| Feb 09, 2024 | |

Mussle-inspired coating process enables rapid fabrication of wafer-scale nanoparticle films |

|

| (Nanowerk Spotlight) Nanoparticles exhibit intriguing size-dependent optoelectronic properties with applications across biomedicine, energy, sensing and more. However, the exquisite precision synthesizing discrete nanoparticles contrasts sharply with immense difficulty manipulating them over significant lengths. Researchers worldwide have struggled for decades to efficiently organize nanoparticles across wide areas or volumes. Most self-assembly techniques falter from prohibitively slow kinetics and fail to meet industrial manufacturing demands. | |

| The few successes assembling centimeter-scale nanoparticle films rely on multi-day deposition utilizing evaporation, fluidic filtration or intensive layer-by-layer treatment. These sluggish methods cannot achieve the high throughputs of modern roll-to-roll machinery. Additionally, small nanoparticle dimensions below 50 nm introduce intense Brownian motion and electric double layer formation that repel particles from surfaces and severely hinder rapid uniform assembly. These barriers have stymied translation of alluring nanomaterial properties into commercial systems and devices. | |

| Now, researchers from South Korea’s Gwangju Institute of Science and Technology pioneer a technique achieving swift electrostatic assembly of customized nanoparticle monolayers across entire 100 mm silicon wafers. The method hinges on modulating surface charges of both nanoparticle dispersions and target substrates through excess proton delivery. | |

| For example, bare silicon naturally exhibits negative potential under aqueous conditions, electrostatically repelling anionic citrate-capped gold nanoparticles. Introducing protons chemically removes hydroxyl groups from the surface, flipping the charge positive to strongly attract the anionic nanoparticles. | |

| The team published their findings in Advanced Materials ("Proton-Assisted Assembly of Colloidal Nanoparticles into Wafer-Scale Monolayers in Seconds"). | |

|

|

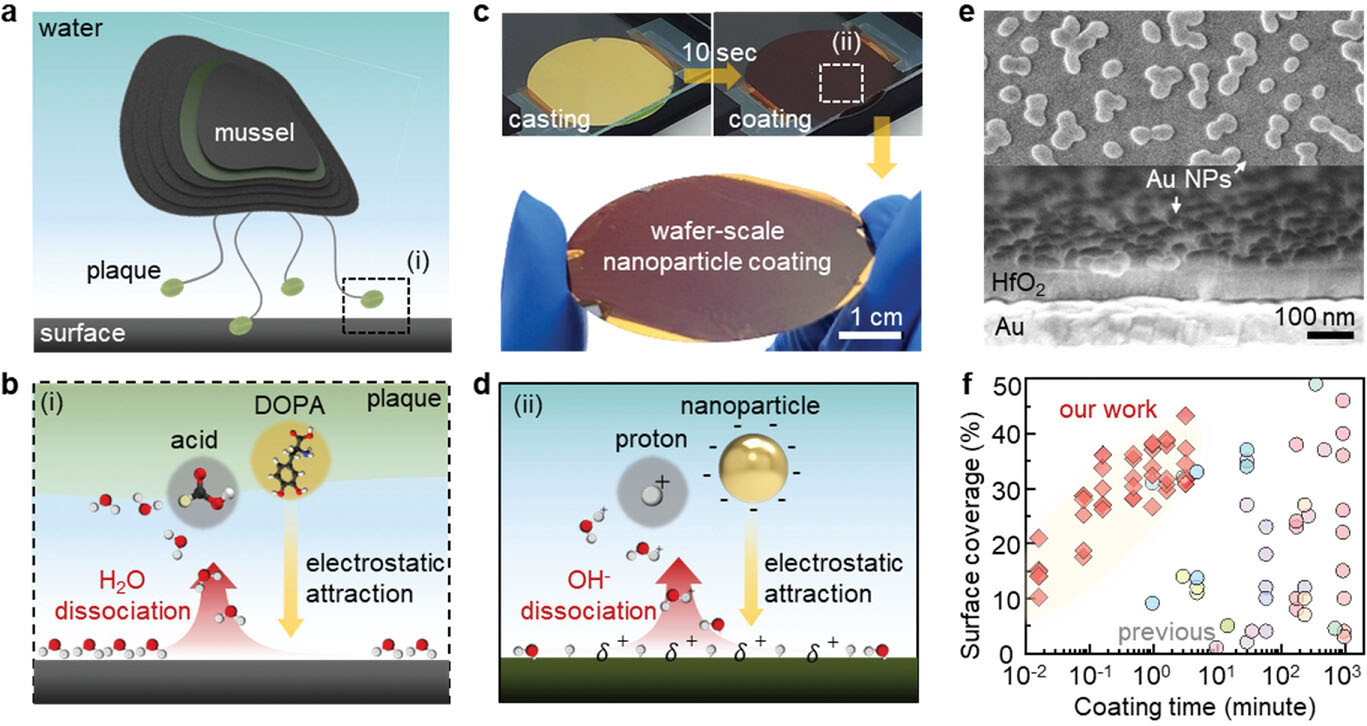

| Concept of mussel-inspired swift nanoparticle assembly. a) Mussel adsorption on the surface in water with b) the mechanism where the acids dissociate water molecules (H2O) from the surface revealing the bare surface that electrostatically attracts DOPA. c) Wafer-scale electrostatic nanoparticle assembly in water over 10 s with d) the mechanism where the protons dissociate hydroxyl groups (OH) from the surface that electrostatically attracts nanoparticles. e) Their scanning electron microscopic (SEM) images (top: projection view, bottom: side view). f) The surface coverage of the nanoparticles versus coating time (red squares: this work, colorful dots: previous works). (Reprinted with permission from Wiley-VCH Verlag) | |

| Carefully tuning acid, salt and nanoparticle concentrations, the researchers tailor Debye screening lengths and electrostatic potentials to balance colloidal stability with intense directed particle migration. Under optimized conditions, exceptional nanoparticle diffusion coefficients exceeding 50 µm2/sec induce rapid nanoparticle transport toward substrates. This enables coating an entire wafer with gold nanoparticles in a dispersion volume under 200 µL within 10 seconds. The resulting films approach maximal surface coverage around 40% in a uniform monolayer configuration. | |

| Such rapid fabrication falls within throughput requirements for scalable roll-to-roll manufacturing. Furthermore, the technique achieves consistent nanoparticle layers across diverse materials like oxides, polymers and 3D-printed plastics without surface pretreatment. This versatile, universal functionality signals a turning point in industrial translation of emerging nanoparticle technologies to benefit sustainability, health and quality of life. | |

| Ongoing limitations that need addressing include batch rather than continuous processing, as well as further optimizing uniformity and spatial control. Nevertheless, this pioneering biomimetic technique merges scientific creativity with real-world application to overcome longstanding barriers and proliferate advanced nanoparticle devices. | |

| This transformative advancement signals a turning point in nanoparticle technology translation, providing a pathway to finally realize sophisticated devices derived from nanoscale building blocks. The creative technique merges scientific innovation with real-world application, epitomizing the power of bioinspired engineering. Ongoing limitations need addressing, but the future looks bright for proliferating advanced nanoparticle-based products to enhance sustainability, health and quality of life worldwide. | |

| The key innovation lies in harnessing excess protons to judiciously modify surface charges. On most materials, abundant surface hydroxyl groups impart an intrinsic negative charge that repels incoming anionic nanoparticles. The researchers found that introducing protons chemically strips away hydroxyls, flipping the surface potential positive to strongly pull in nanoparticles through the water medium. This charge reversal dramatically increases electrostatic attraction forces to accelerate nanoparticle transport. | |

| Carefully tuning colloid ingredients produces nanoparticle diffusion velocities up to 50 µm2/sec, around 100 times faster than conventional values of 0.5 µm2/sec. This rapid transport enables the entire process to complete in mere seconds instead of hours or days. The coating also self-limits to a single monolayer, avoiding uncontrolled multilayer aggregation prevalent in other techniques like drop casting. | |

| Remarkably, the scalable fabrication applies across diverse materials including dielectrics, metals, flexible oxides and 3D printed polymers without surface pretreatments. The researchers demonstrated vibrant, uniform wafer-scale plasmonic metasurfaces producing tunable structural colors. They also integrated functional gold nanoparticle films onto bendable indium tin oxide layers and complex 3D printed objects. | |

| The transformative coating methodology offers tantalizing technological potential. The combination of extreme speed, scalability and universality across surfaces could finally unlock industrial manufacturing of nanoparticle thin films. This would allow commercial translation of exciting nanomaterials into consumer devices and systems. | |

| Ongoing limitations need addressing before widespread adoption, but the initial results showcase compelling capabilities. The technique still relies on lab batch processing instead of a continuous roll-to-roll approach. However, the ultrafast fabrication times already fall within throughput thresholds for scalable production. | |

| Looking forward, further enhancements in speed, yield and spatial control would maximize impact. Using microfluidic reactors could enable continuous high-volume output. Optimizing parameters like nanoparticle concentration and surface functionalization may also improve uniformity. Exploring alternate driving forces such as biomimetic fluid flows could potentially exceed the limits of electrostatics. | |

| Nevertheless, this pioneering research represents a pivotal early step toward next-generation nanoparticle manufacturing. By drawing inspiration from nature, the scientists developed an innovative methodology merging scientific creativity with real-world applicability. Their biomimetic coating technique overcomes longstanding barriers, paving the way for emerging nanotechnologies to transform everyday life through new high-performance products. The lasting contributions may one day spawn widespread applications from flexible electronics to quantum optics that enhance sustainability, health and quality of life for people worldwide. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|