| Jul 11, 2022 | |

Engineering living hydrogels |

|

| (Nanowerk Spotlight) Hydrogels are fascinating natural or synthetic polymer materials that exhibit very versatile chemistries and physical or biological properties. They are 3D networks of either physically or chemically cross-linked polymers that resemble organic tissues and that can hold large amounts of water within their interlocked molecular network (check out our primer on hydrogels. | |

| Inspired by living biological systems, which can sense, process information, and actuate in response to changing environmental conditions, researchers are exploring engineered living hydrogels. The convergence of engineering, biology, and materials science over the past 20 years is providing unprecedented opportunities to integrate living cells (e.g., microbes or microbial consortia) into these hydrogels. This integration yields engineered living hydrogels with the capabilities of self-replication, self-regulation, and environmental responsiveness – a new class of living systems. | |

| One such example are 3D-printed living minifactories – bacteria-containing hydrogel ink that makes it possible to print mini biochemical factories with certain properties, depending on which species of bacteria the scientists put in the ink. Another example are living sensors: a tough, stretchy, biocompatible sheet of hydrogel injected with live cells that are genetically programmed to light up in the presence of certain chemicals. | |

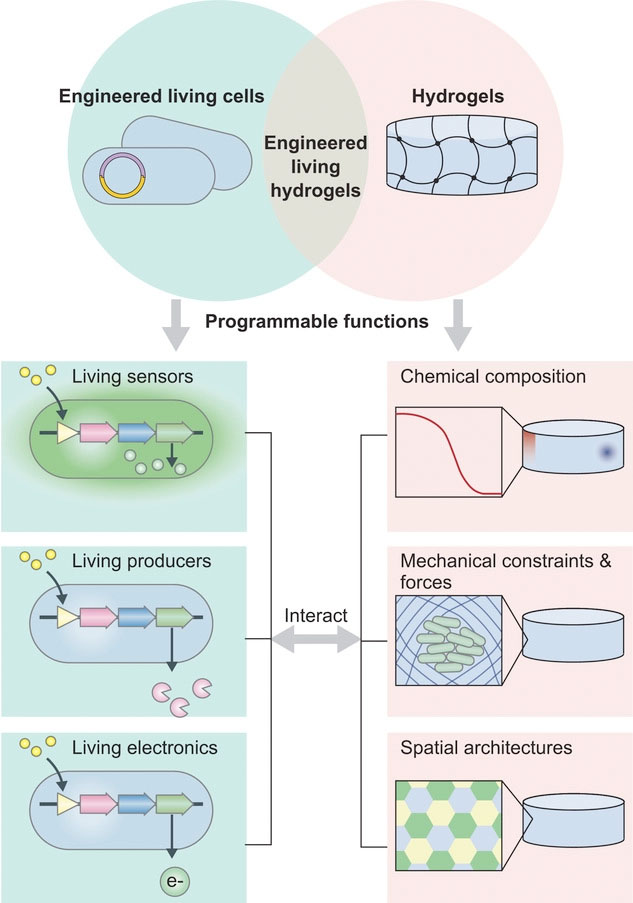

| Intriguingly, both components in engineered living hydrogels are programmable for specific goals: The living cells can be engineered with diverse capabilities, including sensing, chemical production, and electricity generation; whereas the hydrogels can be fabricated with various functions to create chemical gradients, mechanical confinement, and spatial distribution for the living cells. | |

| Since the 2000s, the development of engineered living hydrogels has been facilitated by technological advances in genetic engineering, metabolic engineering, and fabrication tools. Advances in the fundamental understanding of material chemistry, polymer physics, and cell biology have also contributed to research on engineered living hydrogels. | |

|

|

| The convergence of engineered living cells and hydrogels gives rise to the technology of engineered living hydrogels. In the engineered living hydrogels, cells and hydrogels interact with each other. The living cells can be programmed with diverse functions, including sensing, chemical production, and electricity generation. The hydrogels can also be programmed with various functions, which create chemical gradients, mechanical confinement and forces, and spatial distribution for the engineered living cells. (Reprinted with permission by Wiley-VCH Verlag) | |

