| Jun 07, 2022 | |

Emerging 4D printing technologies for biomedical applications |

|

| (Nanowerk Spotlight) Compared to creating static objects with 3D printing, 4D printing systems add time as the fourth dimension to 3D printing: 4D printing allows a 3D printed structure to change its configuration or function with time in response to external stimuli such as temperature, light, water, pH, etc. (read more about the concept here in our previous Nanowerk Spotlight) | |

| The concept of 4D printing is barely 10 years old (the term was first introduced in 2013 in a TED talk) but already researchers have demonstrated a wide range of applications: 4D composite printing that improves the wings of drones, 4D printing with structural colors or the extension of 4D printing to nanophotonics, just to name a few. | |

| Although 4D printing is considered very promising for various biomedical applications – such as tissue scaffolds, neural scaffolds, grafts and stents, cardiac patches and valves, even bionic constructs – its broad-scale adoption for clinical use and tissue engineering purposes is complicated by a notable limitation of printable smart materials and the simplistic nature of achievable responses possible with current sources of stimulation. | |

| A recent review article in Advanced Materials ("Emerging 4D Printing Strategies for Next-Generation Tissue Regeneration and Medical Devices") starts out with a general overview of the state of the 4D printing field, in particular 4D printing technologies, the polymeric materials employed in these technologies, and the design of 4D shape deformation processes (rolling, compression, torsion, stretching, and folding). The authors then summarize representative recent studies on 4D printed biomedical scaffolds/constructs and devices – vascular tissues and stents, cardiac patches and valves, brain constructs, neural scaffolds and conduits, bone scaffolds, muscle scaffolds, and tracheal implants. | |

|

|

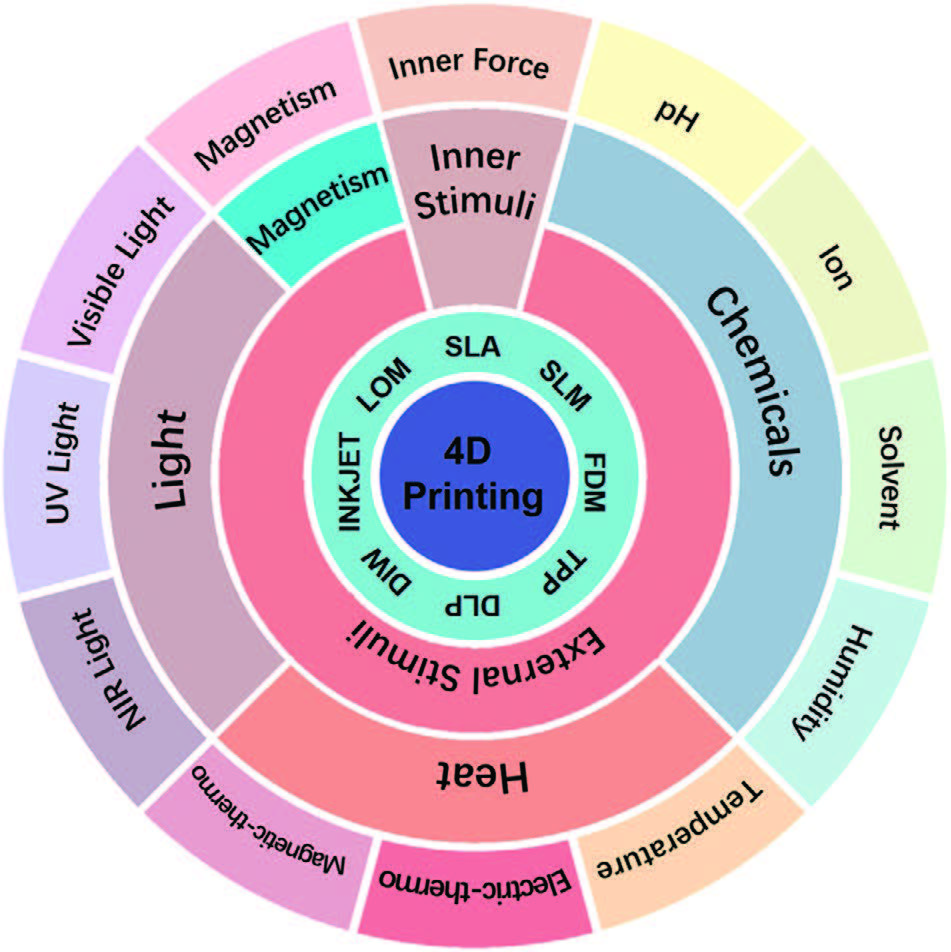

| The manufacturing process of 4D printing is primarily based on existing 3D printing technologies. Classification of 4D printing can be sorted by stimulation sources, including two categories: inner stimuli and external stimuli, and subtypes under five subcategories: inner-, magnetism-, light-, heat-, and chemicals-stimuli. (Reprinted with permission by Wiley-VCH Verlag) | |

