| Sep 26, 2019 | |

A lint roller for superclean graphene |

|

| (Nanowerk Spotlight) One of the most common ways of producing high-quality graphene in sizeable quantities is by chemical vapor deposition (CVD) of methane gas onto a metal substrate, usually copper. In order for the graphene then to be used in its intended application, it needs to be transferred from the growth substrate to a target substrate – a challenging but extremely important process step (read more in our previous Nanowerk Spotlight: "Graphene transfer using an off-the-shelf office laminator"). | |

| Typically the transfer is done by spin-coating a supporting polymer layer and then chemically dissolving away the copper to release the graphene film from the substrate. The transferred graphene produced in this way is prone to contamination from the chemical agents used to remove the growth substrate as well as defective amorphous carbon generated during the high-temperature CVD growth. It also frequently leads to a substantial amount of polymer particle residue on the graphene generated during the transfer process. A third source of contamination could be airborne particles that are adsorbed onto the graphene surface. | |

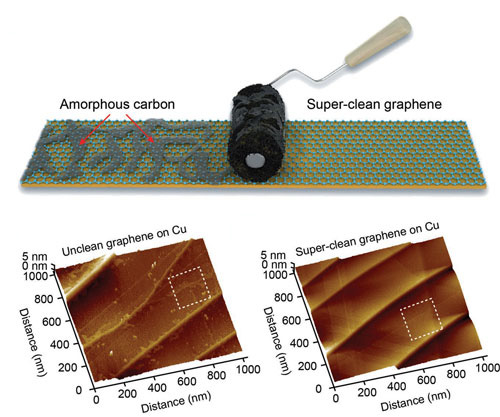

| Researchers have now demonstrated that the amorphous carbon contaminants on CVD-produced graphene, which could greatly degrade its properties, can be removed by an activated carbon-coated lint roller, relying on the strong interactions between the amorphous carbon and activated carbon. | |

| The findings have been published in Advanced Materials ("A Force-Engineered Lint Roller for Superclean Graphene"). | |

| "During the last few years, many efforts have been made to remove surface contaminants from graphene surfaces, which, however, just focused on the removal of the transfer-related polymer residues," Luzhao Sun from Peking University's Center for Nanochemistry, and the paper's first author, tells Nanowerk. "To address this issue, we developed and demonstrated an activated carbon-coated lint roller with a strong adhesive force to successfully remove surface contaminants from graphene. A graphene surface treated with this lint roller exhibits a high cleanliness of 99% with a low degree of polymer residue after transfer onto a functional substrate." | |

|

|

| Superclean graphene treated by the activated carbon-coated lint roller. Top: Schematic of the activated carbon-coated lint roller for cleaning the graphene surface. Bottom left: AFM image of unclean graphene on Cu foil. Bottom right: AFM image of superclean graphene on Cu foil. (Reprinted with permission by Wiley-VCH Verlag) | |

| Inspired by the humble household lint roller – composed of one-sided adhesive paper that interacts strongly with targeted contaminants such as lint on a fabric – the team fabricated an activated carbon-coated roller to treat the graphene/copper foil. This approach relies on the strong interaction between the activated carbon and amorphous carbon present on the graphene. | |

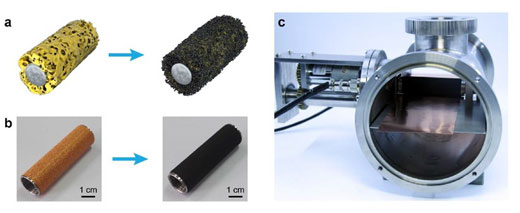

| "We used a binder to coat activated carbon powder on micrometer-sized pores of commercially available copper foam to achieve a high mass loading of activated carbon," Sun explains the device fabrication. "We then conducted the cleaning process of large-area of graphene on copper foil by slowly rolling the foil directly under the activated carbon-coated lint roller at a temperature of no more than 170 °C." | |

| As the researchers demonstrated in their paper, this lint rolling post-treatment results in large-area (meter-scale) superclean graphene surfaces enabled by the strong adhesive force of the activated-carbon-based lint roller on graphene contaminants. | |

|

|

| Fabrication of activated-carbon-containing lint roller. a) schematic of the fabricating process of activated carbon containing lint roller by loading the powder of activated carbon on the Cu foam using binder. b) photographs of the roller which made of Cu foam and activated-carbon-containing lint roller c) The equipment where large area of graphene on Cu foil could be treated by activated-carbon-containing lint roller at vacuum and 170 °C. (Reprinted with permission by Wiley-VCH Verlag) | |

| "Applying our lint roller resulted in graphene with surface cleanness exceeding 99%, that can be transferred to dielectric substrates with significantly reduced polymer residues," Sun notes. "In our experiments, the cleaned graphene yielded ultrahigh carrier mobility of 500 000 cm2 V-1 s-1 and low contact resistance of 118 Ω µm, which is comparable with that of exfoliated graphene." | |

| He points out that the extremely low contact resistance and ultrahigh carrier mobility of superclean graphene would satisfy the requirement of high speed electronics including radio-frequency transistors, Dirac-source field-effect transistors; high-speed optoelectronics such as photodetectors and optical modulators; and epitaxy III-V semiconductors for lighting LED or lasers. | |

| Furthermore, superclean graphene provides an ideal platform to study its intrinsic properties such as in electrocatalysis or electrochemical systems. | |

| The synthesis of superclean graphene, as demonstrated by this work, is but one important step towards the kind of high-quality graphene that is needed for many practical applications. But that alone is not enough: defects, steps, wrinkles and grain boundaries are also important aspects that influence the performance of graphene and they all need to be addressed in order to achieve high-quality graphene film. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|