| Apr 09, 2024 | |

Innovative plasma polymer nanoparticles for bioactivating inert materials |

|

| (Nanowerk Spotlight) The development of effective methods for functionalizing materials has been a long-standing challenge in the biomedical field. Many porous scaffolds commonly used as biomaterials, such as hydrogels, electrospun polymers, and 3D-printed metals, are inherently inert and lack the essential biological cues required to promote desired cellular responses. While conventional surface modification techniques like plasma treatments have been widely employed to address this issue, they come with significant limitations that have hindered their broader adoption. | |

| Plasma-based approaches rely on exposing materials to a reactive environment containing energetic ions, electrons, radicals, and photons generated from gas precursors. These interactions can induce physical and chemical changes to the material surface, modulating properties such as topography, chemistry, charge, and wettability. However, the need for vacuum conditions and direct contact with reactive media renders plasma treatments unsuitable for substrates that demand aqueous environments, such as proteins and hydrogels. Furthermore, the complexity of treating intricate geometries often necessitates extensive customization for each material and shape. | |

| Over the years, researchers have explored alternative strategies to overcome these constraints. Plasma-assisted deposition of thin film coatings, known as plasma polymer coatings (PPC), has emerged as a promising approach for modifying inert substrates like metals and ceramics. These coatings are formed by polymerizing reactive organic or organosilicon monomers under mild plasma conditions. While PPC have demonstrated potential in enhancing surface hydrophilicity, immobilizing biomolecules, and improving biocompatibility, they still require direct exposure to a plasma environment and are limited by line-of-sight deposition. | |

