| Feb 14, 2022 |

Engineered nanoparticle release from personal protective clothing

(Nanowerk News) In a toxicological context, exposure to engineered nanomaterials such as nanoparticles or carbon nanotubes primarily occurs through dermal, inhalation, ingestion or injection routes. Among engineered nanomaterials, metal oxide nanoparticles are manufactured in large quantities and used in numerous consumer products such as food, cosmetics, fuels, clothing as well as biomedical applications. This wide use increases the risk of human exposure to these materials.

|

|

There is an increasing use of nanoparticles in clothing. The military, for instance, has been developing a nanotube-based fabric that repels chemical and biological agents.

|

|

A first generation of nano-enhanced textiles benefitted from nano finishing: Coating the surface of textiles and clothing with nanoparticles is an approach to the production of highly active surfaces to have UV-blocking, antimicrobial, antistatic, flame retardant, water and oil repellent, wrinkle resistant, and self-cleaning properties.

|

|

So far, there have been no published studies that evaluate the severity of engineered nanoparticles (ENPs) exposure associated with commonly available protective clothing fabrics or determine the affecting factors for contamination and resuspension of ENPs from the contaminated clothing.

|

|

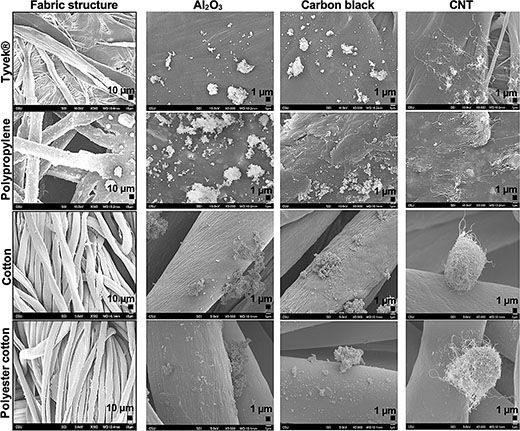

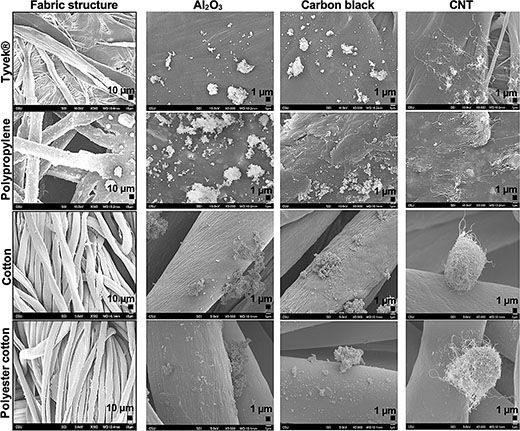

| SEM images of the structure of each type of fabric and surface of the fabrics contaminated with three types of engineered nanoparticles. (click on image to enlarge)

|

|

To address this gap, scientists studied potential exposure contributed by human activities when wearing the ENP-contaminated personal protective clothing and quantitatively evaluate relative ENP retention to each fabric type.

|

|

The findings were reported in ACS Applied Nano Materials ("Engineered Nanoparticle Release from Personal Protective Clothing: Implications for Inhalation Exposure").

|

|

The research team from Colorado State University evaluated the primary factors responsible for ENP adhesion and release from fabrics and identify optimal fabric characteristics for protection against toxic ENPs.

|

|

For their study, the scientists performed two evaluations that include 1) ENP potential exposure at the breathing zone associated with simulated motions of workers walking with various contaminated protective clothing; and 2) qualitative evaluation regarding the characteristics attributed to ENP adhesion, retention, and resuspension from these fabrics.

|

|

This study showed substantial particle release results for all types of tested fabrics.

|

|

The release concentration for cotton and polyester cotton fabric was determined to be the highest from the aerosolization of Al2O3 and carbon black ENPs, while Tyvek and polypropylene showed the lowest amount of release concentration. From the exposure of carbon nanotube ENPs, the cotton fabric showed the highest release concentration compared with other tested fabrics.

|

|

The release concentrations of cotton and polyester cotton were significantly different from Tyvek and polypropylene for Al2O3 and carbon black ENPs, while for carbon nanotube ENPs, cotton fabric turned out to be significantly different from all other fabric.

|

|

Moreover, for all types of tested fabrics, the total number concentrations of resuspended ENPs at the breathing zone are higher than particles released from the back side of the worker wearing the contaminated protective clothing.

|

|

According to the authors, cotton and polyester cotton lab coats were found to be the least effective fabric type for trapping ENPs. Although these fabrics are the most durable, comfortable, and commonly used in workplaces, they are not recommended to be used when ENPs are present in work environments.

|

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC