| Feb 09, 2022 | |

Sustainable batteries roadmap to 2030 and beyond |

|

| (Nanowerk Spotlight) Batteries are a key technology for battling carbon dioxide emissions from the transport, power, and industry sectors. To be effective towards that goal, batteries must exhibit ultra-high performance beyond their capabilities today: energy and power performance approaching theoretical limits, outstanding lifetime and reliability, and enhanced safety and environmental sustainability. Furthermore, to be commercially successful, these batteries must support scalability that enables cost-effective large-scale production. | |

| Today's lithium-ion batteries are the most widespread energy storage solution for mobile electronic devices as well as for electromobility. But when it comes to batteries, there are always areas for improvement: batteries that are cheaper, safer, longer lasting, more energy dense, and easily recyclable. | |

|

|

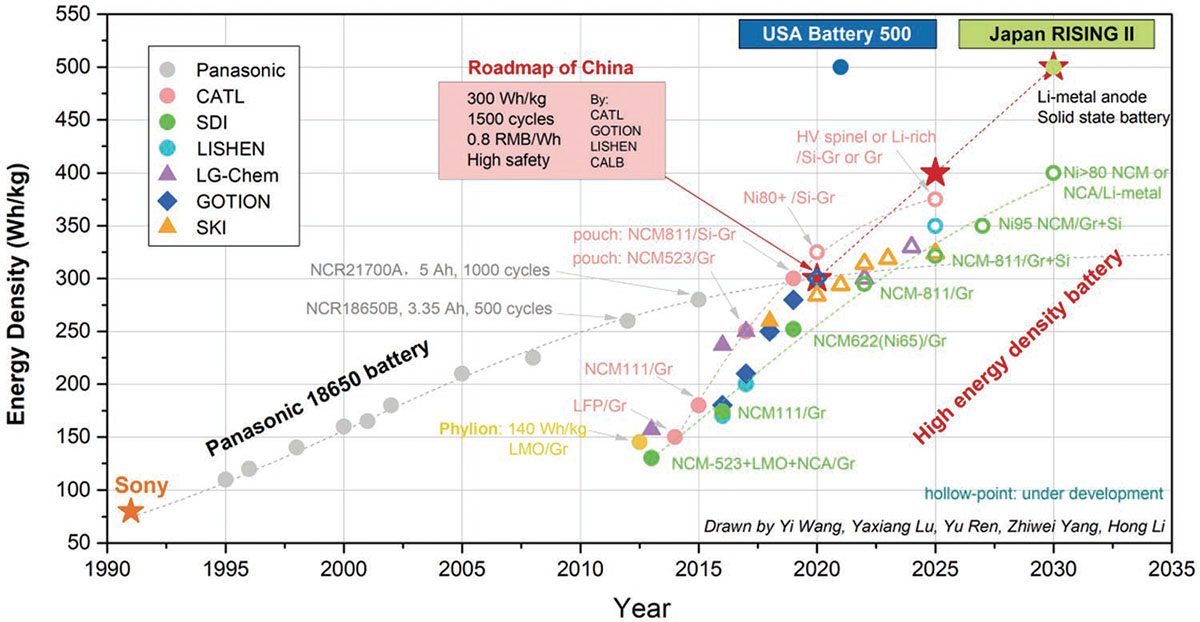

| Performance targets of battery roadmaps published by several associations and countries. Comparison of the gravimetric performance of different batteries for automotive applications. The targets from the Strategic Energy Technology Plan (SET) Plan coincide with the green line (different NCM-based generations of LIBs). Japanese Rising II follows targets similar to those of the SET Plan, while China's targets (red stars) are slightly more ambitious up to 2030. The expectations for the lithium-metal solid-state battery are the same in all roadmaps. Important to remember is that these roadmap are specifically targeting the transport sector so other battery chemistries important for other market segments are omitted. (Reproduced with permission by Wiley-VCH Verlag) (click on image to enlarge) | |

| Enter BATTERY 2030+, a large-scale cross-sectoral European research initiative bringing together the most important stakeholders in the field of battery R&D to create a strong battery research and innovation ecosystem community. A goal of the project is to develop a long-term roadmap for battery research in Europe. This roadmap suggests research actions towards breakthrough technologies to radically transform the way to discover, develop, and design ultra-high-performance, durable, safe, sustainable, and affordable batteries for use in real applications. | |

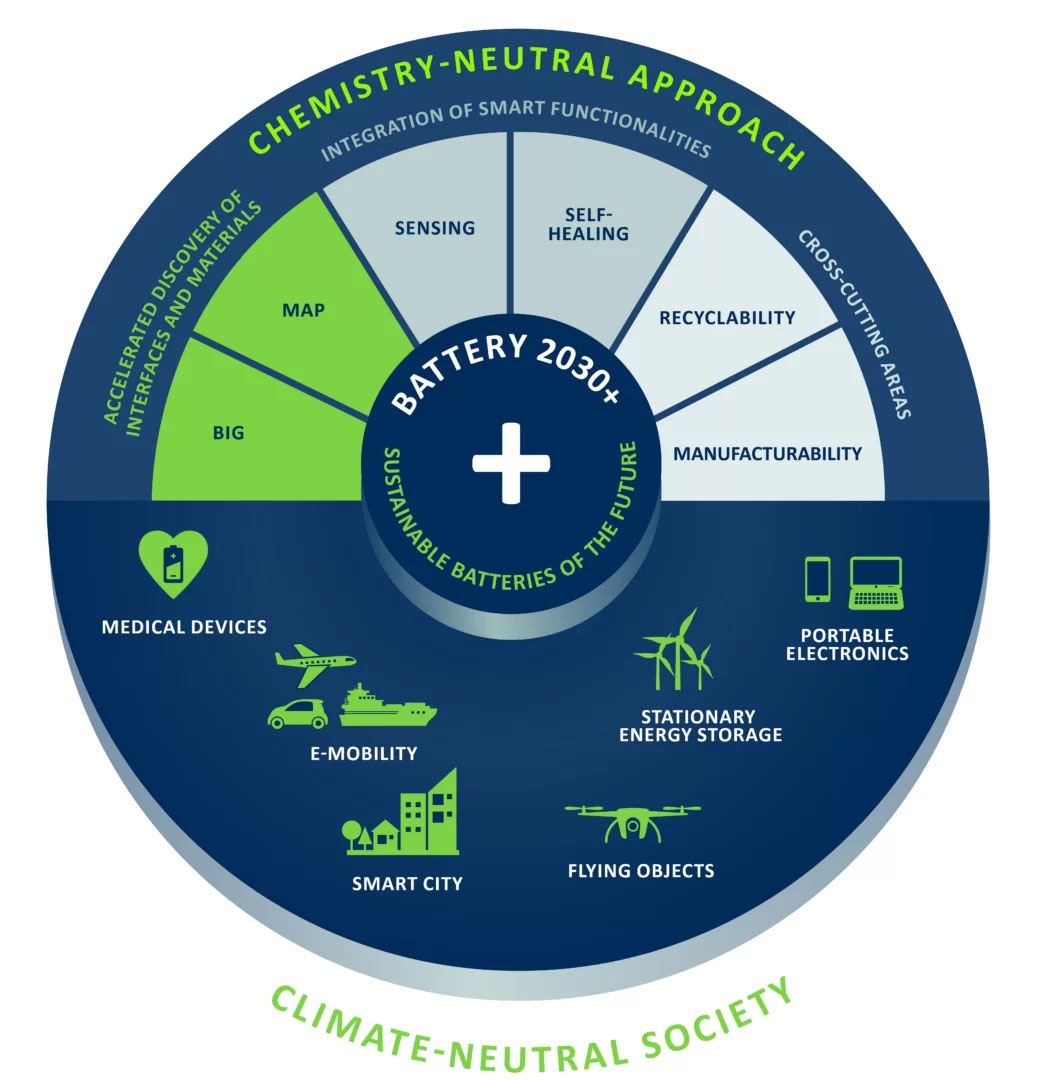

| BATTERY 2030+ follows a chemistry-neutral approach to facilitate the invention of the batteries of the future. Its goal is not to develop a specific battery chemistry, but to create a generic toolbox for transforming the way we develop and design batteries. | |

