X-ray Reflectometry (XRR): Unveiling Nanoscale Thin Film Properties

What is X-ray Reflectometry (XRR)?

X-ray reflectometry (XRR) is a powerful analytical technique used to characterize the structural properties of thin films and multilayered materials at the nanoscale. It involves directing a beam of X-rays onto a flat surface at grazing incidence angles and measuring the intensity of the reflected X-rays as a function of the incident angle or wavelength. By analyzing the reflected X-ray intensity profile, researchers can obtain valuable information about the thickness, density, and roughness of thin film layers with nanometer precision.

Principles of X-ray Reflectometry

XRR is based on the fundamental principles of X-ray reflection and interference. When an X-ray beam strikes a flat surface at a grazing angle, part of the beam is reflected from the surface, while the remaining portion penetrates the material and undergoes reflection at the interfaces between different layers. The reflected X-rays from different interfaces interfere with each other, resulting in a characteristic oscillation pattern in the reflected intensity profile, known as Kiessig fringes.

The period and amplitude of these oscillations contain information about the thickness and density of the thin film layers. The thickness can be determined from the angular positions of the Kiessig fringes, while the density is related to the critical angle below which total external reflection occurs. Additionally, the decay of the oscillation amplitude provides insights into the roughness of the interfaces between layers.

Advantages of X-ray Reflectometry

XRR offers several advantages over other thin film characterization techniques:

- Non-destructive: XRR is a non-contact and non-destructive technique, allowing for the repeated analysis of samples without causing any damage.

- High resolution: XRR can measure film thicknesses ranging from a few Ångstroms to several hundred nanometers with sub-nanometer precision.

- Depth profiling: XRR provides information about the depth-dependent properties of multilayered structures, enabling the analysis of complex thin film systems.

- Versatility: XRR can be applied to a wide range of materials, including metals, semiconductors, oxides, and polymers, as long as they form smooth and flat surfaces.

Technical Specifications

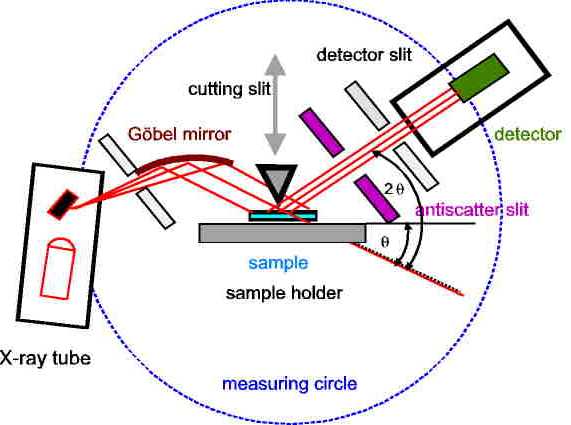

XRR measurements are typically performed using laboratory-based X-ray sources, such as copper (Cu) or molybdenum (Mo) X-ray tubes, which provide a well-defined and monochromatic X-ray beam. The X-ray wavelength is selected based on the material under investigation and the desired penetration depth. For example, Cu Kα radiation (wavelength = 0.154 nm) is commonly used for thin film characterization due to its high intensity and suitable penetration depth.

The reflected X-rays are detected using specialized X-ray detectors, such as solid-state detectors or position-sensitive detectors. These detectors have high sensitivity and spatial resolution, enabling the accurate measurement of the reflected X-ray intensity as a function of the incident angle. Advanced XRR systems may also incorporate optics, such as Göbel mirrors or multilayer monochromators, to further improve the X-ray beam quality and resolution.

Comparative Analysis

XRR complements other nanoscale characterization techniques, such as neutron reflectometry (NR), transmission electron microscopy (TEM) and atomic force microscopy (AFM). NR is a powerful technique that provides similar information to XRR but utilizes neutrons instead of X-rays. Neutrons have unique properties, such as sensitivity to light elements (e.g., hydrogen) and the ability to distinguish between isotopes, making NR particularly useful for studying organic thin films, polymers, and magnetic materials.

