| May 10, 2022 | |

Combining 3D printing and self-assembly to fabricate the world's lightest material |

|

| (Nanowerk Spotlight) In nature, wood, shells, and other structural materials are lightweight, strong, and tough. These multiscale structures enable a series of outstanding performances using a limited number of constituent materials with ordinary properties. | |

| While natural creatures are able to fabricate these complex structures through bio-controlled assembly, material engineers and scientists have found it difficult to develop artificial materials with multiscale structures expanding from nano- to macroscale. | |

| Significantly, these natural materials are made at the ambient temperature in the local environment – not at the high temperatures at which human-made structural materials are generally processed. | |

| Over the past decade, researchers have developed additive manufacturing techniques that produce precisely tailored lattice structures from the micro- to the macroscale, resulting in amazing materials. Examples are ultralight metals that are 100 times lighter than styrofoam, ultralight and ultrastiff metamaterials that could be fabricated from a variety of materials, such as metals or polymers, and that may set new records for stiffness for a given weight. Researchers have also developed a bioinspired approach to 3D print recyclable liquid crystal polymers using conventional desktop printers that outperform state-of-the-art printed polymers and even rival the highest performance lightweight materials. | |

| "Significant progress has been made in the formation of such 3D printed structures but structural control from the nano- to the macroscale is still a major challenge due to the limited ability of existing manufacturing methods to control multi-scale hierarchical structures with high complexity," Ling Qiu, an Associate Professor at Tsinghua Berkeley Shenzhen Institute, tells Nanowerk. "For example, even for the most advanced and delicate nanomanufacturing techniques like two-photon lithography, the length-scale range for controllable structure is limited to hundreds of nanometers to millimeters, leaving aside the significant time cost." | |

| Based on their knowledge of 2D materials chemistry, Qiu, Prof. Hui-Ming Cheng, and their fellow scientists at the Shenzhen Geim Graphene Center realized that graphene – which possesses a variety of interesting properties like ultralow density, high compressibility, specific surface area, and electrical conductivity – could be an ideal building block to generate versatile 3D networks from controlled self-assembly. | |

