| May 07, 2019 | |

Coating-boosted interfacial thermal transport for carbon nanotube array nano-thermal interface materials(Nanowerk News) By using Plasma Enhanced Chemical Vapor Deposition approach, Chinese researchers attain DLC (diamond-like carbon)/ TiN (titanium nitride)-coated vertically aligned carbon nanotube (CNT) arrays, which enhances the interfacial thermal transfer (ITT) between array and heat sink. |

|

| Their findings are published in the journal Carbon ("Coating-boosted interfacial thermal transport for carbon nanotube array nano-thermal interface materials"). | |

|

|

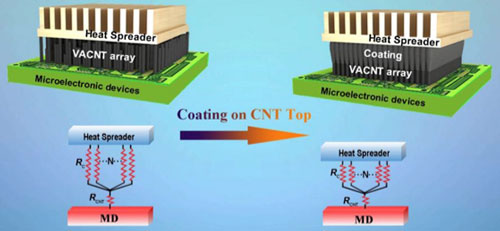

| By applying a DLC/TiN coating to vertically aligned carbon nanotubes, Chinese scientists have reduced the thermal contact resistance between the array and the heat sink by a factor of 50. (Image: University of Science and Technology Beijing) | |

| At present, micro-nano components based on silicon have reached the heat transport limit of the silicon material. On the other hand, due to the ultra-high thermal conductivity and the compatibility with nanometer-sized devices, carbon nanotubes are expected to be the next generation components in micro-nano thermal management. | |

| In fact, CNTs are applied in the form of assembled materials, such as the arrays, while the limited ITT between the heat sink and arrays leads to high interface thermal resistance, which obstruct the application of arrays as micro-nano components. | |

| Although there are some chemical functionalization processes could reduce the high interfacial resistance, the complex process and expensive cost of this method limit its application. Current researchers focus on new methods with inexpensive cost and operability to facilitate ITT between the arrays and the heat sink. | |

| In this study, researchers led by Associate Professor Lin Qiu (Professor Yihui Feng’s research group) from University of Science and Technology Beijing and Professor Beng Kang Tay from Nanyang Technological University have collaborated on the preparation and thermal measurement of multiple DLC / TiN coated array samples. They explored the relationship between contact surface roughness, CNT length, CNT diameter, and contact thermal resistance. | |

| By covering the surface of the array with DLC/TiN, the contact thermal resistance is reduced from 15 mm2 K / W to 0.3 mm2 K / W, which is 50 times lower than the original array. | |

| The researchers open up a new way to improve the interface contact conditions for array-heat sink structures. By controlling the deposition time, the researchers control the roughness and contact area of the array to enhance the effect of the ITT. | |

| The researchers hope that above findings fuel future effort towards realizing industrial application of high-performance array-based nano-thermal interface materials and high-efficiency thermal management in microelectronic and nanoenergy fields. |

| Source: University of Science and Technology Beijing | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |