| Oct 13, 2023 | |

Overcoming limitations of hydrogel actuators with graphene microtubes |

|

| (Nanowerk Spotlight) Soft robotics and biomedical devices are pioneering fields that aim to create machinery and tools that mimic the soft, flexible nature of human tissues. This is crucial because it allows these devices to interact safely with humans and perform tasks that hard robots might find challenging. Imagine a robot that can gently grasp delicate objects, or a medical device that seamlessly integrates with human tissues. | |

| Hydrogels are at the forefront of making this possible due to their unique ability to change shape in response to various stimuli. These materials are water-swollen polymer networks that can reversibly change volume in response to stimuli like temperature. This makes them promising as soft actuators – highly elastic devices that deform and exert force, enabling lifelike motion important for biomedical devices and safe human-robot interactions. | |

| However, there have been hurdles in optimizing their performance for real-world applications. Most hydrogels are poroelastic, meaning their polymer networks resist rapid deformation and restrict internal water flow. This causes slow actuation responses on the order of minutes to hours. | |

| Poly(N-isopropylacrylamide) (PNIPAM) hydrogels also form dense outer skin layers when heated above their lower critical solution temperature, which further dramatically slows water diffusion out of the bulk gel. Combined, these effects severely limit achievable speed, force generation and durability of hydrogel actuators. | |

| Now, researchers at Kiel University and collaborators report in Advanced Materials ("Overcoming Water Diffusion Limitations in Hydrogels via Microtubular Graphene Networks for Soft Actuators") a bioinspired micro- and nanoengineering solution to enhance hydrogel actuator performance. | |

| By incorporating an interconnected network of hollow graphene microtubes into PNIPAM hydrogels, the team achieved up to 400% faster actuation and 4000% higher actuation stress compared to pure PNIPAM, without sacrificing mechanical stability. The microtubes provide rapid pathways for water transport, overcoming poroelastic constraints. Graphene also appears to prevent complete pore closure during deswelling, enabling faster reswelling. With only 5.4% porosity, strength is retained. | |

|

|

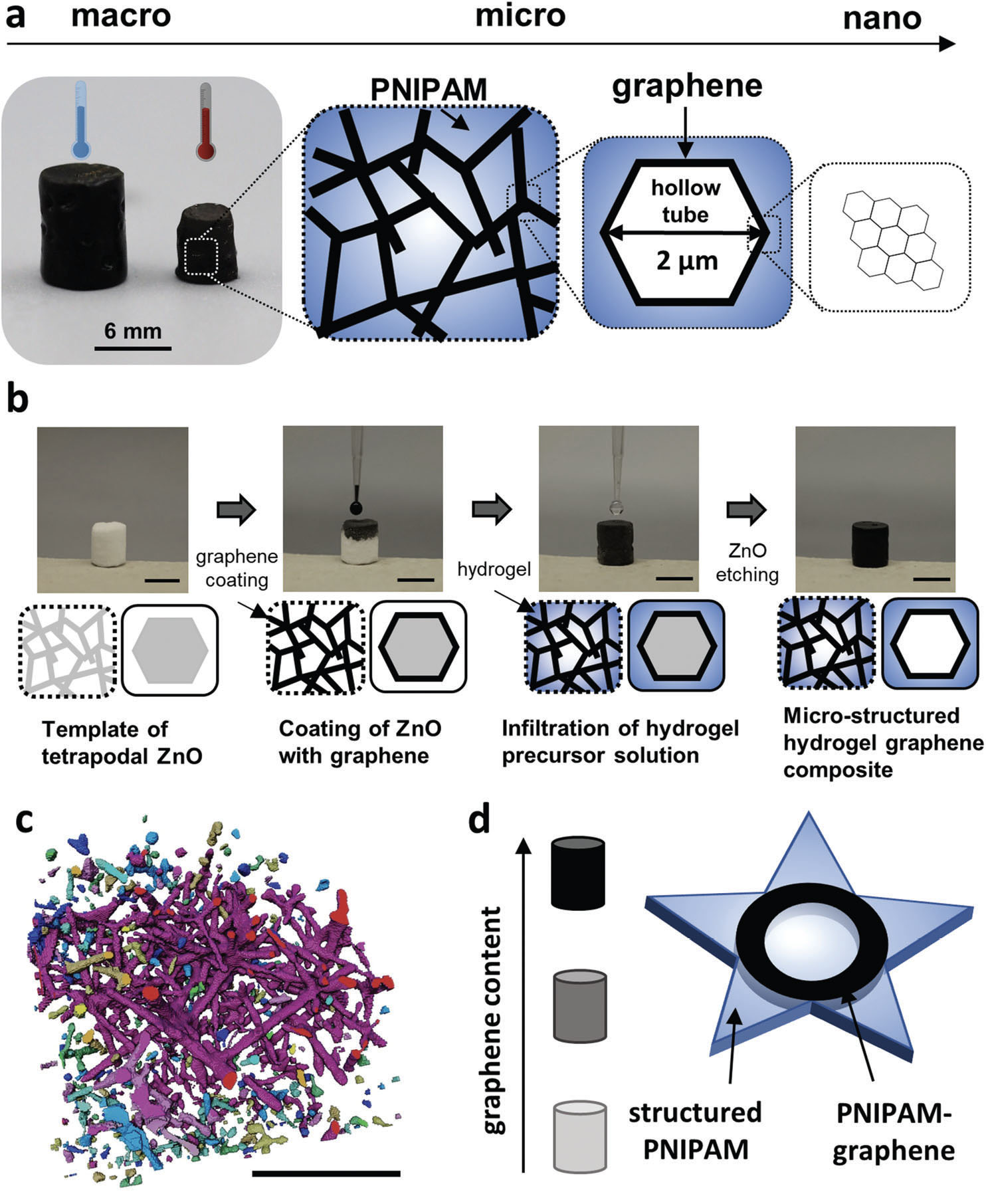

| Micro- and nanoengineered thermoresponsive poly(N-isopropylacrylamide)–exfoliated graphene (PNIPAM–EG) hydrogels. a) Combination of an interconnected hollow graphenemicrotube network and a PNIPAM hydrogelmatrix. b) Fabrication scheme of PNIPAM–EG hydrogels. c) 3D rendering of the microtube network obtained from microcomputed tomography of PNIPAM-structured. Connected components are displayed in the same color. Scale bar: 200 µm. d) The graphene content in PNIPAM–EG hydrogels is adjustable and can be applied to specific regions as a pattern. (Reprinted with permission by Wiley-VCH Verlag) | |

| The team fabricated the microtubes by coating 3D-printed zinc oxide templates with graphene using a wet chemical process. Subsequent template removal and PNIPAM filling yielded centimeter-scale hydrogel actuators pervaded by the microtubes. Besides geometrically enhancing water transport, the graphene interface may also perforate PNIPAM skin layers for easier water movement. | |

| Graphene is electrically conductive and can be heated with light. This lets researchers control the actuation precisely, using either light or electricity. Varying graphene content provided fine control over response times. Demonstrated applications included bilayer grippers triggered by illumination to grasp and release objects. Joule heating rapidly induced homogeneous volume change, enabling repetitive actuation of an electrified hydrogel gripper. | |

| In summary, graphene microtubes made the hydrogels stronger and allowed water to move through them more easily. The modular microengineering approach could likely be extended to other nanomaterials and responsive polymer systems. Demonstrated performance improvements address key limitations that have restricted real-world hydrogel actuator applications. By easing untethered control and enhancing strength, speed and durability, this advance unlocks opportunities in biomedical devices, soft robotics, sensors and beyond. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|