Laser Ablation: Precisely Removing and Shaping Materials at the Nanoscale

What is Laser Ablation?

Laser ablation is a process that uses high-energy laser pulses to precisely remove or vaporize materials from a solid surface. When the laser beam focuses on the target material, it absorbs the laser energy, leading to rapid heating, melting, and evaporation of the material. This process can be used to create micro and nanoscale structures, thin films, and nanoparticles with well-defined properties and morphologies.

Key Aspects of Laser Ablation

Several key aspects characterize the laser ablation process:

- Laser Parameters: The laser wavelength, pulse duration, fluence (energy per unit area), and repetition rate play crucial roles in determining the ablation mechanism and the resulting material properties. Ultrashort pulsed lasers (femtosecond and picosecond) are often used for precise ablation with minimal heat-affected zones.

- Material Properties: The target material's optical, thermal, and mechanical properties influence its interaction with the laser beam. Factors such as absorption coefficient, thermal conductivity, and melting point determine the ablation threshold and the material's response to laser irradiation.

- Ablation Mechanisms: Laser ablation can involve various mechanisms, including thermal vaporization, photochemical decomposition, and plasma formation. The dominant mechanism depends on the laser parameters and material properties, and it affects the ablation rate, surface morphology, and the composition of the ablated material.

Types of Laser Ablation

Laser ablation can be categorized into different types based on the specific application and the environment in which the process takes place:

Direct Laser Ablation

Direct laser ablation involves focusing the laser beam directly onto the target material in a controlled atmosphere or vacuum. This approach is used for precise material removal, surface patterning, and the fabrication of micro and nanostructures. Direct laser ablation is widely employed in applications such as micromachining, surface texturing, and the production of high-quality thin films.

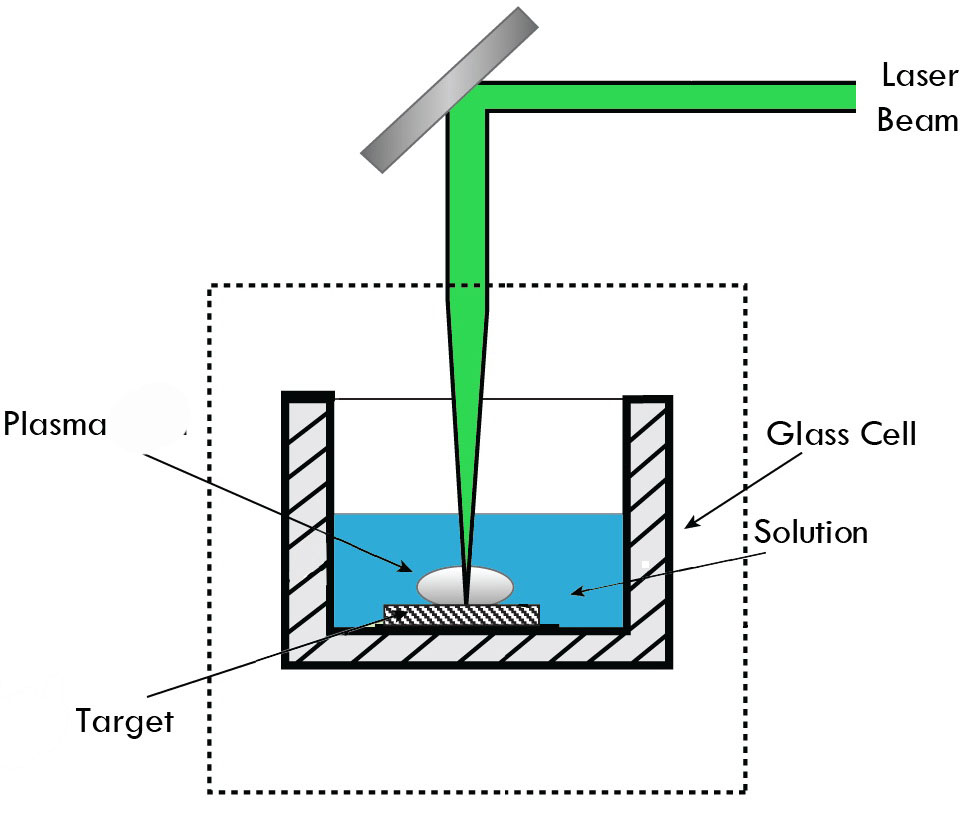

Laser Ablation in Liquids (LAL)

