| May 10, 2019 | |

Superlubricity and nanotechnology |

|

| (Nanowerk Spotlight) Friction is the name given to the force that resists the initiation of sliding motion between two surfaces; it is all around us and it occurs at all length scales. In simple terms: friction is a force that slows things down. | |

| In many cases, it is exploited to improve our life (you couldn't walk, drive or even write if there was no friction at all); but on the other hand, a reduction of friction is required to reduce mechanical energy dissipation and wear. | |

| The reduction of friction is particularly critical for energy conservation where friction directly translates in a loss of efficiency and therefor higher use of energy for a particular task. About 1/3 of the world’s primary energy is dissipated in mechanical friction and 80% of machinery components' failure is caused by wear. Friction and wear are also bottlenecks for micro-/nano-mechanical systems (MEMS and NEMS) featured with sliding components. | |

| In Nature, there are no completely frictionless environments: even in deep space, tiny particles may interact and cause friction. Friction processes can be observed on all scales and dimensions. | |

| This is one reason why you can't have a perpetuum mobile, i.e. a motion that continues indefinitely without any external source of energy, as long as there is any friction. | |

|

|

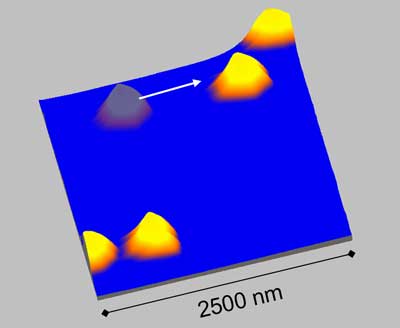

| Pushing Antimony. Some nanoscale metallic islands skate across a graphite surface with no friction, while others require a constant shove. The difference may arise when a few impurity atoms get stuck between the island and the surface below, adding new support to a microscopic theory explaining friction. (read more: New insight into the origins of friction) | |

| However, there is a very special case where friction almost vanishes between two surfaces. This is a phenomenon, known as superlubricity, in which surfaces simply slide over each other with barely any resistance (a state that is called near-zero friction). | |

| To date, however, most of the superlubricity observed experimentally has been realized only at the nanoscale and under extreme conditions like high vacuum or by using repulsive van der Waals forces. It therefore isn't really suitable for real world applications yet. | |

| The difficulty of achieving superlubricity in mechanical systems is due to the very complex physical, chemical, and mechanical interactions that occur simultaneously at the sliding interfaces of these systems. | |

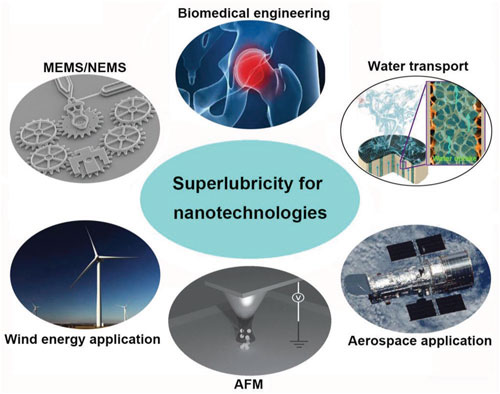

| Achieving near-zero friction in commercial and industrial applications will be game-changing from tiny microelectromechanical systems that will never wear out, to oil-free bearings in industrial equipment, to much more efficient engines and giant wind turbines scavenging energy even in low wind conditions. Superlubricity offers promising solutions to overcome lubrication challenges in various areas of nanotechnology including micro/nano-electromechanical systems (MEMS/NEMS), water transport control, biomedical engineering, atomic force microscopy (AFM), aerospace and wind energy applications, as well as other electronic devices. It is one of the most promising properties of functional nanomaterials for energy saving applications. | |

|

|

| Superlubricity offers solutions to lubrication challenges faced in various nanotechnologies including biomedical engineering, water transport, AFM, MEMS/NEMS, wind energy and aerospace applications. (Reprinted with permission from Wiley-VCH Verlag) | |

| For example, conductive AFM is one of the most effective instruments to characterize electrical properties of materials at the nanoscale. However, a critical challenge associated with this characterization technique is the low reliability of AFM tips during high-current testing, which is related to rapid wear by the friction of tip-sample interfaces. Therefore, superlubricity at the tip-sample interfaces is a promising way to avoid tip wear for reliable nanoscaled electrical characterization. | |

| Recent advances in two-dimensional (2D) materials, such as graphene, (but also hexagonal boron nitride, molybdenum disulfide, and other 2D materials) have excited the tribology community because the excellent tribological properties of these materials lower friction to superlubric regimes. This opens the real possibility of creating atomically thin solid lubricants. | |

| A recent review (Advanced Functional Materials, "Nanomaterials in Superlubricity") provides a status of the progress achieved to date in using nanomaterials for achieving superlubricity. | |

| The authors beging with a brief introduction of the role and use of nanostructured materials in superlubricity and their potential applications. Then they discuss in detail experimental and simulation works on the different spatial structures of nanomaterials associated with size effects ranging from 0D to 3D nanostructures. They conclude with perspectives on the challenges and future directions for developing nanomaterials in the field of superlubricity. | |

| The review is structured in major sections around the dimensionality of nanomaterials – 0D, 1D, 2D and 2D. Each section discusses recent achievements for both solid and liquid superlubricity for this class of nanomaterials. | |

| (Definition: The classification in 0D, 1D, 2D, and 3D nanomaterials is based on the number of dimensions of a material, which are outside the nanoscale (<100 nm) range. Accordingly, in zero-dimensional (0D) nanomaterials all the dimensions are measured within the nanoscale (no dimensions are larger than 100 nm). Most commonly, 0D nanomaterials are nanoparticles. In one-dimensional (1D) nanomaterials, one dimension is outside the nanoscale. This class includes nanotubes, nanorods, and nanowires. In two-dimensional (2D) nanomaterials, two dimensions are outside the nanoscale. This class exhibits plate-like shapes and includes graphene, nanofilms, nanolayers, and nanocoatings. Three-dimensional (3D) nanomaterials are materials that are not confined to the nanoscale in any dimension. This class can contain bulk powders, dispersions of nanoparticles, bundles of nanowires, and nanotubes as well as multi-nanolayers.) | |

| The authors conclude that an explosive progress of superlubricity has been achieved in nanomaterials: | |

| 0D nanomaterials including C60, carbon quantum dots, Sb nanoparticles, nanodiamonds, nanoscrolls and onion-like carbon effectively promote the superlubric state due to their size effects that can result in the transition from commensurate contact to incommensurate contact within the local interface. | |

| Carbon nanotubes have proven to be one effective type of 1D nanomaterials for enhanced superlow friction at both the nanoscale and the macroscale. With large internal stiffness from C–C bonding and low interfacial stiffness caused by weak interplane interactions, these 1D carbon-based nanostructures would be good candidates for the implementation of practical superlubric applications. | |

| The intrinsic lubricating property of 2D nanomaterials including graphene nanoflakes, MoS2, and graphene-based heterostructures enabled them of desired low-friction behaviors. | |

| The development of novel 3D-nanostructured materials including C60-modified graphene oxide films and graphitic-like amorphous carbon/MoS2 composite coatings opened up a new path to the design of nanostructures with superlubricity at high stress and strain levels. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|