| Jul 26, 2019 |

Five 3D printing myths

|

|

(Nanowerk News) The first conviction for 3D printing a firearm was recently reported in London, not long after 3D printed masks were used to trick face recognition. Should we be afraid?

|

|

3D printing refers to a range of digital fabrication processes that build objects directly from computer models, without expensive tooling, in layers of material. Although 3D printing processes vary widely, including melting metal powder with lasers or hardening liquid plastic “ink” with ultraviolet light, most people tend to think of 3D printing desktop machines that melt spools of plastic. Since these are often built or designed by enthusiasts, they are very affordable, with some models costing under £200.

|

|

We research the realities of 3D printer usage by businesses (Technovation, "Effective use of 3D printing in the innovation process") and consumers – and so can dispel some of the most common fears around 3D printing.

|

|

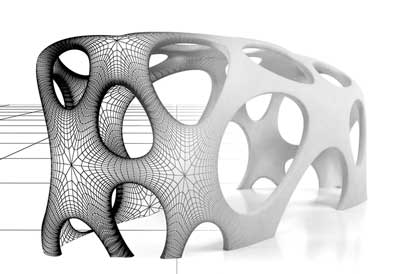

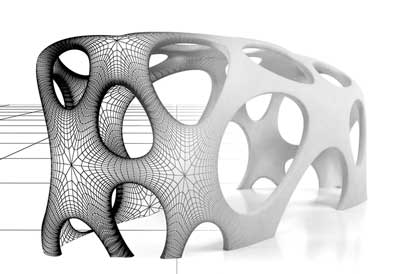

| Complex shapes that cannot be traditionally manufactured may be 3D printed. (Image: 4Delta, Author provided)

|

1. Everyone will print firearms

|

|

Designs for a “gun” that could be produced on a desktop 3D printer were first shared on the internet around 2013. While this may have been a powerful political statement, a single conviction and no reported injuries in six years suggests the threat is limited. Indeed, most experts believe 3D printed guns may be more dangerous to their users than anyone else. As one 3D printing user we interviewed said: "I’m never going to fire a 3D printed gun. With the amount of prints that go wrong, you would have to be a much braver man than I am."

|

|

While it may be possible to print something that looks like a gun, it is likely to need metal components. And ammunition. Not everything can – or should – be 3D printed.

|

2. It will destroy the environment

|

|

Some people worry that making it easy to produce plastic objects will lead to environmental problems due to the ease of printing new products.

|

|

The counter argument is that printing massively reduces waste, compared to traditional “subtractive” manufacturing (cutting, drilling etc). Also, materials may be biodegradable. For example, plant-based materials can be used to turn food waste into filament for 3D printers. 3D printing offers potential ways of using recycled plastics. And projects such as restoring marine habitats by 3D printing coral reef show how environmental sustainability can be supported by 3D printing.

|

3. It will steal our jobs

|

|

For years, 3D printing has either been described as disruptive or revolutionary. As with any technology in history, these terms have led to fears about job losses.

|

|

For example, the ability to produce complex shapes in a single part reduces business for suppliers who currently make components. On the other hand, access to low cost, local production helps turn bright ideas into business and career opportunities. Providing 3D design and printing skills is helping vulnerable people design and make jewellery rather than fall victim to exploitation. And 3D printing has allowed entrepreneurs to create low cost monitoring devices enabling coffee growers to improve their livelihood.

|

|

3D printing is a good way to increase engagement with science and engineering in schools. And in our research, we also met older people seeking to update their skills by learning 3D printing. For example, one was occupying his time in retirement making gifts for family, fixing things for for neighbours, and even teaching others to print.

|

|

Another, who previously worked in creative industries, saw 3D printing and design as way to start a business, be creative again, and get away from an unsatisfying job. Others used 3D printers to create inventions. In short, it helps make entrepreneurial dreams achievable.

|

4. Everyone will print fake products

|

|

For several years now, it has been possible for companies to make spare parts, or even new products using 3D printing – including hearing aids, sports shoes and dental crowns. So why do we not 3D print everything?

|

|

Partly because it costs much more than mass production, but also because companies fear someone will steal their designs or produce fake versions. Just as the music industry took years to stop fighting Napster and embrace digital sales, manufacturers will take time to get used to the idea that their intellectual property can be shared online. In the meantime, willingness to share is what defines the communities of 3D printing users that meet in makerspaces and online, to explore ideas, learn new skills, start businesses or just make friends.

|

|

One solution to the issue of accessible designs might be to use blockchain to keep track of 3D printed products. But at the same time companies must choose whether customers who want to create, download and print designs should be treated as collaborators or competitors.

|

|

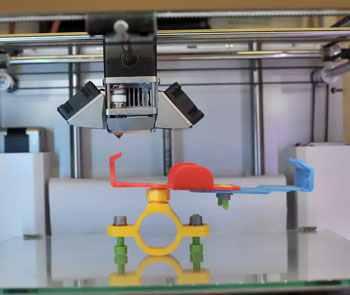

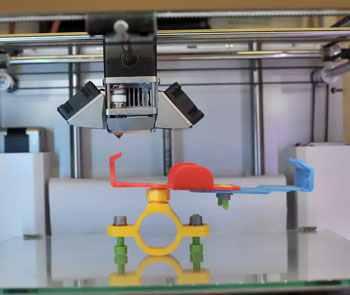

| A custom designed phone holder for a bicycle, assembled from 3D printed components. (Image: 4Delta, Author provided)

|

5. It’s too expensive

|

|

Our research has meant that we’re often explaining how 3D printing works to members of the public. As they watch the printer in action, their initial concerns about guns are often quickly replaced with questions about materials and designs. Then comes the fear that this is either too expensive, too difficult, or both, for individuals to try out themselves.

|

|

For those reluctant to splash out on their own machine, many public libraries now provide access – and most have computers that can be used to create the designs, using drawing tools that can be downloaded for free. Or if you don’t fancy creating your own designs, it is possible to download and “remix” a variety of objects from replacement parts for household repairs to aids for arthritis patients. You can even ask someone to print the designs for you.

|

|

3D printing still requires some effort – to prepare designs, to set up the printer, and to fix the inevitable mistakes. But the good news is there is a growing community of people online and in various makerspaces who are happy to help you.

|