| A recent article in Advanced Materials ("Engineered Living Hydrogels") discusses two pressing questions regarding engineered living hydrogels: how do hydrogel matrices alter cell behaviors, and how do living cells affect the matrix properties? It then reviews the ways that the engineered living hydrogels interact with the environment, focusing on the applications of sensing, treatment, and energy conversion that are enabled by engineered living hydrogels. | |

| Depending on the configuration of the hydrogel matrix, engineered living hydrogels can be classified into three types: cell-generated hydrogels encapsulating cells, synthetic hydrogels encapsulating cells, and hydrogel chambers containing cells. In cell-generated and synthetic hydrogels, living microbial cells are dispersed throughout bulk hydrogel structures, whereas in hydrogel chambers, the cells are contained in a hollow space inside. | |

| The features of hydrogel matrices (e.g., their chemical composition, microscale structure, and mechanical properties) define the local environment of microbial cells and affect cell dynamics and further determine whether the cells divide, move, secrete chemicals, exert forces, or express extracellular polymers. | |

| Vice versa, living cells also influence the hydrogels they are embedded in. In engineered living hydrogels, living cells can generate, regenerate, reinforce, or degrade hydrogel materials and also form patterns on hydrogel surfaces. In addition, living cells, equipped with natural or synthetic genetic circuits, can be designed to tune the hydrogel properties in response to environmental variations; the ability to interact with their surroundings considerably expands the applications of hydrogels. | |

| The ability of researchers to engineer microbial cells to produce biopolymers and generate hydrogel materials depends on their understanding of biopolymer synthesis and secretion pathways. They can then modify existing pathways by making reactions more efficient or removing undesirable side reactions. Strategies such as directed evolution and environmental selection have been used to optimize production. As a bottom-up approach, genetic engineering can be used for versatile biopolymer production. | |

Applications of engineered living hydrogels |

|

| Engineered living hydrogel can interact with external environments, and these interactions enable versatile applications in industry and biomedicine. This interaction facilitates their use as sensors for health or environmental conditions, therapies for diseases, treatments for environmental pollution, actuators for mechanical energy conversion, and batteries for electrical energy conversion. | |

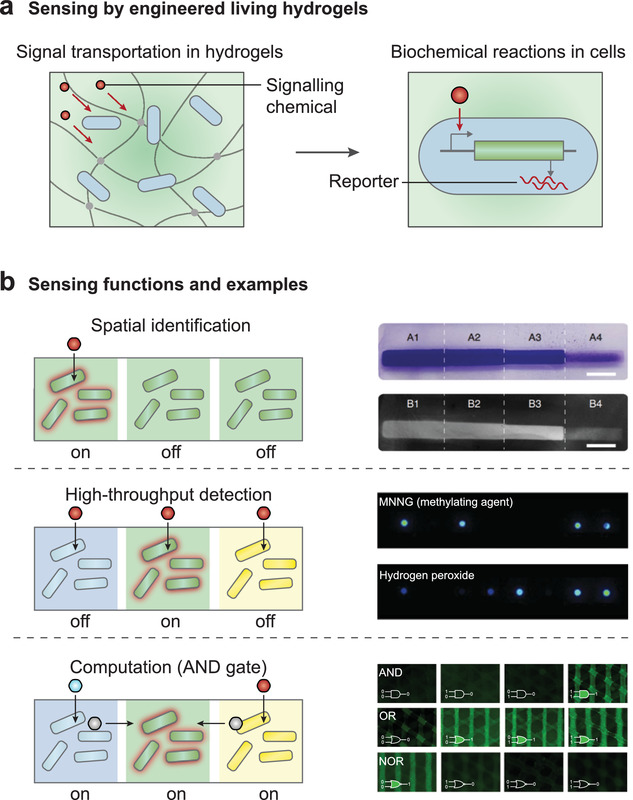

| In a typical sensing process, external signals (e.g., heat, light or chemicals) are first delivered through the hydrogel matrix to the living microbial cells within it. Upon receiving the signals, cells report on these external signals through natural or engineered genetic modules. The sensing outputs are usually fluorescence, bioluminescence, or conductivity in cells, and the collective cell expression in the hydrogel matrix can be further quantified in terms of light intensity or electrical resistance. | |

|

|

| Engineered living hydrogels can sense environmental signals. a) Sensing by engineered living hydrogels in two coupled steps: signal transportation in hydrogels and biochemical reactions in cells. b) Sensing functions and examples by engineered living hydrogels. b, top) Spatial identification of light intensity. b, middle) High-throughput detection of toxic chemicals. b, bottom) Logic gate sensing and computation. (Reprinted with permission by Wiley-VCH Verlag) | |

| Engineered living hydrogels can produce a wide range of soluble biomolecules, including metabolites, antibiotics, and enzymes for disease treatment and environmental remediation. Biomolecules produced by living microbial cells can be transported through the hydrogel matrix and delivered to the environment. For example, antimicrobial agents (e.g., penicillin) and extracellular proteins can be readily released from microorganism-containing hydrogels; these molecules can be used to treat diseases or to reduce environmental pollution (with pollutant-degrading enzymes). | |

| Toxin and pollutants in the environment can also be absorbed by the hydrogel matrix and metabolized by the cells. For example, genetically engineered E. coli immobilized in alginate hydrogels can effectively remove urea and ammonia in uremic rats with renal failure. Ralstonia metallidurans in alginate hydrogels can convert the toxic Hg(II) to nontoxic Hg(0). The phenol degradation capability of Pseudomonas putida has been demonstrated in a 3D-printed hydrogel matrix. Thus, engineered living hydrogels can help break down body wastes, disease by-products and environmental hazards. | |

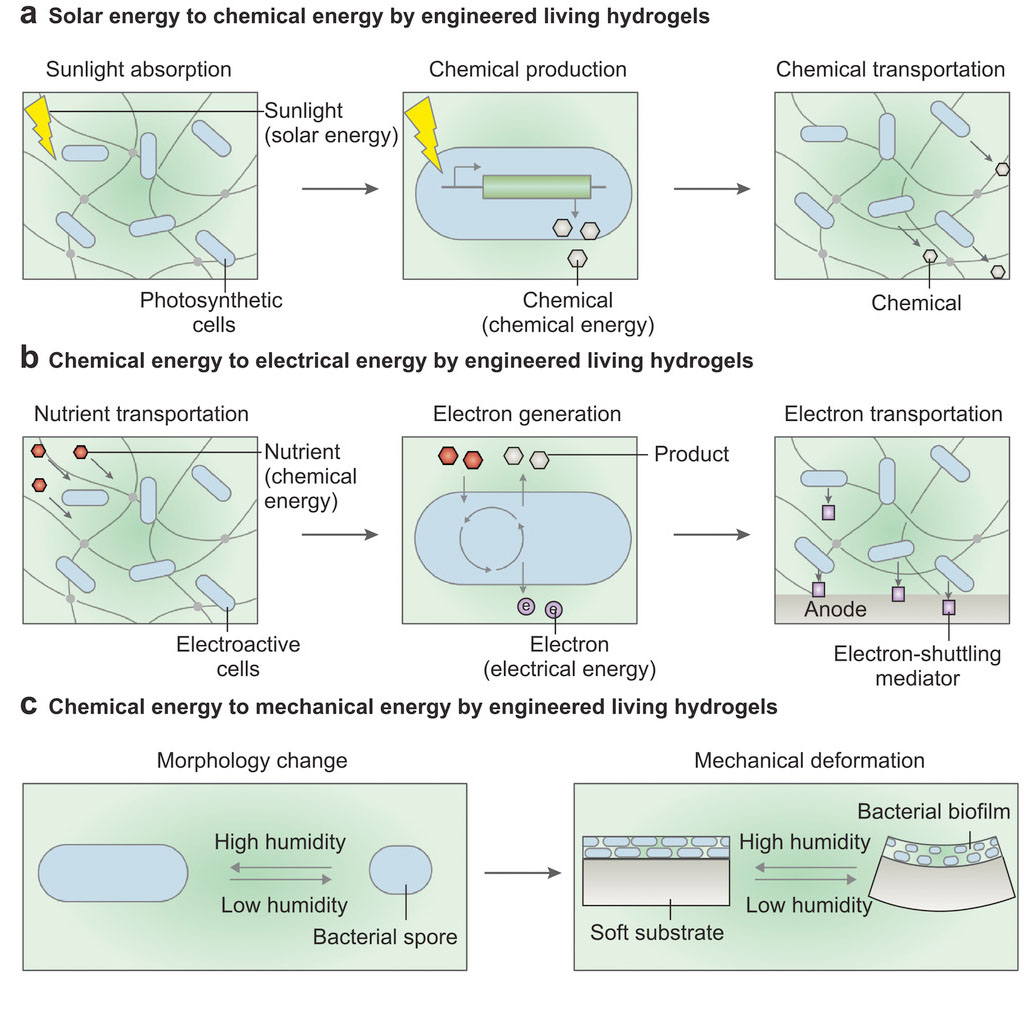

| As a result of their metabolic activities, microbial cells can generate chemical, electrical, and mechanical energy. By converting one type of energy into another, engineered living hydrogels can provide an alternative and sustainable way of producing energy and fuel. | |

|

|

| Engineered living hydrogels that can generate chemical, electrical, or mechanical energy. a) Chemical energy is generated by engineered living hydrogels in three coupled steps: sunlight absorption in hydrogels, chemical production in cells, and molecule transportation in hydrogels. b) Electrical energy is generated by engineered living hydrogels in three coupled steps: nutrient transportation in hydrogels, nutrient consumption and electron generation in cells, and electron transfer in hydrogels. c) Mechanical energy is generated by engineered living hydrogels in two coupled steps: morphological change of the cells and mechanical deformation of hydrogels. (Reprinted with permission by Wiley-VCH Verlag) | |

| For instance, photosynthetic microalgae or cyanobacteria incorporated into the hydrogels can convert light energy into chemical energy through cellular respiration. Photosynthesis allows sustainable production of metabolites (e.g., glucose, hydrogen) and high-value chemical compounds such as biofuels and pharmaceuticals. | |

| One of the biggest hurdles for translating research on engineered living hydrogels into biomedical, industrial, and environmental applications is that the undefined, changing environment surrounding the engineered living hydrogel can lead to high variability in its behavior. | |

| Here are two examples: When engineered living hydrogels are intended to be deployed in environments that are nutrient-deficient (e.g., tap water) or toxic (e.g., wastewater), the hydrogel matrices need to be designed to support the long-term functioning of microbial cells. Engineered living hydrogels that will be used in wastewater can be programmed for nutrient diffusion and toxin sequestration. In this case, hydrogel chemistry and microfabrication can be applied so that the transport of these molecules is controllable. | |

| In the example of topical drug delivery, localized environmental remediation, and other functions adapted to particular environments, hydrogel matrices can be engineered through polymer physics and lab-on-a-chip technology to provide precise spatiotemporal modulation of biochemical and biophysical cues and to accommodate living cells to dynamic environments. | |

| At a more fundamental level, the functionality of engineered living hydrogels can be expanded by genetically engineering the behavior of living cells, for example, by tailoring responses to specific stimuli or enhancing recombinant protein yields. An enlarged genetic toolkit could be used to engineer more microbial species with versatile functions, for example, gut microbes that can treat GI disorders or soil bacteria that can promote plant growth. | |

| The authors conclude their review by stressing that the required accelerated testing and application of engineered living hydrogels in the real world will require collaboration among engineers, biologists, clinicians, regulatory agencies, and others. Once the associated ethical, legal, and social implications have been thoroughly explored, engineered living hydrogels can be built to address a variety of societal needs, ranging from health management to environmental remediation to infrastructure construction. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|