| Jan 26, 2024 |

A next-generation semiconductor memory that operates in extreme environments

(Nanowerk News) Daegu Gyeongbuk Institute of Science and Technology (DGIST) revealed a breakthrough by Professor Hyuk-jun Kwon's team from the Department of Electronic Engineering and Computer Science. The team, including Ph.D. scholar Bong-ho Jang as the lead author, has innovated a new manufacturing process for high-quality oxide films. This process facilitates efficient patterning at lower temperatures and has successfully been used to create non-volatile resistive random access memory (RRAM).

|

|

This advancement, reported in Journal of Materials Science & Technology ("Stable switching behavior of low-temperature ZrO2 RRAM devices realized by combustion synthesis-assisted photopatterning"), is anticipated to enhance next-generation computing systems, addressing the limitations of current manufacturing methods and producing memories with superior durability.

|

|

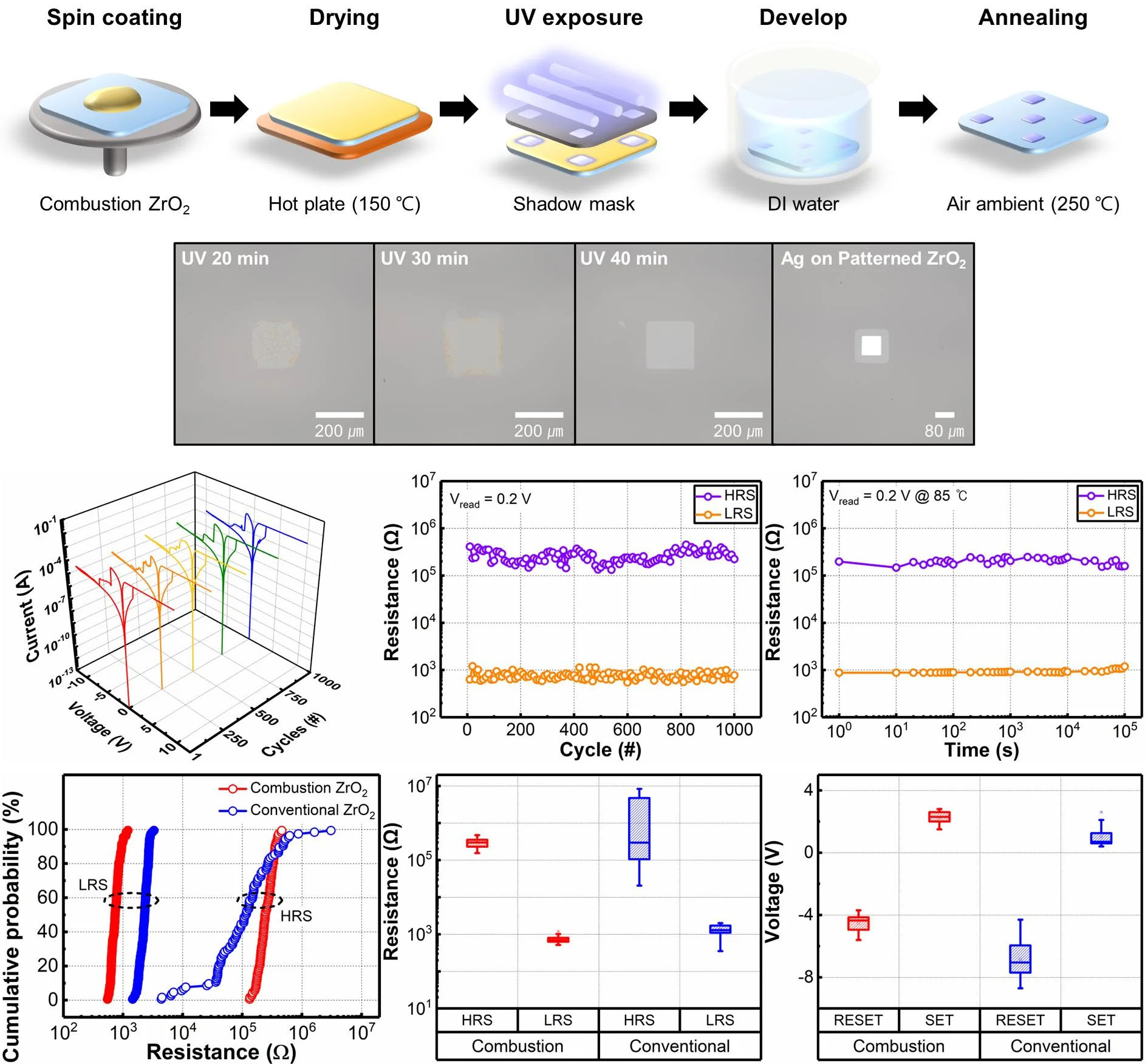

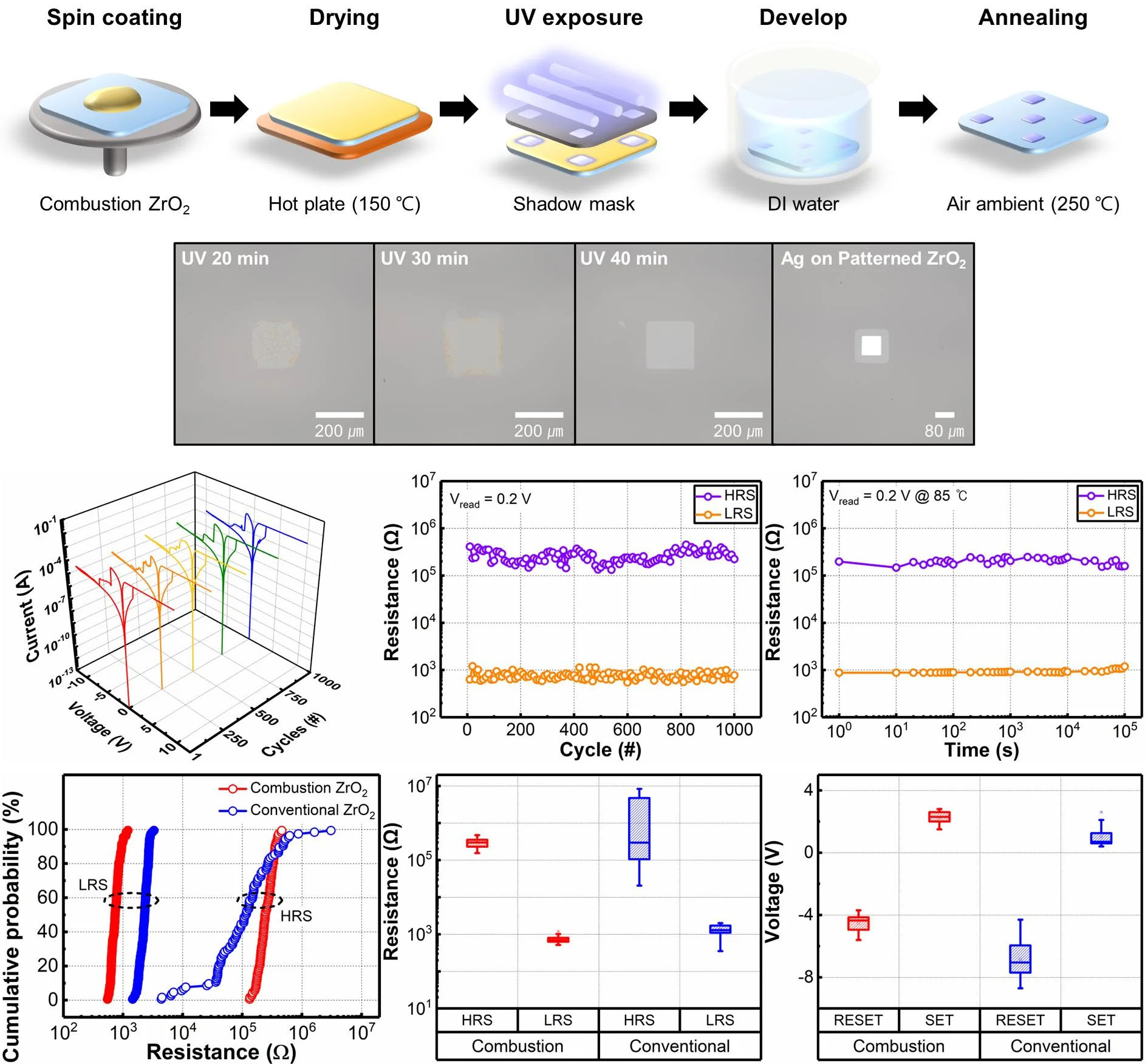

| The new manufacturing technology that enables the production of high-quality oxide films and effective patterning at low temperatures and manufactured non-volatile resistive random access memory. (Image: DGIST) (click on image to enlarge)

|

|

In the context of rapidly evolving data-centric computing systems such as artificial intelligence, big data, and Internet of Things (IoT) devices, there is a growing need for next-generation non-volatile memory. This memory type is sought after for its high durability, faster operation, and energy efficiency. RRAM, which alters memory data via electrical current, is at the forefront of this demand.

|

|

