| Aug 23, 2022 |

Defect-engineering MOFs for properties and performance

(Nanowerk News) Metal-organic framework (MOF) nanocrystals are hybrid materials, built from metal clusters and organic linkers with an almost unlimited number of possible combinations. Their properties and functions are determined by the way they are grown. The vast diversity of shapes and sizes of MOFs, and especially their exceptional porosity and chemical tunability – which affords the adsorption, encapsulation, or release of versatile guest molecules – gives rise to their physical and chemical properties, paving the way for applications in sensing technologies, drug delivery, gas capture, or catalysis.

|

|

In the context of controlling the material properties, another factor plays a crucial role in crystalline nanomaterials: the presence of defects. Defect engineering opens pathways to locally tune the intrinsic porosity, create open metal sites, and modulate the surface properties of MOFs, which has significant implications for separation, gas capture, catalysis, and mechanical responses.

|

|

Previously, for instance, researchers have shown that a MOF was faster at soaking up perfluorooctanesulfonic acid (PFOS) from polluted water, and that it could hold more PFOS, when additional nanometer-sized holes, i.e. defects, were built into the MOF (read more: "Defects help MOF nanomaterial soak up more pollutant in less time"). The nanocrystal used in this work was UiO-66, which has become somewhat of a model system for defective MOFs.