| As illustrated above, researchers have used different stimuli-responsive mechanisms to trigger 4D printed architectures, including temperature, chemical induction, light, magnetism, and multi-stimulation sources. | |

| Generally, the most common stimuli used to enact the 4D effect are external: chemical, thermal, light, and magnetism. Internal stimuli typically only refer to inner force-triggered shape deformation that incorporate the 'stress-relaxation' phenomenon during the material manufacturing process. The authors discuss these various stimuli-responsive mechanisms are discussed at length. | |

| On the path towards highly personalize medicine, it is in particular regenerative medicine that has the potential to revolutionize conventional therapeutic strategies by healing or replacing damaged tissues or organs. Within this context, 3D and 4D printing is an innovative biomanufacturing method that can be used to mimic various dynamic processes of living tissues and can facilitate the fabrication of complex tissue/medical products, which can respond to stimulation by complex biological signals, such as bioelectrical or biochemical signals. | |

| Owing to its ability to generate constructs with distinct self-morphing capacities, 4D printing may offer a more favorable fabrication approach over 3D printing, as 4D constructs can respond to internal and/or external stimuli. The unique advantages 4D printing offers for the fabrication of biomedical devices include but are not limited to | |

|

|

|

|

|

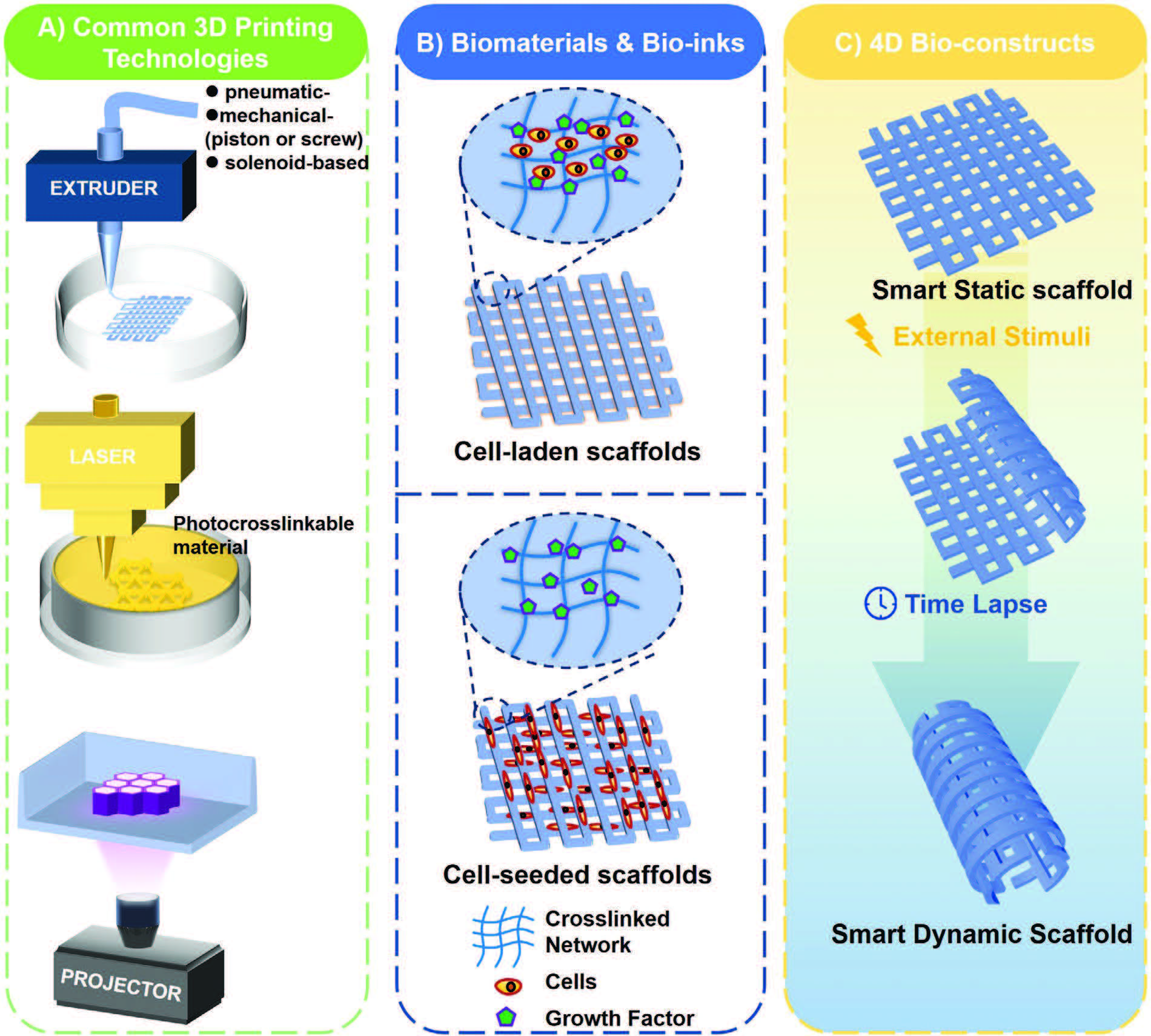

| Schematic illustration of 4D printing for tissue regeneration. A) Most commonly used 4D printing technologies: FDM or DIW, SLA, and DLP. B) Biomaterial and bio-ink strategy applied in tissues/organs regeneration. C) 4D transformation process of the printed scaffolds triggered by external stimuli. (Reprinted with permission by Wiley-VCH Verlag) | |

| The fabrication process of dynamic tissue scaffolds involves the utilization and placement of a 4D ink solution, the filament of a (bio)material, or a mixture of several (bio)materials, which either directly encapsulates desired cells together with growth factors (or loading of cells postprinting). | |

| Generally, there are two types of printed tissue scaffolds, i.e., cell-laden scaffolds and cell-seeded scaffolds. The cell-laden scaffolds are fabricated by the simultaneous deposition of bioinks that consist of biocompatible material and cells. The most commonly used bioink materials include gelatin, collagen, GelMA, alginate, hyaluronic acid (HA), decellularized extracellular matrices (dECMs), and their (methyl)acrylate derives. Cell-seeded scaffolds are easy to produce, as the printed constructs are simply printed, washed, and then topically administered with cell sources and/or growth factors. | |

| Vascular Grafts and Stents | |

| Vascular regeneration and vascular stents represent one of the first biologically relevant applications for 4D printed constructs, as their tubular structure is simple to obtain by a 4D rolling or stretching process. In addition to blood vessels, various tubular structures can be found within the human body, and include tissues such as muscle fibers, nerve bundles, and tendons. | |

| Cardiac Patches and Valves | |

| In contrast to vascular grafts or stents which are mostly tubular in structure, cardiac scaffolds/patches must achieve curved and aligned architectures to effectively attach to the surface of the heart to repair injured myocardial tissue. Compared to 3D printing for cardiovascular regeneration, 4D printing can enable the fabrication of a physiologically relevant curved surface with incorporated dynamic mechanical stimulation. | |

| Bionic Brain Constructs | |

| Through the conversion of patient-specific geometries rendered from diagnostic imaging studies, such as a computed tomography and magnetic resonance imaging, into STL files (STL files have become the de facto standard data transmission format for 3D printing) using specific software and hardware, 3D printing has helped to develop personalized cerebrovascular 3D printed models in the clinical setting. | |

| Superior to 3D printing, 4D printing has great potential for replicating the development of native complex tissue in a manner of spatiotemporal change. For example, the cerebral cortex folding process of the brain can be mimicked via 4D bioprinting. | |

| Another application for 4D printing of brain tissue is to achieve a uniform cell distribution on the wrinkled surface of the brain construct. | |

| Neural Scaffolds and Conduits | |

| Nerve regeneration is a complex, and poorly understood biological phenomenon. Since nerve injuries with a large defect gap have drastically limited regeneration capabilities, nerve graft surgery is usually required. Recently, the artificial nerve graft has become one of the most promising strategies for repairing peripheral nerve injury or spinal cord injury. 3D printing of neural conduits, nerve chips, and nerve patches have been extensively studied to provide new treatments for nerve injuries. | |

| The recent development of 4D printed neural scaffolds illustrates the unique features of 4D printing for neural tissue engineerings, such as dynamic self-enturbulation and seamless integration. | |

| Bone Regeneration | |

| Bone repair is one of the earliest applications of 3D printing in tissue engineering. However, 4D printing of bone scaffolds has significant advantages in their reconfigurable capability for easy implantation with minimally invasive surgery and perfect shape fitting in irregularly shaped bone defects. | |

| Muscle Tissue Regeneration | |

| Skeletal muscle is one of the most abundant tissues in the human body, comprising around 45% of the body mass. 3D printing has emerged as a promising technique that enables the fabrication of engineered muscle tissues with heterogeneous structures and mechanical properties. However, it lacks dynamic mechanical cues such as stretching or folding to generate myogenic alignment and functional maturation. As such, 4D printing has become a promising method to solve this problem. | |

| Trachea Repair | |

| The trachea (windpipe) is a cartilaginous tube that connects the larynx to the bronchi of the lungs, allowing the passage of air. The trachea is surrounded by 16???20 C-shaped rings of hyaline cartilage, which is connected by the tracheal muscle. The generation of a 4D printed trachea is another important application due to its ability to fold into C-shaped rings. Researchers have already demonstrated the excellent therapeutic effect of 4D printing in trachea regeneration. | |

|

|

| A tiny and intricate biomedical structure created with the NEST3D technique that allows to 3D print structures that can be just 200 microns across. Read more. (Image: RMIT University) | |

| The bioproducts and medical devices manufactured by 4D printing or other technologies are subject to regulation by regulatory bodies such as the FDA in the US. With the development of 3D printing technology for biomedical applications, the regulatory requirements have prompted the FDA to create a working group to assess technical and regulatory considerations regarding the 3D printing of medical devices. | |

| To date, there are no available FDA-approved biomedical 4D products. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|