While XRR is sensitive to electron density variations, NR is sensitive to nuclear scattering length density differences. This complementary sensitivity allows NR to probe the composition and structure of thin films that may be challenging for XRR. However, NR measurements typically require access to specialized neutron sources, such as nuclear reactors or spallation sources, which can limit its accessibility compared to laboratory-based XRR instruments.

TEM provides high-resolution imaging and structural analysis of thin films but requires extensive sample preparation and is destructive in nature. AFM offers surface topography information with nanometer resolution but lacks the ability to probe the internal structure of thin films.

In comparison, XRR is a non-destructive technique that provides both thickness and density information without the need for complex sample preparation. It is particularly advantageous for characterizing buried interfaces and multilayered structures, which are challenging to access with TEM or AFM. XRR's ability to provide depth-dependent information makes it a preferred choice for investigating the structural properties of thin films in a non-invasive manner.

Applications of X-ray Reflectometry

XRR finds extensive applications in various fields where thin film characterization is crucial:

Semiconductor Industry

XRR is widely used in the semiconductor industry to characterize the thickness, density, and roughness of thin films used in integrated circuits, such as gate oxides, diffusion barriers, and metal interconnects. It enables precise control over the fabrication process and ensures the reliability and performance of semiconductor devices.

Magnetic Thin Films

XRR is employed to study the structural properties of magnetic thin films and multilayers used in spintronic devices, such as magnetic random-access memory (MRAM) and giant magnetoresistance (GMR) sensors. It provides valuable insights into the thickness, interface quality, and magnetic coupling between layers.

Optical Coatings

XRR is used to characterize the thickness and uniformity of optical coatings, such as anti-reflection coatings, mirror coatings, and interference filters. It helps optimize the optical performance and durability of these coatings for various applications, including optics, photonics, and solar cells.

Biomaterials and Biosensors

XRR is applied to study the structure and thickness of biomolecular films, such as proteins, lipids, and nucleic acids, adsorbed on solid surfaces. It contributes to the development of biosensors, drug delivery systems, and biocompatible materials by providing insights into the organization and interactions of biomolecules at interfaces.

Case Studies and Examples

Characterization of High-k Dielectric Thin Films

In the semiconductor industry, XRR has played a crucial role in the development of high-k dielectric materials for advanced gate stacks in transistors. For example, researchers used XRR to characterize the thickness and density of hafnium oxide (HfO2) thin films deposited on silicon substrates. By optimizing the deposition conditions based on XRR results, they achieved uniform and dense HfO2 films with a thickness of only a few nanometers, enabling the fabrication of high-performance and low-power transistors.

Studying Biomolecular Adsorption on Surfaces

XRR has been successfully applied to investigate the adsorption behavior of biomolecules on solid surfaces, which is essential for the development of biosensors and biomedical devices. In one study, researchers used XRR to monitor the adsorption of proteins on functionalized gold surfaces. By analyzing the changes in the XRR profiles, they determined the thickness, density, and conformational changes of the adsorbed protein layers. This information provided valuable insights into the protein-surface interactions and helped optimize the surface functionalization for improved biosensor performance.

Challenges and Future Perspectives

While XRR is a powerful technique for thin film characterization, it also faces some challenges. One of the main limitations is the requirement for smooth and flat surfaces, as surface roughness can significantly affect the reflected X-ray intensity and complicate data analysis. Additionally, the interpretation of XRR data for complex multilayered structures with many interfaces can be challenging and may require advanced modeling and fitting techniques.

Future advancements in XRR instrumentation and data analysis methods are expected to enhance its capabilities and expand its applications. The development of high-intensity X-ray sources, such as synchrotron radiation facilities, will enable faster and more sensitive XRR measurements. The integration of XRR with complementary techniques, such as X-ray diffraction and X-ray fluorescence, will provide a more comprehensive understanding of thin film properties. Furthermore, the application of machine learning algorithms to XRR data analysis will facilitate the rapid and accurate characterization of complex thin film systems.

Further Reading

Journal of Physics D: Applied Physics, Energy dispersive x-ray reflectometry as a unique laboratory tool for investigating morphological properties of layered systems and devices

Zeitschrift für Physikalische Chemie, X-ray Reflectometry and Related Surface Near X-ray Scattering Methods

JPhysics Reports, Theoretical foundation of X-ray and neutron reflectometry