Young's Modulus: Measuring Stiffness at the Nanoscale

What is Young's Modulus?

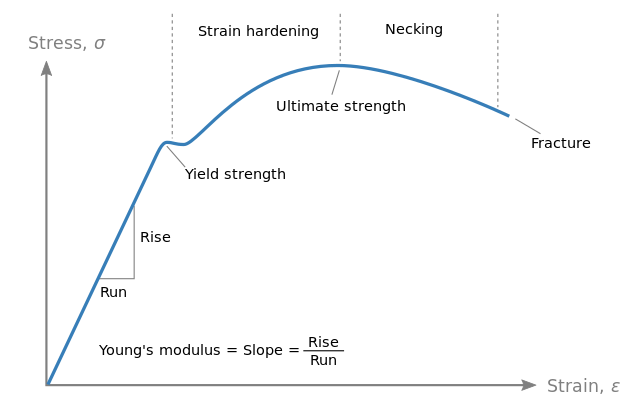

Young's modulus, also known as the elastic modulus, is a mechanical property that measures the stiffness of a solid material. It quantifies the relationship between stress (force per unit area) and strain (proportional deformation) in a material in the linear elastic region of a stress-strain curve. A high Young's modulus indicates a stiff material that resists deformation, while a low modulus characterizes a soft material that is easily deformed.

Calculating Young's Modulus

Young's modulus (E) is calculated as the ratio of stress (σ) to strain (ε) in the linear elastic region of the stress-strain curve:

Where:

- E is Young's modulus (measured in pascals, Pa)

- σ is stress (measured in pascals, Pa)

- ε is strain (dimensionless)

Importance of Young's Modulus in Nanotechnology

Young's modulus plays a crucial role in nanotechnology, as the mechanical properties of materials can significantly differ at the nanoscale compared to their bulk counterparts. Understanding and controlling the stiffness of nanomaterials is essential for various applications, including:

Nanoelectromechanical Systems (NEMS)

NEMS devices, such as nanoscale sensors, actuators, and resonators, rely on the mechanical properties of their constituent materials. The Young's modulus of these materials determines their sensitivity, response time, and overall performance.

Nanocomposites

Nanocomposites are engineered materials that combine a matrix (e.g., polymer) with reinforcing nanomaterials (e.g., carbon nanotubes, graphene). The Young's modulus of the reinforcing nanomaterials significantly influences the mechanical properties of the resulting nanocomposite, allowing for the design of materials with tailored stiffness and strength.

Biomaterials and Tissue Engineering

In the field of biomaterials and tissue engineering, matching the Young's modulus of implants and scaffolds to that of the surrounding biological tissue is crucial for promoting cell adhesion, growth, and differentiation. Nanomaterials with tunable stiffness enable the fabrication of biomimetic substrates that closely resemble the mechanical properties of natural tissues.

Measuring Young's Modulus at the Nanoscale

Measuring Young's modulus at the nanoscale requires specialized techniques that can accurately apply and measure forces and displacements on nanomaterials. Some common methods include:

- Nanoindentation: A technique that uses a sharp tip (indenter) to apply a controlled load to a sample and measures the resulting indentation depth. By analyzing the load-displacement data, the Young's modulus of the material can be calculated.

- Atomic Force Microscopy (AFM): Atomic force microscopy can be used to perform nanoscale mechanical measurements by pressing the AFM tip against the sample and measuring the cantilever deflection. The force-displacement data can be used to calculate the Young's modulus of the material.

- In Situ Electron Microscopy: In situ mechanical testing inside an electron microscope (e.g., TEM, SEM) allows for the direct observation of nanomaterial deformation while simultaneously measuring the applied force and displacement. This technique provides valuable insights into the deformation mechanisms and mechanical properties of nanomaterials.

Further Reading

Nanotechnology Reviews, Mechanical Properties of Nanomaterials: A Review

Physics Education, Measuring Young's modulus with a tensile tester