Nanosphere Colloidal Lithography: Self-Assembly for Nanostructure Fabrication

What is Nanosphere Colloidal Lithography?

Nanosphere colloidal lithography (NCL) is a versatile and cost-effective technique for patterning surfaces at the nanoscale. It involves the self-assembly of colloidal nanospheres into close-packed monolayers or multilayers, which serve as masks for subsequent deposition, etching, or modification processes. NCL enables the fabrication of ordered nanostructure arrays with controllable size, shape, and spacing, making it a powerful tool for various applications in nanotechnology.

Key Steps in Nanosphere Colloidal Lithography

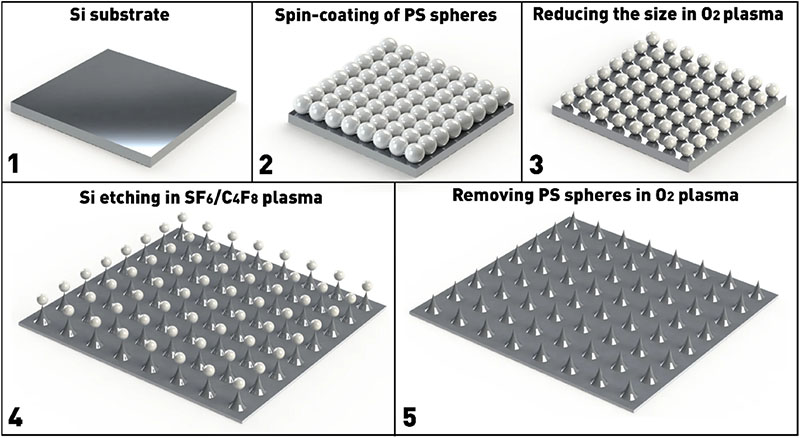

The NCL process typically involves three main steps:

1. Self-Assembly of Colloidal Nanospheres

The first step in NCL is the self-assembly of colloidal nanospheres into a close-packed monolayer or multilayer on a substrate. This is usually achieved by techniques such as spin-coating, dip-coating, or Langmuir-Blodgett deposition. The nanospheres are typically made of materials like polystyrene, silica, or polymethyl methacrylate (PMMA), with diameters ranging from tens to hundreds of nanometers.

2. Deposition or Modification through the Mask

Once the nanosphere mask is formed, the desired material is deposited or the substrate is modified through the interstitial spaces between the nanospheres. This can be done by various methods, such as thermal evaporation, sputtering, chemical vapor deposition, or reactive ion etching. The deposited material forms an array of nanostructures that are complementary to the nanosphere mask.

3. Removal of the Nanosphere Mask

After the deposition or modification step, the nanosphere mask is removed by techniques like sonication or tape stripping. This leaves behind an ordered array of nanostructures on the substrate, with the size, shape, and spacing determined by the original nanosphere mask. The resulting nanostructures can be further processed or functionalized depending on the specific application.

Advantages of Nanosphere Colloidal Lithography

NCL offers several advantages over other nanopatterning techniques:

- Cost-Effectiveness: NCL is a relatively simple and inexpensive technique compared to conventional lithography methods like electron beam lithography or photolithography. It does not require sophisticated equipment or clean room facilities, making it accessible to a wide range of researchers.

- Large-Area Patterning: NCL enables the patterning of large areas (up to several square centimeters) in a single step, which is essential for many practical applications. The self-assembly process of the nanospheres ensures a uniform and ordered pattern over the entire substrate.

- Tunability: The size, shape, and spacing of the nanostructures fabricated by NCL can be easily tuned by controlling the diameter of the nanospheres, the deposition parameters, and the post-processing conditions. This flexibility allows for the fabrication of a wide variety of nanostructures with tailored properties.

Applications of Nanosphere Colloidal Lithography

NCL has found applications in various fields of nanotechnology, including:

Plasmonics and Nanophotonics

NCL is widely used for fabricating plasmonic nanostructures, such as nanodisks, nanoholes, and nanotriangles, which exhibit unique optical properties due to their interaction with light at the nanoscale. These nanostructures have applications in surface-enhanced Raman scattering (SERS), biosensing, and metamaterials.

Solar Energy Harvesting

NCL-fabricated nanostructures can be used to enhance the efficiency of solar cells by increasing light absorption and reducing reflection losses. For example, ordered arrays of metal nanoparticles or nanostructured electrodes can be fabricated by NCL to improve the performance of thin-film solar cells.

Catalysis and Sensing

NCL can be used to create high-surface-area nanostructured catalysts for chemical reactions or sensing applications. The ordered arrays of nanoparticles or nanopores fabricated by NCL provide a large number of active sites for catalytic reactions or analyte binding, leading to enhanced catalytic activity or sensitivity.

Challenges and Future Perspectives

Despite its advantages, NCL also faces some challenges. One of the main limitations is the formation of defects in the nanosphere mask, such as vacancies or dislocations, which can affect the uniformity and reproducibility of the resulting nanostructures. Strategies to improve the quality and long-range order of the nanosphere masks are actively being explored.

Future research in NCL will focus on expanding the range of materials and substrates that can be patterned, as well as developing new self-assembly techniques for creating more complex nanostructures. The combination of NCL with other nanofabrication methods, such as nanoimprint lithography or block copolymer lithography, will enable the fabrication of hierarchical and multi-functional nanostructures for advanced applications.

Further Reading

The Journal of Physical Chemistry B, Nanosphere Lithography: A Versatile Nanofabrication Tool for Studies of Size-Dependent Nanoparticle Optics

Advanced Materials, Nanosphere Lithography: A Versatile Approach to Develop Transparent Conductive Films for Optoelectronic Applications

Journal of Materials Research, Nanosphere lithography fabricated plasmonic materials and their applications