Understanding Bottom-up Nanotechnology and Its Impact on Future Innovations

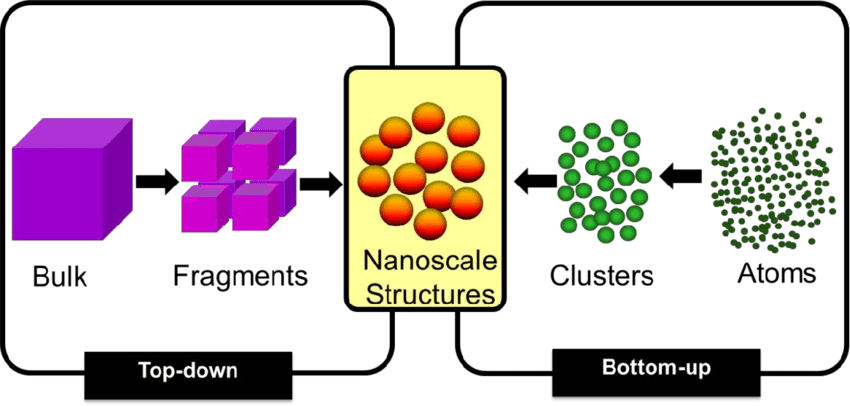

Definition: Bottom-up nanotechnology is an innovative approach to constructing nanostructures that differ significantly from traditional top-down manufacturing methods. Instead of carving out or etching away from larger blocks of materials to achieve nanoscale dimensions, bottom-up nanotechnology builds materials and devices atom by atom or molecule by molecule. This method harnesses the principles of chemistry and physics to organize basic units into complex structures with precision at the nanometer scale.

Fundamental Principles and Methodologies

At the heart of bottom-up nanotechnology lies a process driven by thermodynamics and kinetics, rather than the deterministic approaches characteristic of top-down methods. This fundamental difference allows for the assembly of nanoscale structures in a more natural and energy-efficient manner.

Bottom-up techniques do not require the expensive and sophisticated tooling often associated with top-down nanofabrication, making them more cost-effective and scalable. These processes leverage the forces of attraction and repulsion at the molecular level, guiding the self-organization of atoms and molecules into desired structures with minimal external intervention.

How Bottom-up Nanotechnology Works

The process starts at the molecular or atomic level, where materials are synthesized through chemical reactions that allow for the precise control of size, shape, and function. Techniques such as chemical vapor deposition, molecular beam epitaxy, and self-assembly are commonly used to engineer nanomaterials from the bottom up.

This approach enables the production of nanostructures with a high degree of order and uniformity, which is often challenging to achieve with top-down methods. By controlling the assembly process at the molecular level, scientists can create materials with unique optical, electrical, and mechanical properties.

Key Features of Bottom-up Nanotechnology

Bottom-up nanotechnology is characterized by several distinct advantages:

- Precision Engineering: Enables the precise control over the material's composition and structure at the nanoscale, leading to high-performance nanomaterials.

- Cost-Effectiveness: Potentially lower costs due to reduced waste and the ability to use less material for the same function.

- Versatility: Can be applied to a wide range of materials, including metals, semiconductors, and polymers, for various applications.

- Sustainability: Offers a greener approach to nanomanufacturing by minimizing energy consumption and waste production compared to top-down methods.

Limitations of Bottom-up Nanotechnology

Despite its advantages, there are challenges to bottom-up nanotechnology:

- Complexity of Control: Precisely controlling the self-assembly process at the nanoscale can be complex and requires a deep understanding of the interactions at play.

- Scalability Issues: Scaling up bottom-up approaches for industrial production remains a significant challenge, limiting the widespread adoption of this technology.

Applications of Bottom-up Nanotechnology

The practical applications of bottom-up nanotechnology are vast and varied, revolutionizing fields from medicine to electronics. For instance, dendrimers and other nanoscale carriers are being developed for targeted drug delivery systems, offering unprecedented precision in treating diseases at their source without affecting healthy tissues. In the realm of electronics, quantum dots synthesized through bottom-up processes are enhancing the brightness and color range of LED displays, making them more energy-efficient and vibrant.

Manufacturing breakthroughs have been achieved by applying bottom-up methods to produce quantum dots, carbon nanotubes, metallic nanowires, and plasmonically active particles in large quantities. These materials are essential for creating the next generation of electronic devices, photovoltaic cells, and medical diagnostic tools. The scalability of bottom-up fabrication means that these advanced materials can be produced efficiently, paving the way for their widespread adoption in various industries.

The unique capabilities of bottom-up nanotechnology have led to its application in several fields:

- Drug Delivery Systems: Utilizing dendrimers and liposomes, bottom-up nanotechnology enables the design of nanoparticles that can precisely target specific cells or tissues, improving the efficacy and reducing the side effects of treatments. For example, dendrimers are used to deliver cancer drugs directly to tumor cells, minimizing damage to healthy cells.

- Electronics: Quantum dots, created through bottom-up assembly, are used in light-emitting diodes (LEDs) and displays to produce vibrant colors and increase energy efficiency. These nanocrystals can be tuned to emit specific colors by adjusting their size, which is crucial for high-definition TVs and monitors.

- Energy Storage and Conversion: In the field of energy, bottom-up nanotechnology has led to the development of advanced materials for batteries and solar cells. Graphene, a single layer of carbon atoms arranged in a two-dimensional lattice, is synthesized through chemical vapor deposition to create batteries with significantly higher capacity and faster charging times than traditional ones.

- Environmental Remediation: Nanomaterials such as titanium dioxide nanoparticles are engineered for the detection and neutralization of pollutants. These nanoparticles can break down harmful chemicals in water when exposed to UV light, offering a potent tool for purifying water sources contaminated with industrial waste.

Diverse Approaches within Bottom-Up Nanotechnology

Bottom-up nanotechnology encompasses two primary methodologies: self-assembly and molecular assembly. Both strategies aim to construct complex nanostructures, but they differ in their mechanisms and inspirations.

- Self-Assembly: This process is inspired by natural phenomena, where molecular components automatically organize into ordered structures without external direction. Examples of self-assembly can be seen in biological systems, such as the folding of proteins and the organization of cellular membranes. These processes occur across different scales in nature, demonstrating the universal applicability of self-assembly principles.

- Molecular Assembly: Contrasting with the spontaneous nature of self-assembly, molecular assembly involves more deliberate and controlled efforts to build nanostructures. This approach is akin to a nanoscale factory line, where individual atoms and molecules are placed with precision to create complex devices and materials. Molecular assembly represents a more engineered approach to nanotechnology, holding the promise of fabricating advanced devices with functionalities designed from the ground up.

Innovative Applications: Bottom-Up Self-Assembly Based on DNA Nanotechnology

One of the most exciting advancements within bottom-up nanotechnology is the development of DNA-based self-assembly processes. DNA nanotechnology leverages the inherent properties of DNA molecules to design and construct precise nanostructures through self-assembly. This approach utilizes the specificity of base pairing, where complementary strands of DNA hybridize to form double helices, enabling the creation of complex, predictable, and highly functional nanostructures.

- Applications in Medicine and Technology: The implications of DNA nanotechnology are profound, particularly in medicine and biotechnology. For example, DNA nanostructures can be designed to carry therapeutic drugs to specific cells or tissues in the body, enhancing the efficacy and reducing the side effects of treatments. In diagnostics, DNA-based nanostructures offer highly sensitive platforms for the detection of biomarkers associated with various diseases.

- Challenges and Future Directions: While DNA nanotechnology represents a promising frontier in bottom-up assembly, challenges remain in terms of scalability and stability of the nanostructures under physiological conditions. Future research is focused on overcoming these hurdles, with the aim of translating DNA nanotechnology from the laboratory to practical applications in healthcare, electronics, and materials science.

The Future of Bottom-up Nanotechnology

The ongoing integration of bottom-up nanotechnology in these and other fields is expected to yield even more innovative solutions. As researchers continue to explore and harness the potential of constructing materials atom by atom, the scope of possible applications is set to expand, promising transformative advancements across science, medicine, and technology.

Further Reading

Nanomaterials, "Bottom-Up Self-Assembly Based on DNA Nanotechnology"

Advances in Colloid and Interface Science, "Advances in top???down and bottom???up surface nanofabrication: Techniques, applications & future prospects"

Advances in Colloid and Interface Science, "Synthesis of nanomaterials using various top-down and bottom-up approaches, influencing factors, advantages, and disadvantages: A review"