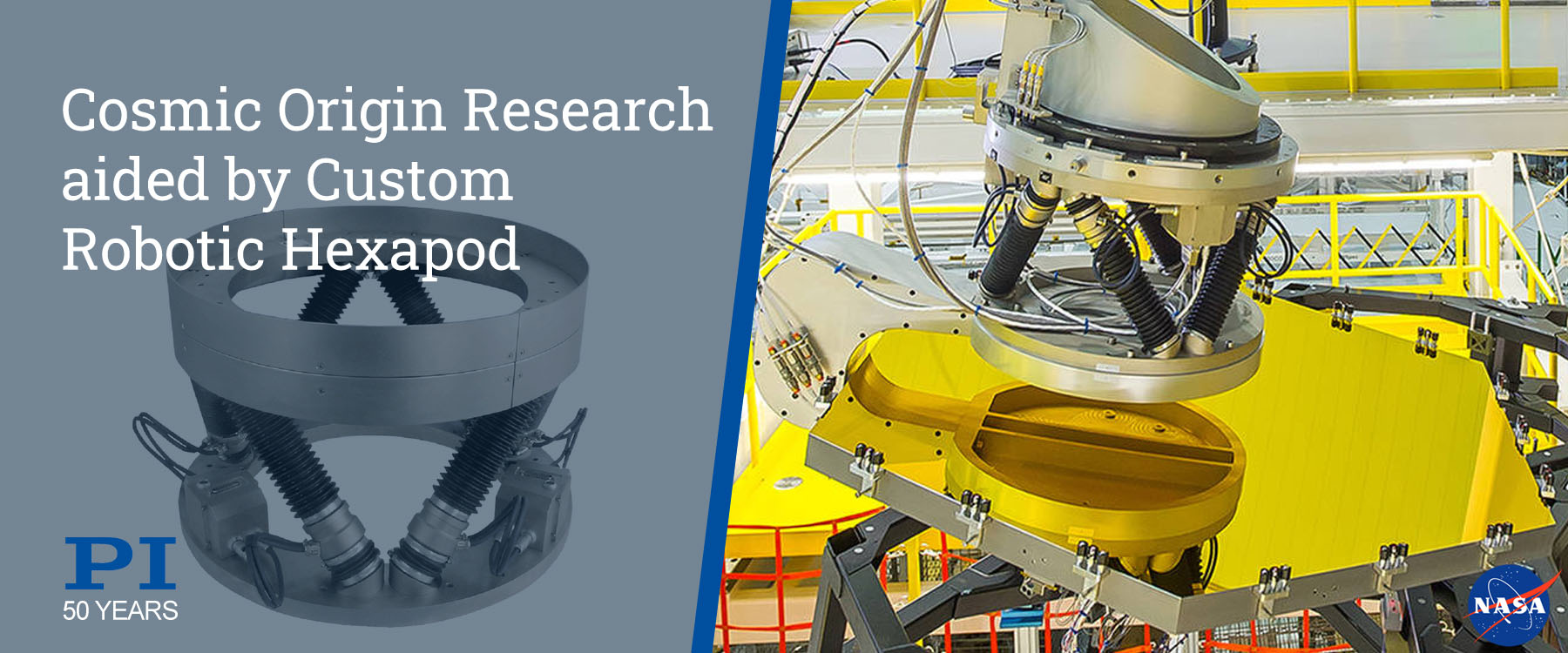

James Webb Space Telescope mirrors aligned by 6-axis nanopositioning system

(Nanowerk News) Orbiting approximately one million miles from Earth, the James Webb Space Telescope (JWST) is the largest telescope ever launched into space – in its unfolded operational configuration it is nearly the size of a tennis court. Webb’s lightweight deployable primary mirror is segmented into 18 hexagonal pieces on a hinged surface over 21 feet in diameter (6.5 meters).

|

|

| James Webb Space Telescope Mirrors Aligned by 6-Axis Precision Hexapod Stage.

|

|

During the assembly of the 18 segments that must work as one single mirror once unfolded in space, NASA engineers make use of a robotic arm (Primary Mirror Alignment and Integration Fixture) precisely controlled in 6 degrees of freedom by a custom hexapod (Stewart Platform) from PI. Gold-coated beryllium was chosen for the segments, for its high stiffness, low weight, and properties to withstand the extremely low temperatures in outer space. Each segment also has a thin gold coating to reflect infrared light.

|

|

Positioned at the end of the robotic arm, the custom hexapod has a 200kg load capacity and sub-micrometer resolution, to precisely position the JWST mirror segments during assembly. Hexapods with their programmable center of rotation (pivot point) are the gold standard, when it comes to precise multi-axis alignment tasks, from nanometer sized structures in silicon photonics / fiber optics to big mirrors and reflectors in astronomy.

|

|

Based on 4 decades of experience, PI hexapods are available in many different sizes and configurations. They are supported by a host of software tools, alignment routines, and accessories. The great flexibility allows the hexapod user to adapt their 6-axis motion system to any alignment application quickly without retooling.

|

|

Previously, NASA/JPL relied on PI’s high performance multilayer piezo ceramic actuators used on the Mars rover for their extreme reliability and lifetime beyond 100 billion cycles.

|

|

PI’s hexapod controllers and hexapod software are based on decades of experience with parallel kinematic motion systems. PI’s free hexapod software simulates the limits of workspace and load capacity, thereby ensuring the hexapod you choose will handle the loads, forces, and torques in your application.

|

|

For a better understanding of Hexapod capabilities, see a collection of Applications Articles.

|

|

PI’s in-house engineered solutions have enabled customers around the world to increase their productivity and technological advantage for 5 decades. With a large basis of proven motion technologies and methodologies, PI is in the position to quickly modify existing designs or provide a fully customized OEM solution to fit the exact requirements of your application from sensors and piezo transducers to microscope nano-focus units, fast photonics alignment systems to multi-axis automation sub-systems.

|