Laser ablation in liquids (LAL) is a technique where the target material is immersed in a liquid medium, and the laser beam is focused through the liquid onto the material's surface. LAL is particularly useful for the synthesis of colloidal nanoparticles, as the liquid environment provides confinement and stabilization for the ablated material. By selecting appropriate liquid media and laser parameters, LAL enables the production of nanoparticles with controlled size, shape, and composition.

Matrix-Assisted Laser Desorption/Ionization (MALDI)

Matrix-assisted laser desorption/ionization (MALDI) is a soft ionization technique used in mass spectrometry for the analysis of large biomolecules, such as proteins and polymers. In MALDI, the sample is co-crystallized with a matrix material that absorbs the laser energy and facilitates the desorption and ionization of the analyte molecules. MALDI enables the gentle and efficient ionization of fragile biomolecules, making it a powerful tool for proteomics and polymer analysis.

Applications of Laser Ablation

Laser ablation finds applications in a wide range of fields, from materials processing and nanofabrication to chemical analysis and biomedical research:

Nanofabrication

Laser ablation is extensively used in nanofabrication for the creation of micro and nanostructures, such as nanowires, nanorods, and nanodots. By controlling the laser parameters and the ablation environment, it is possible to fabricate nanostructures with desired sizes, shapes, and compositions. Laser ablation also enables the patterning of surfaces with nanoscale resolution, which is essential for the development of miniaturized devices and sensors.

Thin Film Deposition

Laser ablation is a versatile technique for the deposition of high-quality thin films. By ablating a target material and collecting the ablated species on a substrate, it is possible to grow thin films with precise thickness control and uniform coverage. Pulsed laser deposition (PLD) is a particularly popular method for the growth of complex oxide thin films, such as superconductors and ferroelectrics, which are challenging to deposit using conventional techniques.

Nanoparticle Synthesis

Laser ablation in liquids (LAL) has emerged as a powerful method for the synthesis of colloidal nanoparticles. By ablating a target material immersed in a liquid medium, LAL produces nanoparticles with tailored sizes, shapes, and compositions. This approach offers several advantages over chemical synthesis methods, including high purity, ease of control, and the ability to produce nanoparticles from a wide range of materials, including metals, semiconductors, and ceramics.

Chemical Analysis

Laser ablation is employed in various analytical techniques, such as laser-induced breakdown spectroscopy (LIBS) and laser ablation inductively coupled plasma mass spectrometry (LA-ICP-MS). These techniques rely on the ablation of a sample and the subsequent analysis of the ablated material using optical or mass spectrometric methods. Laser ablation-based analytical techniques offer high sensitivity, spatial resolution, and the ability to analyze solid samples directly, without the need for complex sample preparation.

Challenges and Future Perspectives

Despite the significant progress in laser ablation technology, several challenges remain to be addressed. One of the main challenges is the precise control over the ablation process to achieve reproducible and uniform results. The complex interplay between laser parameters, material properties, and the ablation environment necessitates a deep understanding of the underlying physical mechanisms and the development of advanced process control strategies.

Future research in laser ablation will focus on the optimization of the process for specific applications, such as the fabrication of novel nanostructures and the synthesis of advanced nanomaterials. The integration of laser ablation with other techniques, such as self-assembly and surface functionalization, will enable the creation of multifunctional nanostructures with enhanced properties. Additionally, the development of in situ characterization methods and computational modeling tools will provide valuable insights into the ablation process and guide the design of improved laser ablation systems.

Further Reading

Procedia Manufacturing, Laser Ablation of Polymers: A Review

Applied Physics A, Laser ablation research and development: 60 years strong

KONA Powder and Particle Journal, Synthesis of Nanoparticles by Laser Ablation: A Review