|

|

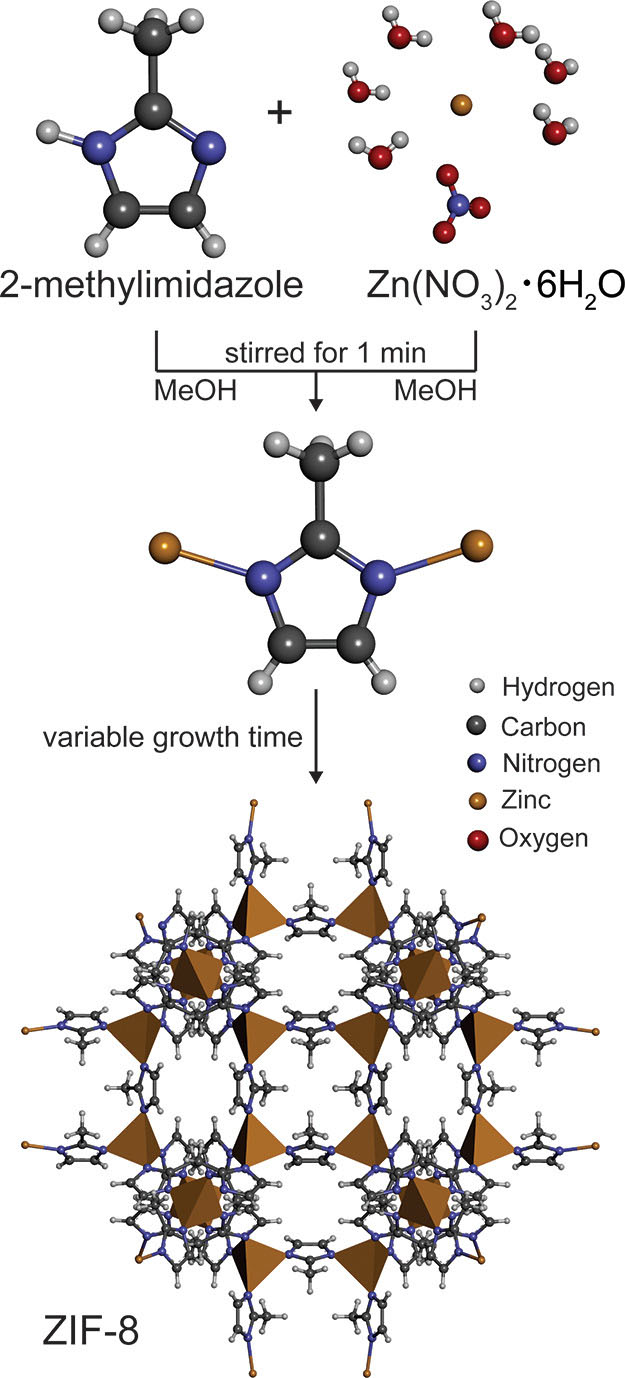

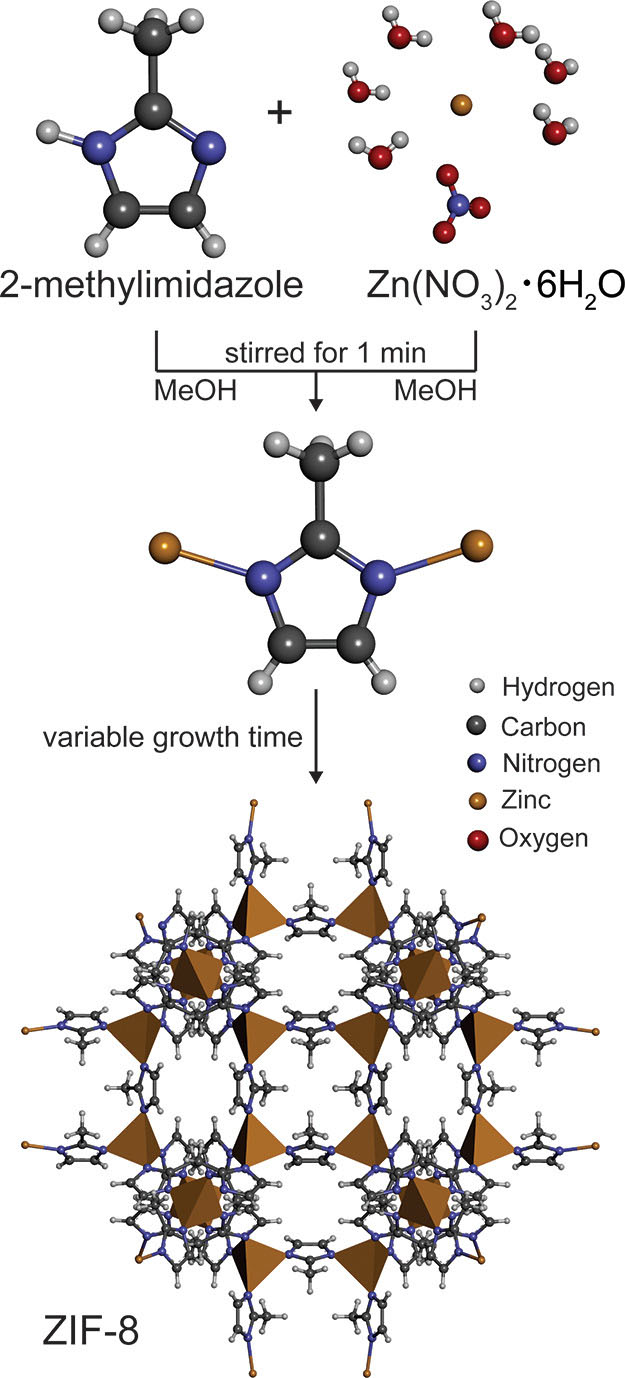

In contrast, little is known about defects in ZIF-8, a widely used MOF. In new work (ACS Applied Nano Materials, "Defect Engineering in Metal−Organic Framework Nanocrystals: Implications for Mechanical Properties and Performance"), researchers explore how defects transform during crystallization of ZIF-8, and elucidate their impact on the mechanical properties of the material.

|

|

| Schematic of the synthesis route of ZIF-8. (Reprinted with permission by American Chemical Society)

|

|

First, they tracked the transformation of defects in ZIF-8 by locally probing nano- and microcrystals at different stages (at 1, 3 and 60 minues) during crystal growth with s-SNOM.

|

|

What the team found was that with prolonged crystallization, or the ripening of the nanocrystals, defects gradually vanish, and the final growth stage is reached after 60 minutes. Perhaps the most significant implication of this defect evolution – it is even more striking than observing the defect itself – consists of a change of the mechanical properties: not only is the structural stiffness significantly lower in the presence of defects, but it also exhibits a higher local anisotropy.

|

|

The experimental evidence was corroborated by ab initio density functional theory (DFT) calculations through a comparison between ZIF-8 ideal and defective model structures.

|

|

The authors conclude by pointing out that knowledge of how defects affect the nanoscale mechanical behavior of ZIF-8 is key to targeted applications in catalysis, sensing, and gas capture, where not only is mechanical stability required but also defect engineering could further improve the material's performance.

|

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC