| Apr 20, 2024 | |

Wood-based nanogenerators turn water evaporation into sustainable electricity |

|

| (Nanowerk Spotlight) Water evaporation is a force of nature that has been shaping our planet for billions of years, driving the water cycle and sustaining life on Earth. It is a process that occurs continuously, day and night, across oceans, lakes, and even in the most arid deserts. Yet, despite its ubiquity and immense power, harnessing the energy of evaporating water to generate electricity has remained an elusive goal. The challenges are myriad: the need for materials with high surface area and charge density, the complexity of fabrication processes, and the lack of sustainable, biodegradable options. | |

| The potential of water evaporation as a renewable energy source has long been recognized. Theoretically, water evaporation-induced electricity generators (WEIGs) could provide power densities of up to 10 W/m2, rivaling modern wind power. Moreover, WEIGs can be combined with other renewable energy sources, such as solar and waste heat, to further enhance their efficiency. However, progress in this field has been hindered by the limitations of existing nanomaterials and the complexity of fabrication processes. | |

| Over the past two decades, advancements in nanotechnology have paved the way for the development of nanogenerators capable of harvesting small-scale energy from various sources, such as mechanical strain, physical motion, and differences in temperature or ion concentration. These devices have shown potential as self-powered electronic systems, but their reliance on specific conditions and non-renewable materials has limited their widespread adoption. | |

| In this context, WEIGs have emerged as a promising alternative. By leveraging the electrokinetic effect, which arises from the interaction between functional nanomaterials and water, WEIGs can convert the energy of evaporating water into electricity. Despite these advantages, the development of practical, high-performance WEIGs has been hampered by the complexity of constructing nanomaterials with the necessary surface area and charge characteristics. Additionally, many of the materials used in previous WEIGs have been non-renewable, non-biodegradable, and expensive, making them impractical for remote applications where recovery may be difficult. | |

|

|

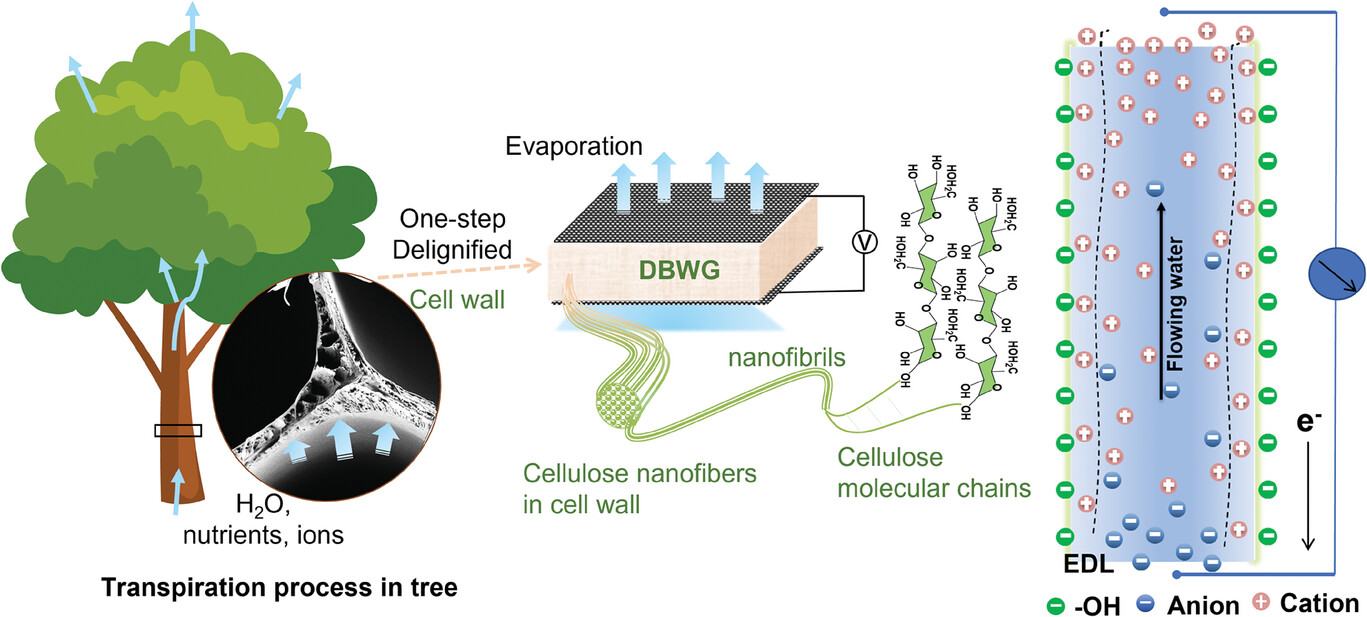

| Schematic illustration of preparation and mechanism of delignified balsa wood-based water evaporation-induced generator (DBWG). The left showed the transpiration of water, nutrients, and ions along the cell of tree; DBW was fabricated by one-step delignification of BW, and DBW retained the hierarchical and porous structure of wood and displayed more exposed CNFs; the hierarchical structure from microscale wood cells, cellulose fibers, CNFs, and molecular-scale cellulose chains were shown; the middle displayed sandwich structure of DBWG (DBW between two electrodes); the right showed the multiphase transportation in DBWG, including water absorption, ions separation, and migration; the electricity generated by DBWG was attributed to streaming potential and electric double layers (EDL). (Reprinted with permission by Wiley-VCH Verlag) | |

| Now, a team of researchers has made a significant breakthrough in this field by developing all wood-based, sustainable WEIGs with high electricity-generating performance. As reported in their paper published in Advanced Functional Materials ("All Wood-Based Water Evaporation-Induced Electricity Generator"), the scientists utilized the intrinsic hierarchical porous structure and aligned cellulose nanofibrils found in natural wood to create efficient ion transport channels. | |

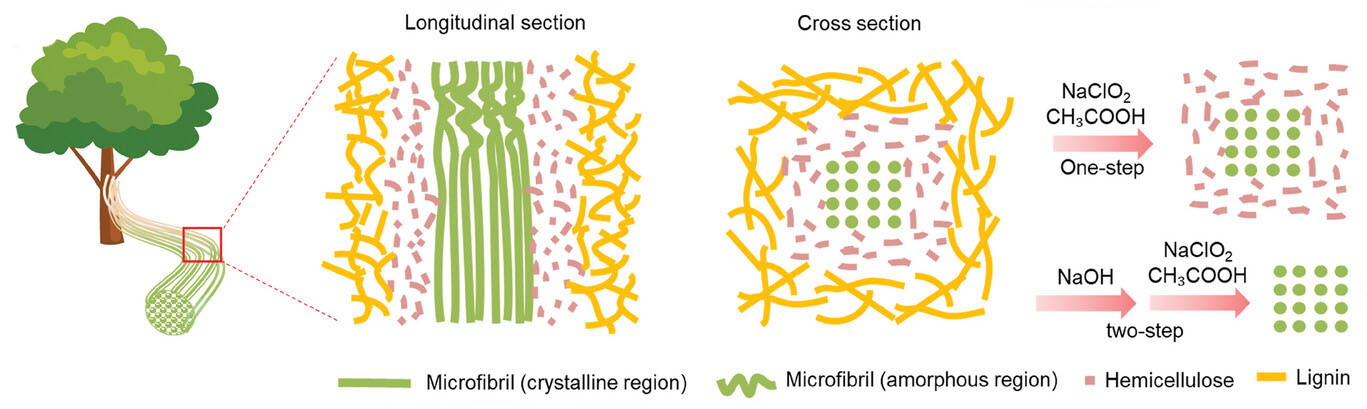

| The researchers chose balsa wood as their starting material due to its high porosity, dimensional stability, and modifiable surface. By removing lignin and hemicellulose from the wood through a process called delignification, they exposed a greater number of vertically aligned, negatively charged cellulose nanofibrils. These nanofibrils served as ion nanofluidic channels, enhancing the power generation efficiency of the wood-based WEIGs. | |

| The delignified balsa wood (DBW) and cellulosic balsa wood (CBW) obtained through this process exhibited significantly increased specific surface area, hydrophilicity, and surface charge density compared to untreated balsa wood. The specific surface areas of DBW and CBW were approximately 1.85 and 4.03 m2/g, which were about 10 and 21 times higher than that of untreated balsa wood (0.19 m2/g). These properties are critical for the selective transport of ions and the formation of an electric double layer at the solid-liquid interface, which gives rise to the streaming potential and current that generate electricity in WEIGs. | |

| In their experiments, the researchers found that both DBW and CBW-based WEIGs displayed dramatically improved power generation performance compared to untreated balsa wood. The DBW-based WEIG (DBWG) demonstrated a stable electricity output and fast responsivity to ambient conditions, such as humidity, temperature, light, and wind. At ambient environments with 40% relative humidity and 26 °C, the DBWG showed an open-circuit voltage of 0.20 V, a short-circuit current of 1.5 µA, and a maximum power of 0.92 µW, which were significantly higher than those of the untreated balsa wood-based WEIG. These characteristics make DBWGs suitable for use as self-powered environmental sensors in addition to their role as power sources. | |

|

|

| The components of wood cell wall were mainly cellulose, lignin, and hemicellulose. Cellulose fibrils consisting of crystalline and amorphous regions were embedded in lignin and hemicellulose matrix. (Reprinted with permission by Wiley-VCH Verlag) | |

| The researchers also investigated the effects of different electrolytes and their concentrations on the performance of DBWGs. By replacing water with salt solutions, they achieved significant enhancements in open-circuit voltage and short-circuit current. A DBWG with a thickness of 2 mm generated an impressive open-circuit voltage of 0.77 V and a short-circuit current of 148 µA when using 1.2 M calcium chloride solution as the electrolyte, which was the optimal concentration for maximizing the device's performance. | |

| While the wood-based WEIGs presented in this study demonstrate significant advancements in terms of sustainability, biodegradability, and power generation efficiency, there are still some limitations and challenges that need to be addressed. For instance, the long-term stability and durability of these devices under various environmental conditions need to be further investigated. Additionally, the scalability of the fabrication process and the integration of these generators with other electronic devices require further exploration. | |

| The potential applications of these wood-based WEIGs are vast, particularly in remote areas where access to a power grid is limited. They could serve as self-powered sensors for monitoring environmental conditions, as well as provide a continuous supply of green electricity for low-power electronic devices. Furthermore, the biodegradable nature of these generators makes them an environmentally friendly alternative to non-renewable energy sources. | |

| As the world seeks to transition towards a more sustainable future, the development of innovative technologies that harness renewable resources is essential. The wood-based WEIGs presented in this research represent a significant step forward in this direction, offering a promising solution for generating green electricity from the ubiquitous process of water evaporation. With further optimization and scaling up, these generators could play a crucial role in meeting the growing demand for sustainable energy and powering the self-powered electronics of the future. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|