| Posted: Mar 30, 2015 |

Split x-ray flash shows rapid processes

|

|

(Nanowerk News) SwissFEL, PSI’s x-ray laser, is to render the individual steps of very rapid processes in materials visible. Usually, this requires two lasers: a conventional one, which triggers the process with a flash of light, and SwissFEL, which x-rays the changed state shortly afterwards with a flash.

|

|

Researchers from the Paul Scherrer Institute have now proposed a new method, where only the flash from the x-ray laser is required as it is split into several parts: one part triggers the change, the other parts reach the material with a delay, where they examine its changed state at different points in time ("Following the dynamics of matter with femtosecond precision using the X-ray streaking method"). One advantage of this new method is that the researchers know the interval between the different parts of a flash with extreme precision. This is important to determine the details of processes that often only last for a few 100 femto-seconds. The researchers tested the technique on the LCLS x-ray laser in the USA.

|

|

X-ray lasers like SwissFEL at PSI should render the individual steps of very rapid changes visible and thus help researchers to understand these changes in detail. These changes can be processes in the human organism or even in a technical device. For instance, the alignment of tiny magnets in a hard drive determines which contents are stored. Today, we know what the interior of the material looks like when data is stored. However, it is unclear what happens in detail while the data contents change. Understanding this process is important for the development of new hard-drive materials.

|

|

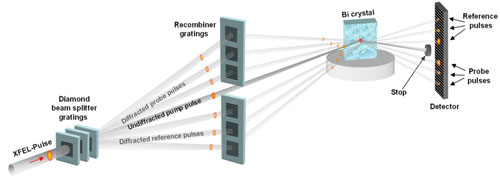

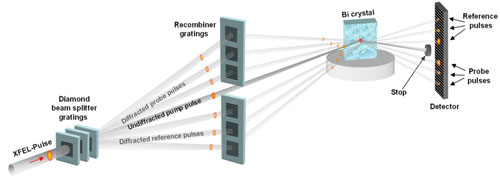

| The principle of the new experimental setup to study rapid processes on the x-ray laser. The x-ray pulse comes from the x-ray laser from the left and passes several lattices arranged one behind the other – small diamond sheets with fine lines etched into them. These lattices split the pulse into several pulses: one intensive main pulse keeps flying straight on while several weaker pulses fly off to the side in different directions (upwards or downwards in the picture). The main pulse is the first to hit the sample being studied, where it triggers a change. The various diverted parts of the x-ray pulse each hit a second lattice, which diverts them again so that they reach the same spot on the sample where the main pulse hit it earlier on (the ones diverted upwards in the picture). As they have covered routes with different lengths, they reach the sample one after the other. These staggered pulses are scattered by the sample and then registered by a detector. The interaction with the sample changes the properties of the x-ray light so that it now contains information on the state of the sample for the moment at which they were scattered. The sum of these staggered pulses thus provides an insight into the timeframe of the processes in the stimulated sample. A second set of diverted beams reaches the sample at a point where the main beam did not hit it and provides information on the behaviour of the sample that was not stimulated as a reference. The “beam stop” catches the scattered main pulse to prevent it from damaging the detector.. (click on image to enlarge)

|

|

Research in the tradition of high-speed photography

|

|

The researchers looking to study these rapid processes are following in the tradition of scientific high-speed photography, which began with Eadweard Muybridge in 1872. The British photographer became the first to depict the detailed motion sequence of a galloping horse, thereby proving that for a brief moment the animal actually lifts all four hooves off the ground. To do so, he set up cameras along the course covered by the horse. These were triggered when the animal tore through a taut thread attached to the shutter release.

|

|

The experiments at SwissFEL will follow a similar principle, which the researchers have dubbed “pump and probe”. The “pump” effectively corresponds to the starting shot that prompts the horse to start running. In many cases, this is a short laser flash, which triggers a change in the arrangement of tiny magnets in the storage material, for instance. The second part – the “probe” – serves to depict the different stages in the development. In Muybridge’s case, these were the cameras; at SwissFEL it will be the short pulses from the x-ray laser that x-ray the material for a certain time after the “pump” and depict the magnetic order at different moments, for example.

|

|

However, the comparison between Muybridge’s arrangement and the classic “pump and probe” falters in one key aspect: while Muybridge took all his pictures during a single run, the SwissFEL researchers are planning to restart the process for every snapshot. This means stimulating the material with a pump pulse and taking a photograph of the current state with an x-ray flash after a certain time before repeating the whole process for the next image, selecting another interval between the pump and the probe. For Muybridge, this would have meant making the horse run repeatedly and only taking one photo each time. The result is a complete depiction of the process over time.

|

|

However, the technique is not without its drawbacks: on the one hand, the researchers have to trust the material examined to behave in the same way every time and return to its initial state reliably before the next pump pulse comes. On the other hand, the pump and probe come from different sources, which makes it difficult to set the interval between them both accurately. Often the processes studied here only last 100 femtoseconds. Consequently, the researchers should be able to set the interval between the two pulses a lot more precisely, which is very tricky. 100 femtoseconds is 0.0000000000001 seconds – so short that the light progresses no more than 0.03 millimetres.

|

|

Splitting x-ray light

|

|

Christian David, a researcher from the Laboratory of Micro and Nanotechnology at the Paul Scherrer Institute, has now presented an alternative method that could enable both disadvantages to be avoided. This is because both pulses – the pump and the probe – not only come from the same source, but even the same x-ray flash, which is generated by the x-ray laser and subsequently divided into several sub-flashes. The largest part flies directly to the material being studied and acts as a pump. A smaller part is sent on a detour, reaches the material with a delay and studies its changed state. As the scientists know the speed of light extremely precisely and can measure the length of the detour accurately, they now know exactly how long the interval is between the two pulses. An additional feature is that not just one, but several sub flashes are diverted, flying detours of different lengths so that the state of the material at different points in time can be studied in one single experiment.

|

|

“We used this method to measure a known structure on the LCLS x-ray laser in California and demonstrated that it works,” says David. “We’re confident that the method will make extremely novel experiments possible.” And he stresses: “The technique won’t replace the conventional pump and probe altogether as it often comes down to the special properties of the pump laser that stimulates the studied material in a specific way.”

|

|

Diamond lattice with line spacing of twenty nanometre

|

|

“Lattices” form the diverting structure’s core – sheets made of diamond measuring around one millimetre by one millimetre, into which fine lines are etched. The spacing between the lines is adjusted to the properties of the x-ray light so that the lattices split the beam into several beams – the main beam, which passes through the lattice, and several side beams, which are diverted in different directions. The diverted beams all hit a second lattice, which diverts the beams again so that they eventually reach the point on the material where the main beam hit it earlier on. This enables the diverted beams to measure the changes at this point.

|

|

Producing optical components that can be used to control the x-ray light is particularly challenging. Conventional mirrors or glass lenses like the ones used for visible light are unsuitable for x-ray light, which means that the scientists have to resort to fine lattices. The researchers from the Laboratory of Micro and Nanotechnology at the Paul Scherrer Institute are among the world’s leading specialists when it comes to the production of such optical components. For the very intensive light from an x-ray laser, the lattices need to be made of diamond as other materials would simply melt.

|