| Posted: May 10, 2012 | |

Graphene quilts take the heat away |

|

| (Nanowerk Spotlight) Gallium Nitride (GaN) is a semiconductor material commonly used in bright light-emitting diodes since the 1990s, which are now found in traffic lights and solid-state lighting. Thanks to its wide band gap, this very hard semiconductor material also finds applications in optoelectronic, high-power and high-frequency devices. For example, GaN can be used to make laser diodes emitting violet color, without use of nonlinear optical frequency-doubling (for instance, GaN-based violet laser diodes are used to read Blu-ray discs). GaN transistors have been offered commercially since 2006. They have found use in various wireless applications due to their high efficiency and high voltage operation. GaN transistors offer advantages in high power electronics, especially in automotive and electric car applications. | |

| However, a severe problem that afflicts high-power GaN electronic and optoelectronic devices is self-heating and the difficulties of heat removal. GaN materials and devices operate at high voltages and can handle high power densities. The unavoidable side product of high power operation is a significant amount of dissipated heat, which leads to an increase of the inside junction temperature, performance degradation and eventual device breakdown. | |

| "To allow for reliable operation of a GaN device, the heat generated near the junction – i.e. active area of the device – has to be removed fast and efficiently," Alexander Balandin, Professor of Electrical Engineering and Founding Chair of Materials Science and Engineering program at University of California-Riverside (UCR), explains to Nanowerk. "Various thermal management solutions such as flip-chip bonding or composite substrates have been attempted. However, temperature rise due to dissipated heat still limits applications of the nitride-based technology." | |

| As they just reported in the May 8, 2012 online edition of Nature Communications ("Graphene quilts for thermal management of high-power GaN transistors"; open access), Balandin together with three of his electrical engineering graduate students (Guanxiong Liu, Zhong Yan and Javed Khan) from his Nano-Device Laboratory (NDL) research group found an unusual solution for the thermal management problem of gallium-nitride technology: They demonstrated that thermal management of GaN transistors can be substantially improved via introduction of alternative heat-escaping channels implemented with graphene multilayers. | |

|

|

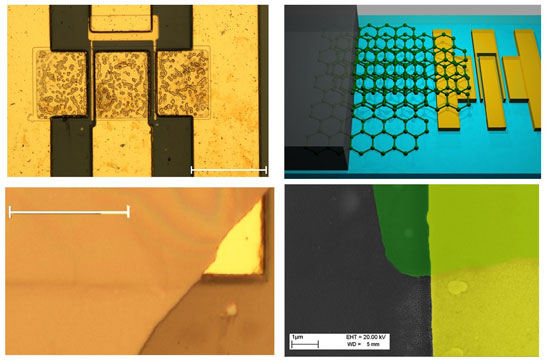

| Figure 1: (clockwise from top left): optical microscopy image of the high-power gallium nitride (GaN) heterostructure field-effect transistor (HFET); schematic of the graphene-graphite quilt on top of the transistor structure for spreading the heat from the local hot spot near the transistor drain; colored scanning electron microscopy (SEM) image of the graphene quilt overlapping transistor; optical microscopy image of the graphene quilt on the device electrode illustrating its flexibility. (Image courtesy of Professor A.A. Balandin, UC Riverside) | |

| The team's new approach to local thermal management of power electronics is conceptually different from conventional techniques in a sense that it specifically targets the hotspots at nanometer and micrometer scale. | |

| "Instead of trying to further reduce the thermal resistance of the whole substrate, we introduce local lateral heat spreaders on top of the GaN device structure, which provide additional heat escape channels from the hotspots," says Balandin. "Ideally, the heat spreader should be made from material with the highest thermal conductivity possible." | |

| Balandin – recipient of IEEE Nanotechnology Pioneer Award for 2011 – has previously discovered that graphene is an excellent heat conductor (see our previous Nanowerk Spotlight: 'Cool' graphene might be ideal for thermal management in nanoelectronics). | |

| Few-layer graphene films preserve their excellent thermal properties even when their thickness is only a few nanometers, which is unlike any metal or semiconductor films. The latter makes them excellent candidates for applications as lateral heat spreaders and interconnects. | |

| In this new work, the Balandin group researchers designed and fabricated graphene-graphite quilts on top of GaN transistors. The graphene-graphite quilts' function was to remove and spread the heat from the hot spots – an opposite of what you expect from the conventional quilts. The term 'graphene-graphite quilts' was to reflect the patched structure of the coating. Using micro-Raman spectroscopy for in situ monitoring, they demonstrated that temperature of the hot spots can be lowered by as much ∼20oC in transistors operating at the large power levels of ∼13 Watts per mm of their width. The revealed temperature reduction translates to an increase in the device life-time by a factor of ten. | |

| "One should also remember that as the technology matures the cost of graphene quilts, which are essentially the layers of carbon, will be much lower than the cost of metals used in electronics," says Balandin. "The chemical-vapor deposition of graphene and few-layer graphene already went commercial." | |

| Computer simulations performed by the group suggest that graphene quilts can perform even better in GaN devices on more thermally resistive substrates. | |

|

|

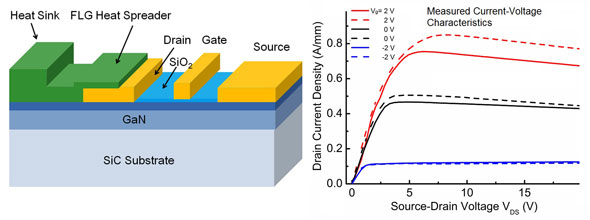

| Figure 2 (left to right): Cross-sectional schematic of the GaN HFET with graphene quilt for heat spreading; current-voltage characteristics of GaN HFET with and without graphene-based heat spreaders demonstrating improvement in the saturation current due to lower junction temperature in the device with graphene quilt. (Image courtesy of Professor A.A. Balandin, UC Riverside) | |

| Balandin notes that the graphene heat spreaders, which help reduce the junction temperature of gallium-nitride high-power transistors, can be combined with graphene-based thermal interface materials. | |

| "In this case, graphene will be offering thermal solution both for lowering the temperature of hot spots and removal of the average dissipated heat from the entire chip" he says. | |

| Nanowerk recently wrote about thermal interface materials with graphene fillers developed in Balandin's group ("Graphene sets new record as the most efficient filler for thermal interface materials"). | |

| The proposed local heat spreading with materials that preserve their thermal properties at nanometer scale, as demonstrated by the UCR team, represents a transformative change in thermal management. The Balandin group is also known in graphene community for their investigation of low-frequency noise in graphene transistors, development of the first large-area method for quality control of graphene and demonstration of the first selective gas sensor implemented with pristine graphene. | |

| The work on thermal management of GaN transistors with graphene quilts was supported by the US Office of Naval Research (ONR). Prof. Balandin's research of the thermal properties of graphene was funded by the Semiconductor Research Corporation (SRC) and the Defense Advanced Research Project Agency (DARPA). | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|