The team focused on "solution process technology," a promising method for developing RRAM, known for its cost-effective large-scale manufacturing. However, this technology traditionally operates at high temperatures and faces challenges in achieving uniform patterning.

|

|

To surmount these issues, Professor Kwon's team integrated "combustion synthesis technology" with the solution process. Combustion synthesis uses exothermic reactions for material synthesis, leveraging the heat generated during combustion. This approach effectively circumvents the need for external high-temperature conditions. Utilizing this method, the team successfully produced high-quality zirconium oxide (ZrO2) films and achieved photopatterning via photochemical reactions with ultraviolet light at lower temperatures.

|

|

The research further led to the production of a resistive random access memory using this novel technology. The resulting RRAM exhibits remarkable durability, enduring over 1,000 cycles and maintaining data retention for upwards of 100,000 seconds even in high-temperature conditions.

|

|

This study isn't Professor Kwon's first foray into low-temperature technologies. His previous work involved applying combustion synthesis to produce SnO2 thin-film transistors. The current research extends the potential of this technology, moving beyond the confines of existing solution process methods to develop an innovative type of RRAM.

|

|

Professor Kwon, from the Electrical Engineering and Computer Science Department, expressed his enthusiasm about the results. He highlighted the significant enhancement over existing solution process technologies and anticipated the impact on the development of intensive next-generation computing systems and the mass production of electronic devices based on solution processes.

|