| Mar 21, 2024 |

New 2D material adhesion and device stability insights

(Nanowerk News) One of the big selling points of two-dimensional (2D) materials is their self-passivated nature, which allows them to be deposited on any substrate and opens up new possibilities for three-dimensional material stacks.

|

|

The downside is their weak adhesion to the substrate, which can be a source of device instability. Quantifying the adhesion of 2D materials to three-dimensional surfaces is therefore an essential step for the reliable integration of devices based on 2D materials. A team of researchers around Max Lemme has now shown that the adhesion between 2D materials and substrates can be efficiently quantified using button-shear testing.

|

|

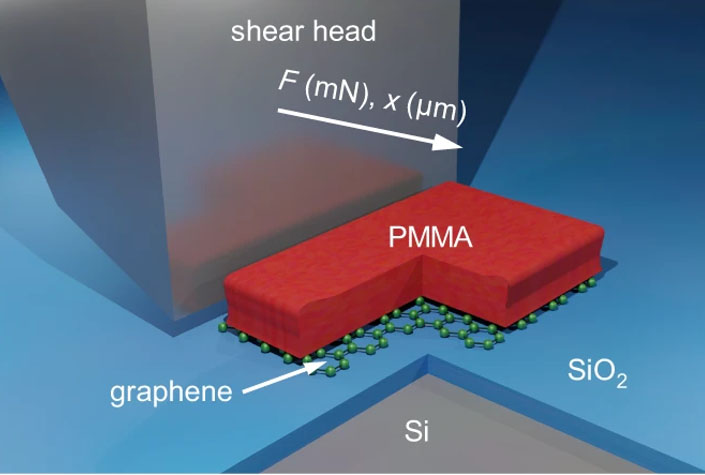

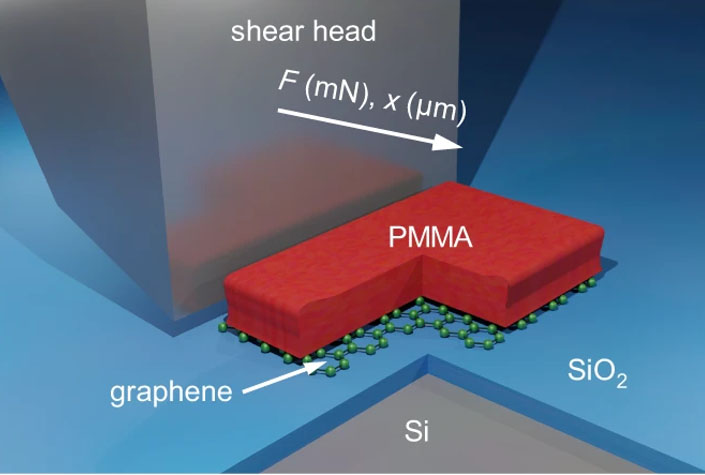

| Schematic representation of the working principle of button shear testing. (Image: AMO)

|

|

Although button shear testing is a well-established method for adhesion measurement in the semiconductor industry, its applicability to quantifying the adhesion of 2D materials remained to be proven. One of the challenges has been, for example, to determine the size of the buttons and the measurement routine required to obtain reliable results.

|

|

The basic principle of button shear testing is quite simple: a polymer button is fabricated on top of the sample and used as a “handle” to move the sample itself by pulling on it with a metallic tip. More precisely, the sample is moved at a constant speed against a fixed shear head, while the position of the stage and the force exerted on the head are simultaneously recorded. The maximum force recorded corresponds to the force required to initiate the shear process and provides information on the adhesion between the sample and the substrate.

|

|

If the principle is simple, the reliability of the method critically depends on the details – in particular on the properties of the buttons and on the speed of the measurements – which need to be carefully tested and optimized for the materials under investigation.

|

|

The results of such a systematic study focused on 2D materials have been now reported in Nature Communications ("Button shear testing for adhesion measurements of 2D materials"). The study is the result of a collaboration between the Chair of Electronic Devices (ELD) at RWTH Aachen University, Infineon Technologies AG and AIXTRON SE. Involved in the study were also AMO GmbH and other academic partners.

|

|

The publication in Nature Communications not only reports the details of the fabrication of the polymer button and the methodology developed per measuring the adhesion of 2D materials – in particular graphene, hexagonal boron nitride, as well as molybdenum disulfide, and tungsten diselenide on silicon dioxide and silicon nitride substrates – but it also shows that the method allows to evaluate the effects of different sample treatments on adhesion, providing important insights for further optimization.

|