| Thanks to its chemistry-neutral approach, BATTERY 2030+ has an impact not only on current lithium-based battery chemistries, but also on all other types of batteries. | |

| As a recent review article in Advanced Energy Materials ("A Roadmap for Transforming Research to Invent the Batteries of the Future Designed within the European Large Scale Research Initiative BATTERY 2030+") describes, BATTERY 2030+ focuses on three overarching themes encompassing six research areas to address the key challenges in inventing the sustainable batteries of the future. | |

| The three overarching themes are: Accelerated Discovery of Battery Interfaces and Materials; Integration of Smart Functionalities; and Cross-Cutting Areas. | |

|

|

| The BATTERY 2030+ vision is to invent the sustainable batteries of the future through a chemistry-neutral approach that will deliver ultra-high-performance batteries optimized for their intended applications, such as electro-mobility, stationary storage, medical devices, and robotics. BATTERY 2030+ proposes to focus on three main themes and six research areas that are strongly linked, all contributing new tools for accelerating battery discovery and development. (Reproduced with permission by Wiley-VCH Verlag) | |

| As illustrated in the figure above, the six research areas described in three themes are interlinked, contributing new tools that will transform the way to discover and develop batteries. | |

| The article discusses each area in detail, reports the current status, outlines the challenges, and describes the advances needed to meet the challenges. | |

| Utilizing the possibilities of Artificial Intelligence (AI), BATTERY 2030+ advocates the development of the Battery Interface Genome (BIG) and Materials Acceleration Platform (MAP) initiative to drastically accelerate the development of novel battery materials. | |

| A central aspect of this effort will be the development of a shared European data infrastructure capable of performing autonomous acquisition, handling, and use of data from all domains of the battery development cycle. | |

| MAP and BIG will be powerful tools for discovering new materials and engineering battery interfaces, and in particular will be used to discover or optimize self-healing materials and chemicals. | |

| New cost-effective sensors with high sensitivity and accuracy, integrated at the battery cell level, offer the possibility of 'smart batteries'. BATTERY 2030+ is targeting the integration of these new sensing technologies into the battery management system (BMS), to give a real-time active connection to the self-healing functions and a safer battery with a longer lifetime. | |

| Finally, the development performed in the cross-cutting research areas (i.e., manufacturability and recyclability) will ensure that it will be possible to efficiently manufacture and recycle next-generation battery cells incorporating new materials, engineered interfaces, sensors, and self-healing functionalities. | |

| Across these research areas, the safety and sustainability of newly developed battery technologies will be central guiding principles. The progress in all identified research areas will be essential for inventing batteries with properties that are tailor-made for their specific applications. | |

