| Oct 11, 2021 | |

Living optical fibers expand the use of photonics for bioengineering |

|

| (Nanowerk Spotlight) Glass is one of the oldest manufactured materials used by humans and glass making dates back at least 6000 years, long before humans had discovered how to smelt iron. Glasses have been based on the chemical compound silica – silicon dioxide, or quartz – the primary constituent of sand. Soda-lime glass, containing around 70% silica, accounts for around 90% of manufactured glass. | |

| Historically, we are familiar with glasses' decorative use or as window panes, household items, and in optics such as eyeglasses, microscopes and telescopes. More recently, starting in the 1950s, glass has been used in the manufacture of fiber optic cables, a technology that has revolutionized the communications industry and helped ring in the digital revolution. | |

| Fiber optic cables propagate a signal as a pulse of light along a transparent medium, usually glass. This is not only used to transmit information but, for instance in many healthcare and biomedical applications, scientists use optical fibers for sensing applications by shining light into a sample and evaluating the absorbed or transmitted light. | |

| A recent development in this field is optogenetics, a neuromodulation method that uses activation or deactivation of brain cells by illumination with different colors of light in order to treat brain disorders. | |

| Since silica fibers have limited biocompatibility, are not biodegradable, and thus are not very suitable for fields such as optogenetics, researchers have used hydrogels instead to fabricate optical fibers. Hydrogels are composed mostly of water, which is a good light conductor in air media. These light-guiding hydrogels were shown capable of integrating tissues, stimulating cells, and sensing varied phenomena (read more: "Hydrogel implant enables light-based communication with cells inside the body"). | |

| "The problem with hydrogel optical fibers is that once they are fabricated, they can’t be modified, as they are 'cooked' using UV light to make permanent bonds of the materials," Carlos Guimarães, the paper's first author, tells Nanowerk. "We addressed this issue with an interdisciplinary approach that integrates optics, bioengineering, and nanotechnology to make a living optical fiber with many applications, including cancer models, physical force sensing, and covid detection, among others." | |

|

|

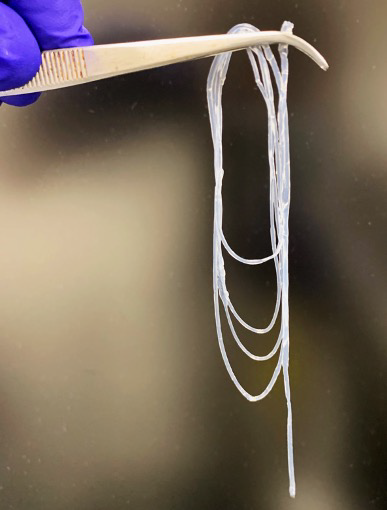

| Photograph of an as-fabricated optical core–clad hydrogel fiber. (Image courtesy of the researchers) | |

| The research team, which includes scientists from the 3B’s Research Group (Biomaterials, Biodegradables and Biomimetics) at the University of Minho in Portugal, and members from the Bio-Acoustic MEMS in Medicine Labs (BAMM) laboratory at at the Canary Center for Early Cancer Detection under the Department of Radiology at The Stanford University School of Medicine, published their findings in Advanced Materials ("Engineering Polysaccharide-Based Hydrogel Photonic Constructs: From Multiscale Detection to the Biofabrication of Living Optical Fibers"). | |

| This work represents a simple and low-cost approach to fabricating optical fibers made from biological materials. These fibers can be easily modified for specific applications and don’t require sophisticated equipment to generate relevant information. This method could be used for many practical sensing and biological modeling applications. | |

| Considering that most cell and tissue analysis is done using methods that are time-consuming and costly, such as sample-destructive methods and staining as well as complex microscopy, this novel approach will digitize biology, allowing to explore complex cell phenomena using a simple light source and collector. | |

| "Moreover, the use of the hydrogel photonic constructs is ideal to understand complex and large-scale phenomena over time, as living entities can proliferate in the engineered environment and form large living structures such as fibroids, and analysis can be done extremely fast and without sample destruction," says Guimarães. "This allows for better tracking of responses but also for great reduction in materials and biological reagents consumption. Additionally, by having a platform made of purely soft, degrading materials can reduce the high use of cell culture plastics currently needed in biological experiments moving towards greener laboratory practices." | |

|

|

| Hydrogel optical fiber under analysis and light guiding. (Image courtesy of the researchers) | |

| "We use a natural, ionic, and biologically compatible crosslinking approach, which enables us to produce flexible hydrogel fibers in continuous multi-layered architectures, meaning they are easy to produce and can be modified after fabrication," explains Guimarães. "Similarly to silica fibers, the core hydrogel of our structures can be exposed, fused to another fiber or reassembled if they break, and efficiently guide light through the established connection." | |

| These flexible hydrogel fibers are made from sugars and work just like solid-state optical fibers used to transmit data. However, they are biocompatible so they can be easily integrated with biological systems. | |