|

|

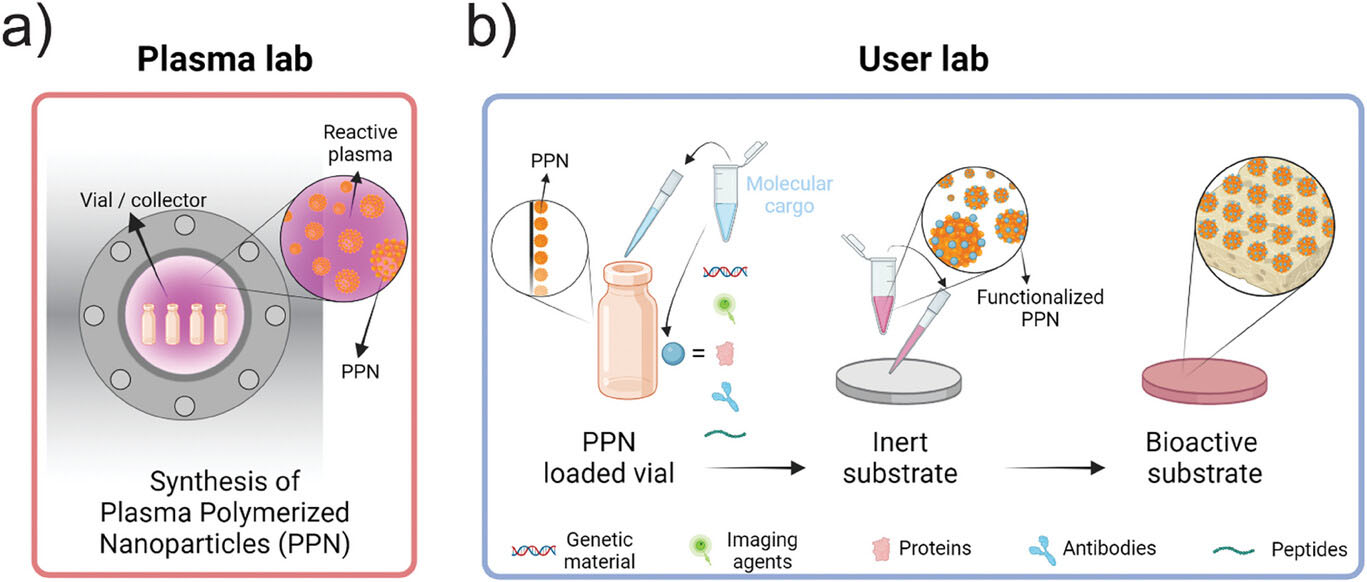

| a) Schematic depicting one-step synthesis of plasma polymerized nanoparticles (PPN) in the plasma lab. The process is based on radiofrequency-driven plasma polymerization of a reactive mixture of acetylene, nitrogen, and argon to produce PPN in the plasma bulk which is concentrated and collected in vials. b) Streamlined bioactivation of inert substrates using PPN. The vials containing PPN can be sent from the plasma lab directly to the final user’s lab for an “on-demand” functionalization process without requiring direct access to a plasma device. A wide range of molecular cargo can be immobilized on PPN in aqueous solution in a one-step process. Functionalized PPN is subsequently incubated with substrates also in aqueous solution and robustly attached to the material surface. (Reprinted from doi:10.1002/adma.202311313, CC BY) | |

| In a recent study published in Advanced Materials ("On-Demand Bioactivation of Inert Materials With Plasma-Polymerized Nanoparticles"), a team of researchers from the University of Sydney propose a groundbreaking solution to these long-standing challenges. They introduce plasma polymer nanoparticles (PPN) as a versatile functionalization tool that can bioactivate inert materials in an aqueous solution, without the need for direct plasma exposure or vacuum conditions. | |

| PPN are discrete spherical nanoparticles synthesized in a plasma polymerization system using similar process conditions as PPC. However, unlike PPC which form uniform coatings on flat surfaces, PPN are collected from the plasma bulk and can be resuspended in aqueous solutions. This unique feature allows for the functionalization of a wide range of materials, including those previously excluded from traditional plasma treatments. | |