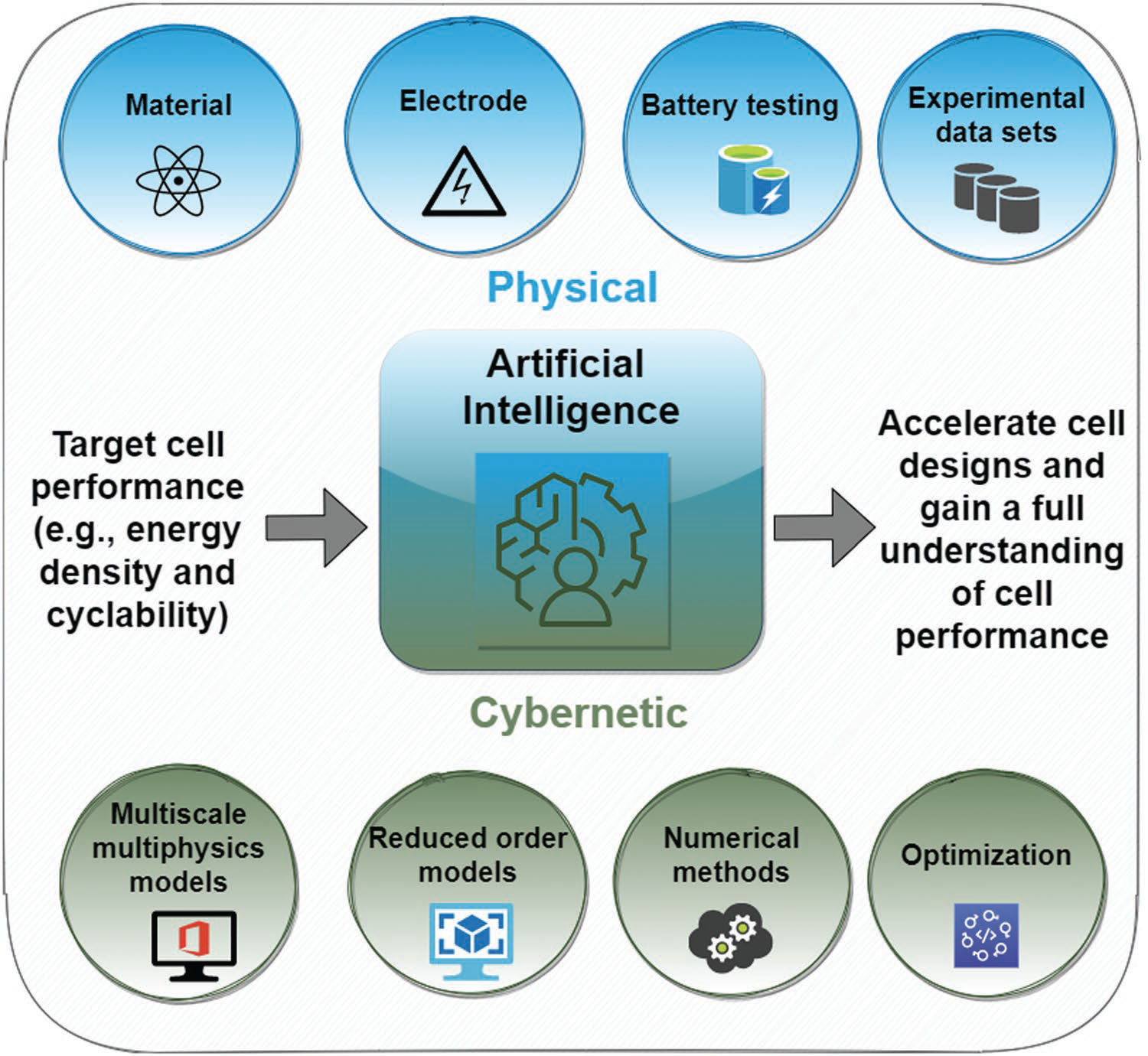

| The manufacturing of future battery technologies is addressed in this roadmap from the standpoint of the fourth industrial revolution, i.e., Industry 4.0 and digitalization. The power of modeling and the use of AI will be exploited to deliver digital twins for both innovative cell designs, avoiding or substantially minimizing classical trial-and-error approaches, and manufacturing methodologies. | |

| This approach would represent a crucial step toward autonomous battery design discovery and optimization, as it connects the desired properties to specific cell configurations, electrode compositions, and material structures as targets to manufacture, characterize, and test. | |

|

|

| Inverse cell design based on digital twin of a cell. (Reproduced with permission by Wiley-VCH Verlag) | |

| Battery cell manufacturing can generally be categorized into three phases: electrode production, cell assembly, and cell finishing. The electrode productions phase comprises several steps, such as mixing, coating, drying, slitting, calendaring, the coating and drying steps being the most cost-intensive processes. | |

| While in the cell assembly phase, steps such as stacking and electrolyte filling are becoming critical, because in general they are the most time and economy consuming. | |

| Finally, in the cell finishing phase, formation and aging of the cells are the most cost-intensive processes, reflecting the challenges of processing time and yield rate. | |

| In summary, the vision for BATTERY 2030+ is to invent the batteries of the future, providing European industry with disruptive technologies and a competitive edge across the full value chain. The groundbreaking science and technology developed by this project will have an invaluable impact on the ongoing transition towards a carbon- neutral and circular economy. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|