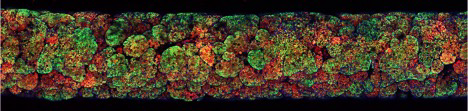

| "We could even consider them to be alive since we can use them to grow living cells inside the fiber," says Guimarães. "As these embedded cells grow over time, we can then use light to inform on living dynamic events, for example to track cancer invasive proliferation into optical information." | |

| The team engineered their wet-spun multi-layer hydrogel fibers with ionic-crosslinked polysaccharides (sugars). These sugars, namely alginate and gellan gum, can be manipulated as liquid precursors, and, when in contact with ions, namely calcium, the electrostatic interactions bind the polymeric chains in a 3D hydrated mesh. These hydrogels have been long studied for tissue engineering and regenerative medicine applications by the 3B’s Research Group led by Prof. Rui Reis. | |

| This present work resulted from an ongoing collaboration between Reis and Prof. Utkan Demirci, who currently directs the Canary Center for Early Cancer Detection under the Department of Radiology at Stanford University School of Medicine. | |

| By using microfluidic-based approaches and 3D printing flow nozzles, this process is strong enough to create flexible hydrogel fibers. | |

| "Even though these materials haven’t been used before to guide light, due to being typically lossy (high water content and low refractive index as opposite to classic silica), we observed that by tuning the concentration of the polymers, it was possible to tune the refractive index slightly yet enough to improve the containment and guidance of light, by using core and coating layers with varying refractive indices, "Guimarães points out. | |

| The characteristics of this novel material allowed the team to easily reconfigure fibers. For example, they can cut them in half and reconstitute them or fuse them with other fibers, creating multi-armed architectures that can branch out and report on 3D force and shape. | |

| Another intriguing aspect of these hydrogel fibers is that their permeable mesh enables the inclusion of biological targets of interest for detection. For example, the scientists observed that fibers were able to soak SARS-CoV-2 viruses, and by integrating nanoparticles for their binding and detection, shifts in visible light could be observed for detecting the accumulation of viral particles within the fiber. | |

| "When light moving through the fiber encounters living cells, it changes its characteristics depending on cellular density, invasive proliferation, expression of molecules, etc." Guimarães notes. "This light-cell interaction can digitize complex biological events, converting responses such as cancer cell progression in 3D environments and susceptibility to drugs into numbers and data, very fast and without the need for sample destruction." | |

|

|

| Longitudinal microscopy image of a fully overtaken fiber core, as unchecked cancer growth leads to the formation of a mature fibroid. (Image courtesy of the researchers) | |

| Having demonstrated this approach in principle by showing the ability to study diverse properties of cells, the team is now looking to push the limits of this method. For instance, they are looking into more specific parameters that could help identify complex cell behavior such as cell metabolism and disease progression. | |

| "In the example of cancer, having multi-compartment hydrogel fibers will allow us to obtain multi-cellular environments where more complex biological models of the cancer micro environment, which we now know is very important for metastasis, can be integrated in the fiber to obtain evermore relevant responses, that can approach the living body," Guimarães explains. "We are also excited to use these fibers to mimic different organs and tissue, e.g., brain (neural tissue), heart (contractile muscle) and gastrointestinal track, as well as other endothelial tissues." | |

| "The future of research in the biomedical area will become more and more reliant upon large data sets and machine learning, thus its necessary to find ways to digitize biology to convert living events more efficiently into quantifiable, measurable data," concludes Demirci, who led this study. "The main challenge of tissue engineering relies on creating more simple universal tools that can generate relevant information while maintaining simplicity and affordability. We see this platform as a tool that can expand access to bioengineering, tissue engineering and in vitro 3D modeling to more scientist around the world." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|