|

|

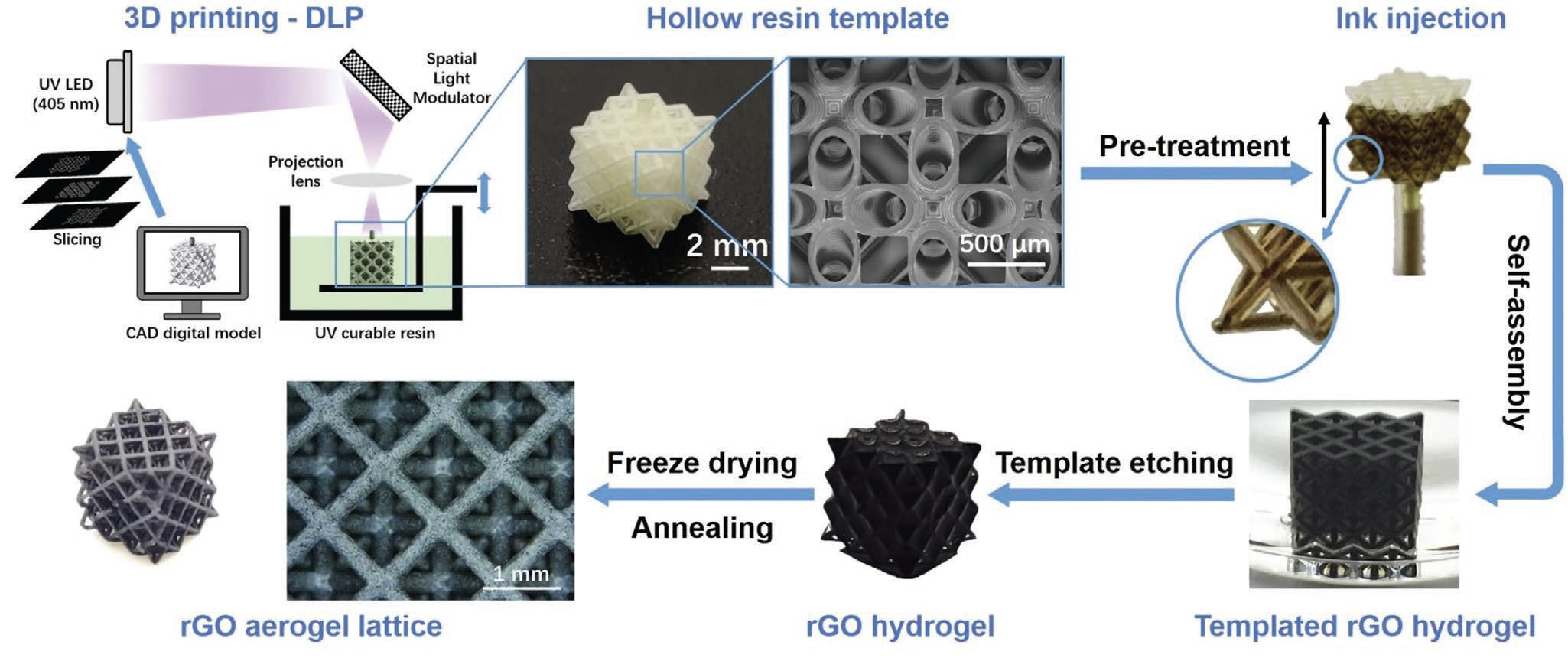

| Fabrication process of multiscale graphene structures and structure demonstration of micro and macro scale. a) Schematic of the fabrication process. Following the arrows: a designed resin template was sliced from 3D digital model into 2D images and then printed by the DLP method. After oxygen plasma treatment to modify its hydrophilicity to allow injection with ink, the template hollow struts were filled using a syringe pump. An rGO hydrogel was formed by self-assembly inside the template, and the template was chemically etched away to obtain a pure rGO hydrogel after rinsing with DI water. After freeze-drying and annealing, a freestanding rGO aerogel was obtained. (Reprinted with permission by Wiley-VCH Verlag) | |

| Meanwhile, the rapidly advancing 3D printing techniques (if you want to read up on 3D printing in general, check out our guides on the best 3D printers for beginners and professionals as well as the best repositories of free 3D printing models and design files) offer unprecedented structural design freedom and 3D-printing simple nanostructures with graphene has already been demonstrated. However, it has remained challenging to fabricate 3D pure graphene structures with high structural complexity. | |

| "Therefore we would like to combine the strength of the fabrication method and material features, to preserve the pristine properties of functional materials (like the low density and large deformability for graphene structures) and to study their structure-dependence," Qiu explains the background for the team's latest work, reported in Advanced Functional Materials ("3D Printed Template-Directed Assembly of Multiscale Graphene Structures"). | |

| In this work, the team used graphene as the model building block, just like a Lego® piece. By using a combination of 3D printed template and self-assembly technique, the graphene 'Lego pieces' can be assembled into a programmed structure from nano- to macro-scale. | |