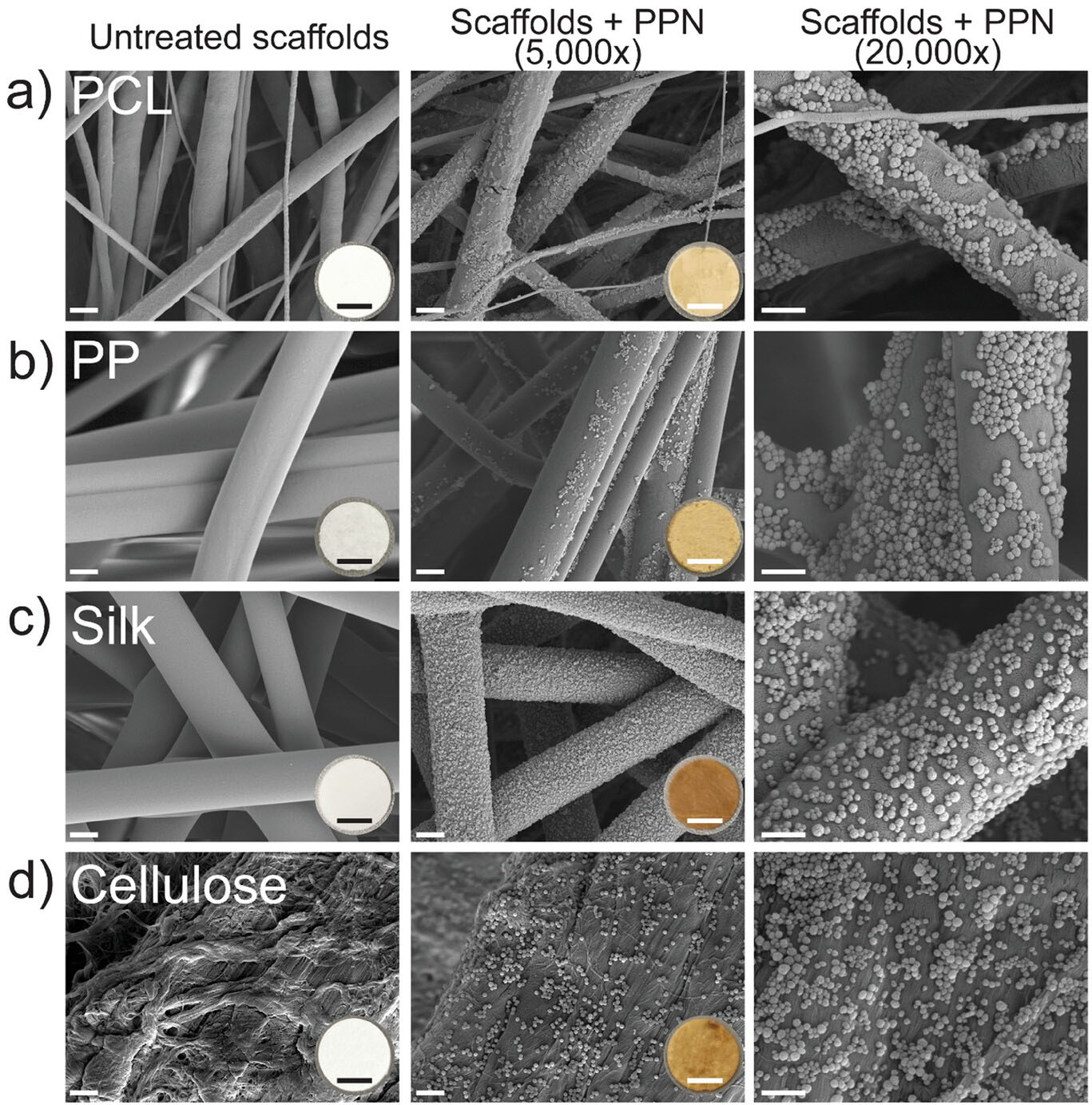

| The researchers demonstrate the robust immobilization of PPN on various substrates, such as synthetic polymers, proteins, and complex hydrogel structures. Incubating these materials in PPN solutions leads to significant adsorption of the nanoparticles onto the substrate surface, resulting in enhanced surface hydrophilicity and changes in chemical composition. Remarkably, the adsorbed PPN remain stably bound even under stringent washing conditions, suggesting a strong interaction with the substrates. | |

| One of the key advantages of PPN is their ability to carry and immobilize molecular cargo, such as bioactive peptides, onto inert scaffolds. The study shows that functionalizing electrospun polycaprolactone (PCL) scaffolds with PPN loaded with arginylglycylaspartic acid (RGD) peptides significantly enhances cell attachment, spreading, and proliferation compared to bare PCL or passively adsorbed RGD. This bioactivation strategy is also successfully applied to 3D printed polyethylene glycol diacrylate (PEGDA) hydrogel scaffolds, which are notoriously difficult to functionalize due to their incompatibility with plasma treatments. | |

|

|

| Functionalized a) electrospun polycaprolactone (PCL), b) polypropylene (PP) fibers, electrospun silk and cellulose (filter paper) substrates with pristine plasma polymerized nanoparticles (PPN). Panels show scanning electron microscopy (SEM) and photographs (insets) of substrates before (pristine) and after functionalization with PPN (at a nanoparticle concentration of 1010 PPN mL−1). Scale bars = 2 µm for untreated and PPN functionalized scaffolds, 400 nm in zoomed images, and 3 mm in insets. (Reprinted from doi:10.1002/adma.202311313, CC BY) | |

| The implications of this work extend far beyond the specific materials and cell types investigated. The ability to functionalize complex geometries and porous structures in aqueous environments opens up new possibilities for a wide range of biomedical applications. From tissue engineering scaffolds to drug delivery systems and medical devices, PPN offer a versatile and accessible tool for imparting bioactivity and tailoring surface properties. | |

| Moreover, the off-the-shelf nature of PPN allows for their production and storage in a dry state, ready to be resuspended and functionalized as needed. This streamlined approach eliminates the need for direct access to specialized plasma facilities, making it feasible for researchers in various biomedical fields to adopt this technology. | |

| While further research is needed to fully understand the long-term stability, degradation profile, and in vivo behavior of PPN-functionalized materials, the initial results presented in this study are highly promising. The development of PPN as a robust and versatile functionalization tool has the potential to revolutionize the way we design and engineer biomaterials, enabling the creation of highly bioactive and tailored substrates for a wide range of biomedical applications. | |

| As the field of biomaterials continues to evolve, the ability to effectively functionalize inert substrates will be crucial for developing advanced solutions that can modulate cellular behavior, promote tissue regeneration, and enhance biointegration. Plasma polymer nanoparticles represent a significant step forward in this direction, offering a powerful and accessible tool for overcoming the limitations of conventional plasma treatments and unlocking new possibilities in biomedical research and applications. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|