| Posted: Sep 20, 2017 | |

Hybrid 3D-printing of soft electronics(Nanowerk News) Researchers have demonstrated a new hybrid method for manufacturing high-performance soft electronics that combines direct ink writing with automated pick-and-place of surface mount electrical components. |

|

| As the researchers report in Advanced Materials ("Hybrid 3D Printing of Soft Electronics"), by developing novel insulating and conductive inks, they fabricated and characterized functional strain and pressure sensors. | |

|

|

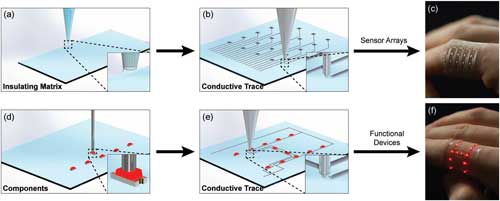

| Figure 1: Hybrid 3D printing platform for soft electronics. Schematic images of a) direct ink writing of an TPU matrix for the device body and b) conductive AgTPU traces for the sensing elements. c) Image of representative example of soft sensor array. Schematic images of d) pick-and-place (P+P) of components using vacuum nozzle onto target positions and e) direct writing of conductive AgTPU traces to interconnect the surface mounted LEDs placed in the form of a soft, stretchable “H” LED array. f) Image of a functional LED array wrapped around a human finger. (© Wiley-VCH Verlag) (click on image to enlarge) | |

| This hybrid method – which combines direct ink writing (DIW) with automated pick-and-place of surface mount electronic components within a single manufacturing platform – enables surface mount electrical components of arbitrary shapes and sizes to be readily integrated onto printed soft wearable circuits. | |

| Both insulating matrix (Figure 1a) and conductive electrode inks (Figure 1b) can be patterned in specific layouts, including soft sensing arrays (Figure 1c). Passive and active electrical components are then integrated to fabricate soft circuits by applying a modest vacuum through an empty nozzle to pick up individual components, place them onto the substrate, and then release the vacuum to deposit them in the desired location (Figure 1d). Finally, conductive traces are printed to create electrical interconnects between the P+P components (Figure 1e). | |

| "Importantly, the broad set of printable materials (e.g., ceramics, polymers, metals) and devices (e.g., antennas, batteries, waveguides) previously developed for direct ink writing offers an unique opportunity to expand the functionality 3D printed structures via this hybrid manufacturing platform," the authors conclude their report. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |