Langmuir-Blodgett (LB) Technique: Creating Ultrathin Ordered Films

What is the Langmuir-Blodgett (LB) Technique?

The Langmuir-Blodgett (LB) technique is a method for depositing organized molecular monolayers or multilayers onto solid substrates. It allows precise control over the thickness and molecular architecture of ultrathin films at the nanoscale. The LB technique is named after Irving Langmuir and Katharine Blodgett, who pioneered this approach in the early 20th century.

Key Steps in the Langmuir-Blodgett Process

The LB technique involves several key steps:

- Spreading of Amphiphilic Molecules: Amphiphilic molecules, which have both hydrophilic and hydrophobic parts, are dissolved in a volatile solvent and spread onto a water subphase in a Langmuir trough. Common amphiphilic molecules used in LB films include fatty acids, lipids, and functionalized polymers.

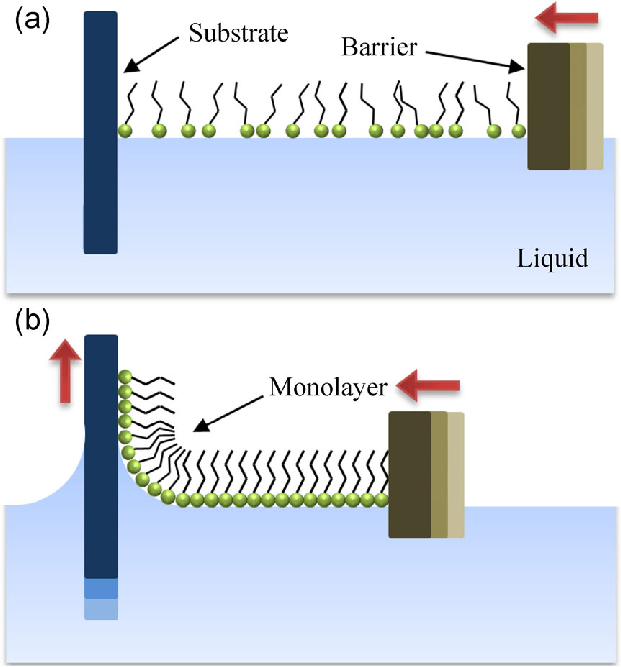

- Compression of the Monolayer: After the solvent evaporates, the amphiphilic molecules are compressed by moving barriers on the water surface. This compression reduces the area available for each molecule, forcing them to organize into a closely packed monolayer called a Langmuir film.

- Transfer onto a Solid Substrate: The solid substrate, which can be hydrophilic or hydrophobic, is dipped vertically through the compressed monolayer. As the substrate is withdrawn, the monolayer is transferred onto its surface, forming an LB film. This process can be repeated to create multilayer LB films with precise control over the number of layers.

Advantages of the Langmuir-Blodgett Technique

The LB technique offers several advantages for fabricating ultrathin ordered films:

- Precise Thickness Control: The thickness of LB films can be controlled with nanometer precision by adjusting the number of layers deposited. Each monolayer typically has a thickness of 2-3 nm, allowing for the creation of ultrathin films with well-defined thicknesses.

- Molecular Orientation Control: The LB technique enables control over the orientation and packing of molecules in the film. By selecting appropriate amphiphilic molecules and optimizing the compression conditions, highly ordered and oriented molecular architectures can be achieved.

- Versatility: The LB technique can be applied to a wide range of amphiphilic molecules, including functionalized molecules with specific properties. This versatility allows for the fabrication of LB films with tailored chemical, optical, and electronic properties.

- Large-Area Deposition: LB films can be deposited onto large-area substrates, making the technique suitable for applications requiring uniform and homogeneous films over extended surfaces.

Applications of Langmuir-Blodgett Films

LB films find applications in various fields, including:

- Sensors and Biosensors: LB films can be functionalized with specific receptors or biomolecules to create highly sensitive and selective sensors for chemical and biological analytes.

- Optoelectronics: LB films with tailored optical properties, such as light-emitting or light-harvesting molecules, can be integrated into optoelectronic devices like organic light-emitting diodes (OLEDs) and solar cells.

- Nanopatterning: LB films can serve as templates or masks for nanopatterning, enabling the fabrication of nanostructures with controlled sizes and shapes.

- Fundamental Studies: LB films provide a platform for studying the properties and behavior of molecules in confined and ordered environments, contributing to the understanding of molecular interactions, charge transport, and energy transfer at the nanoscale.

Challenges and Future Perspectives

Despite the advantages of the LB technique, there are challenges to be addressed for its widespread application. One challenge is the limited stability of some LB films, particularly those made from small molecules, which can be prone to reorganization or degradation over time. Strategies to improve the stability of LB films include the use of cross-linkable molecules or the incorporation of stabilizing layers.

Another challenge is the scalability of the LB technique for large-scale manufacturing. While the technique is suitable for laboratory-scale fabrication, its translation to industrial-scale production requires the development of automated and high-throughput LB deposition systems.

Future research in LB films will focus on exploring new amphiphilic molecules with enhanced properties and functionalities, such as stimuli-responsive or self-healing capabilities. The combination of LB films with other nanomaterials, such as nanoparticles or 2D materials, will also open up new possibilities for creating hybrid nanostructures with synergistic properties.

Further Reading

Applied Sciences, Nanofabrication Techniques in Large-Area Molecular Electronic Devices