| May 08, 2013 |

Simulations show how to avoid imperfections in the next generation of high-density data storage

|

|

(Nanowerk News) The rise of the internet and the move from paper to digital information has driven a need for large-volume electronic data storage. Maria Yu Lin and her co-workers at the A*STAR Data Storage Institute, Singapore, have now established some important design principles to consider when developing bit patterned media recording (BPMR) — a potential high-density magnetic recording system of the future ("Modeling for write synchronization in bit patterned media recording " and "Channel Characterization and Performance Evaluation of Bit-Patterned Media").

|

|

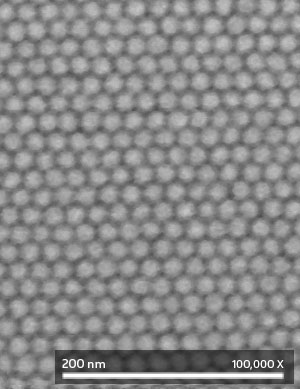

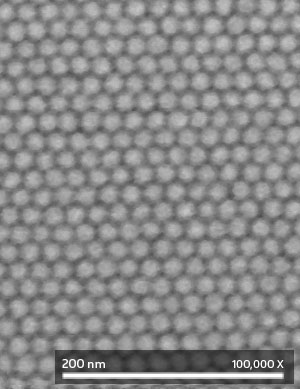

| A scanning electron microscope image of a bit-patterned recording medium, with ordered arrays of magnetic islands. (© 2013 A*STAR Data Storage Institute)

|

|

Conventional hard disk drives store a single data bit in a continuous magnetic medium consisting of many ‘grains’. However, the number (approximately 10–15) and the size of these grains (about 6–10 nanometers) naturally limits the maximum density at which digital information can be stored. The BPMR technique offers much higher storage capacity because it records the data in a regular array of single-grain magnetic islands (see image) that can be much smaller than multiple grain bits in continuous media, according to Lin.

|

|

“Multiple grains must be used per data bit in continuous-media storage,” she explains. “Ideally, bit-patterned media [will] achieve one grain per bit because the magnetic cells are patterned in isolated and ordered arrays known as ‘islands’.”

|

|

A number of practical hurdles, however, are preventing the use of BPMR in computer hard disks. One problem is that the islands are separated by non-magnetic spaces — some 25–65% of the surface only is magnetic. The data can be passed from the writing `head’ only when it is aligned with an island on the spinning disk. Therefore the writing process must be synchronized with the position of the magnetic islands. However, manufacturing defects, variations in disk spinning speed and vibrations can all cause temporal misalignment, which in turn causes writing errors.

|

|

Adding information to the disk that tells the writing head its exact position is one way to correctly time the writing process. This includes synchronization sectors and error correction information; however, this information reduces the capacity of the disk for data storage. Lin and co-workers used computer simulations to theoretically analyze the optimum number of the synchronization sectors. They also analyzed how the additional information would relate to variations in disk spin speed. They investigated the system with read/write spindle motors suffering from high, medium, low and zero speed variation.

|

|

“The analysis indicates that the total additional information needed for synchronization and error correction for a motor with a medium rotation variation is 11.75%,” says Lin. “Compared to the potential gain in terms of data density that this technology enables, such a total overhead is acceptable.”

|