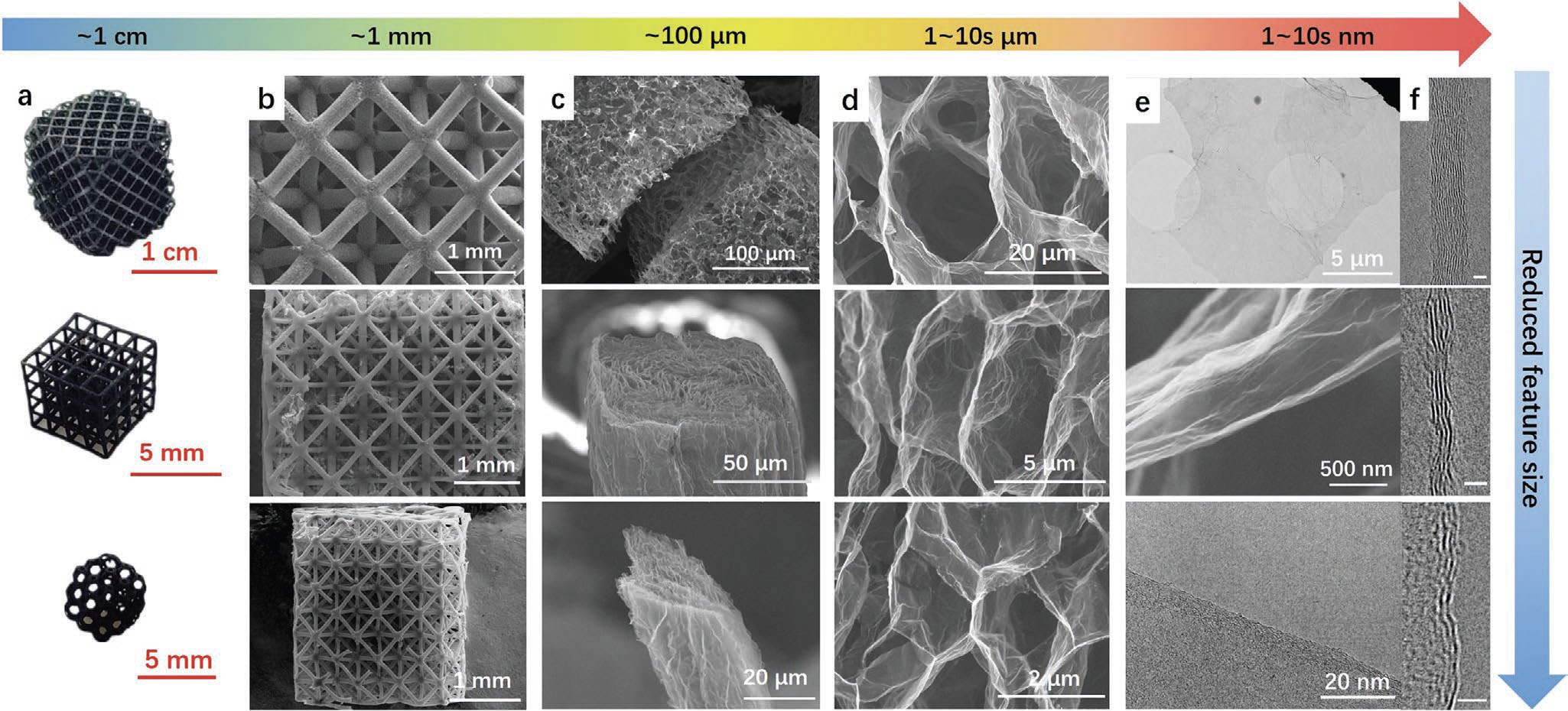

| This technique allows the fabrication of materials with complex Lego-like models with tailorable feature size crossing a record seven orders of magnitude – from nanometers to centimeters. This resulted in the fabrication of graphene structures with tunable mechanical properties, from super rigid (modules one order of magnitude higher than other ultralight materials) to superelastic (able to recover from extreme 95% compression). | |

|

|

| Structure of multiscale graphene structures with controllable features across seven orders of magnitude in size. a) Optical images of multiscale graphene structures with different sizes in the ∼1 cm scale. b-d) SEM images showing structural hierarchy from 1 mm to tens of micrometers with highly tunable feature sizes. e) TEM images showing flakes of multiscale graphene structures with different sizes and thicknesses (scale bar of the right image: 2 nm). (Reprinted with permission by Wiley-VCH Verlag) | |

| The fascinating result is the world's lightest material with a density of 0.08 mg/cm3 – which is 15 times lower than the density of air. | |

| This research not only provides a facile approach to fabricate programmed graphene structures, but reveals the possibility of customizing its properties by rational design of multi-length scale structure towards a plethora of applications. | |

| "Our work provides a potentially universal method to create diverse 3D structures with high resolution, multi-scale design using different functional nanomaterials, thereby expanding the fabrication capabilities of existing 3D printing techniques," Jingzhuo Zhou, the paper's first author, points out. | |

| Although there have been several reports about the macroscopic structures derived from 3D printed templates, they mainly focused on the compositions of the injected materials (e.g field-responses of magnetic fluid) with the 3D printed polymer (or the remaining carbonized skeleton) as structural support. | |

| In contrast, the novelty of this work lies in the controllable self-assembly of graphene sheets inside the template, which enables much higher precision control of the structure than previous works with pure functional materials (template completely removed). | |

| In general, the mechanical strength (such as Young's modulus) of bulk materials degrades exponentially with decreasing bulk density, which limits the development and application of lightweight materials. But thanks to this novel fabrication technique, the fabrication of structures with record low density and record high modulus becomes possible. | |

|

|

| Ultralight graphene lattice floats on a feather. (Image courtesy of the researchers) | |

| The graphene structures demonstrated in this work can achieve ultralow density (mainly in the range of 0.1 to 1 mg/cm3) and corresponding ultrahigh stiffness (Young's modulus is an order of magnitude higher than that of reported materials with the same density). | |

| The team also used their graphene structures for the fabrication of ceramics. Generally, fabricating multi-level ceramic structures is difficult: the microstructure cannot be easily controlled and the macrostructure is hard to process. By using the novel graphene structures as templates, combined with deposition techniques, the researchers showed that it is possible to obtain pure ceramic structures that replicate the graphene hierarchical structures after air sintering. | |

| The 3D printed graphene structure is picked up by a feather. (Video courtesy of the researchers) | |

| "Our 3D printed template-directed assembly method can be applied to other polymers or nanoparticle colloidal dispersion systems, expanding the range of materials that can be fabricated into elaborately tailored architectures," Qiu notes. "The realization of high design freedom of multi-length scale structure provides a materials platform for systematic research on structure-property relationships. Last but not least, the nearly unlimited structural design freedom for a range of potential materials offers virtually infinite possibilities for the creation, optimization, and customization of application-oriented architectures." | |

| For example, this method could provide a potential universal solution to the manufacture of 3D electrodes in energy storage devices with customized fine structures for easy electrolyte permeation and fast ion diffusion, thus enabling extraordinary areal energy density and power density. | |

| In ACS Nano ("3D Printed Template-Assisted Assembly of Additive-Free Ti3C2Tx MXene Microlattices with Customized Structures toward High Areal Capacitance"), the team also reported that they successfully obtained pure MXene architectures with a comparable level of structural complexity as in this work. | |

| With rational design of the structure, the fabricated MXene architectures can obtain high areal capacitance, areal energy density and charge retention (87%) with a high mass loading. By tuning tortuosity, the MXene architectures can achieve high rate performance or capacity performance based on customized requirements. | |

| This means that, in principle, this method is applicable to any nanomaterial that can be assembled from a stable suspension into a self-supported structure. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|