| Sep 27, 2012 |

Nanotechnologists create miniscule soccer balls

|

|

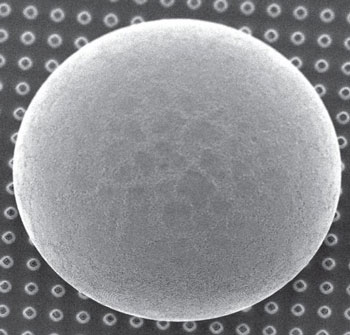

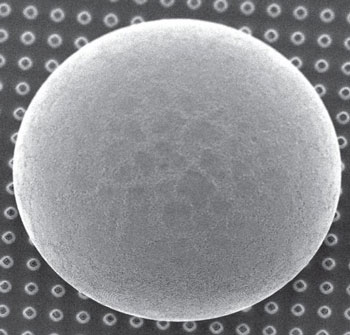

(Nanowerk News) Nanotechnologists at the University of Twente’s MESA+ research institute have developed a method whereby minuscule polystyrene spheres, automatically and under controlled conditions, form an almost perfect ball that looks suspiciously like a football, but about a thousand times smaller. The spheres organize themselves in such a way that they approach the densest arrangement possible, known as ‘closest packing of spheres’. The method provides nanotechnologists with a new way of creating minuscule 3D structures.

|

|

The research was published this week in the leading scientific journal Proceedings of the National Academy of Sciences ("Building microscopic soccer balls with evaporating colloidal fakir drops").

|

|

|

The method developed by the University of Twente scientists involves placing a drop of water containing thousands of polystyrene spheres one micrometre in size (a thousand times smaller than a millimetre) on a superhydrophobic surface. As the drop is allowed to evaporate very slowly under controlled conditions the distances between the spheres become smaller and smaller and surprisingly they form a highly organized 3D structure. The spheres were found to organize themselves of their own accord in such a way that the ball they form approaches the most compact arrangement possible (‘closest packing of spheres’), with 74% of the space filled by the spheres. Like a football, the structures that form are almost perfectly spherical, consisting of a large number of planes. The researchers have therefore dubbed their material ‘microscopic soccer balls’. The minuscule footballs are a hundred to a thousand micrometres in size, containing from ten thousand to as much as a billion of the tiny polystyrene spheres.

|

|

Complex 3D structures

|

|

The research at Twente has produced a new method of creating complex 3D structures of this kind by means of self-assembly. As the scientists are able to precisely control the number of polystyrene spheres and the evaporation rate, they can determine the structure of the end-product with great precision. The method thus provides nanotechnologists with a new way of creating minuscule structures efficiently. They could eventually be used e.g. for medical purposes and in the food industry.

|