| Feb 03, 2012 |

'Bullet-proof' graphene composite tougher than Kevlar

|

|

(Nanowerk News) University of Wollongong (UOW) researchers have used graphene to develop a new composite material which can produce the toughest fibres to date- even tougher than spider silk and Kevlar.

|

|

Graphene, the latest discovery in the nano world of carbon, has proven to be an amazing building block for advanced materials. The new graphene composite can be wet-spun into fibres with potential applications in bullet-proof vests and reinforcements for advanced composite materials.

|

|

As published in Nature Communications ("Synergistic toughening of composite fibres by self-alignment of reduced graphene oxide and carbon nanotubes"; open access), researchers from the UOW-based Centre of Excellence for Electromaterials Science (ACES) have shown that graphene can work just as carbon nanotubes, a more common toughening agent, in polymer composites. It is also a much cheaper material and can be produced easily in large quantities.

|

|

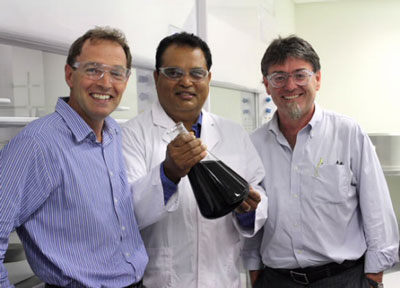

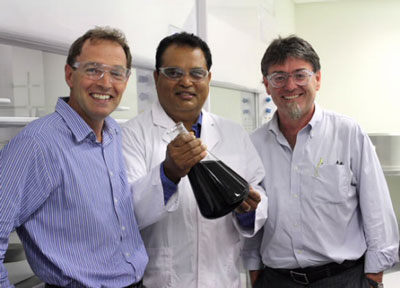

| Professor Geoff Spinks, Dr Sanjeev Gambhir and Professor Gordon Wallace with the new nanocomposite material.

|

|

ACES Senior Researcher and paper co-author Professor Geoff Spinks said the ratio of graphene to carbon nanotubes was a key factor in the development of the composite.

|

|

"Quite surprisingly, we found that a 'magic mixture' of equal parts carbon nanotubes and graphene added to the polymer gave exceptionally high toughness," he said.

|

|

"Fibres made from other combinations of these materials were not especially tough at all."

|

|

Professor Spinks explained that the super tough fibres can be produced easily by a wet-spinning method and can be readily up-scaled. In this case, fibres were spun by collaborators at the Centre for Bio-Artificial Muscle at Hanyang University, Korea.

|

|

ACES Executive Research Director Professor Gordon Wallace said such international collaborations were critical for effective and efficient progress at the cutting edge of science.

|

|

"This particular project benefitted from the supply of the graphene building blocks using a process invented here in Australia and further developed using the skills and facilities available through the Australian National Fabrication Facility- Materials node," he said.

|

|

The team has also supplied graphene materials to other research activities in the USA, Korea and France.

|