| Nov 28, 2023 | |

Revolutionizing nanosurface engineering with novel ultrafast laser technique |

|

| (Nanowerk Spotlight) The ability to controllably structure surfaces at the micro- and nanoscale has remained a profoundly impactful yet challenging goal spanning industrial sectors. Precisely controlling surface topographies at these tiny dimensions unlocks transformative functionalities vital for next-generation technologies. | |

| Structured surface coatings and metamaterials with tailored nanotextures can exhibit extreme water repellency, dynamic optical properties, enhanced tribological performance, and customized adhesion or reactivity. As applications demand ever more advanced materials, the lack of manufacturing methods capable of affordably structuring surfaces with intricate precision from the millimeter scale down to the nanometer<. scale has emerged as a bottleneck slowing progress. | |

| Considerable research has focused on ultrafast laser processing as a versatile nanofabrication platform. Leveraging ultrashort, high-intensity laser pulses enable strikingly controlled ablation and nanomaterial synthesis across diverse material systems. However, despite substantive progress, gaining exhaustive mastery over the resulting heterogeneous surface structures has still proven an enduring challenge limiting adoption. | |

| A new study from Tsinghua University (Frontiers of Optoelectronics, "Localized in‑situ deposition: a new dimension to control in fabricating surface micro/nano structures via ultrafast laser ablation") represents a potential breakthrough in flexible ultrafast laser-based surface nanoengineering. The researchers demonstrate an innovative hybridized fabrication approach combining both laser ablation and in situ nanoparticle deposition within a unified, controllable process. This enables, for the first time, the ability to alternate iteratively between precision material removal and targeted additive nanoparticle assembly during surface structuring. | |

|

|

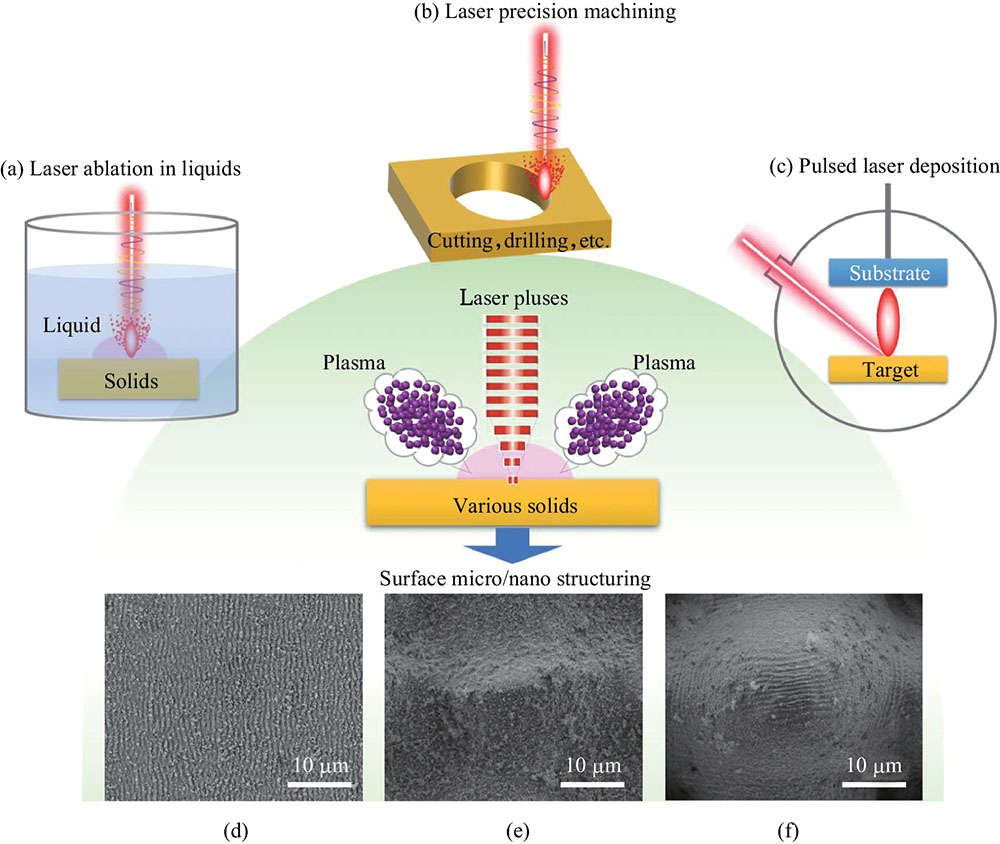

| Overview of the universal plasma-plume formation process during pulsed laser ablation of solids with different laser processing approaches. (a laser ablation in liquids, b laser precision machining, and c pulsed laser deposition) and the varied outcomes after the plasma formation. d–f show the re-deposited particle features randomly distributed on primary surface structures, of different scales, inscribed and induced by ultrafast laser. As can be seen, the re-deposition of energetic species during ultrafast laser surface micro/nano structuring is an in-situ process, distinctive from the approaches in (a − c). (Image: Reprinted from DOI:10.1007/s12200-023-00092-1, CC BY) | |

| As the authors explain, the universal plasma plume dynamics intrinsic to any ultrafast laser ablation process have thus far been overlooked as an exploitable phenomenon for deliberate structuring. Although collateral particle deposition during ablation is known to occur randomly, viewing this as a controllable additive fabrication mechanism had yet to be explored. | |

| By systematically investigating the ablation of tungsten, a remarkably hardy metal, the researchers uncover the parametric dependencies governing both the standard subtractive ablation mechanism and – remarkably – the concurrent additive nanoparticle assembly. Astoundingly, by tuning the laser parameters, these competing mechanisms can be alternated repeatedly in a localized, layered fashion to construct complex hierarchical surface structures. | |

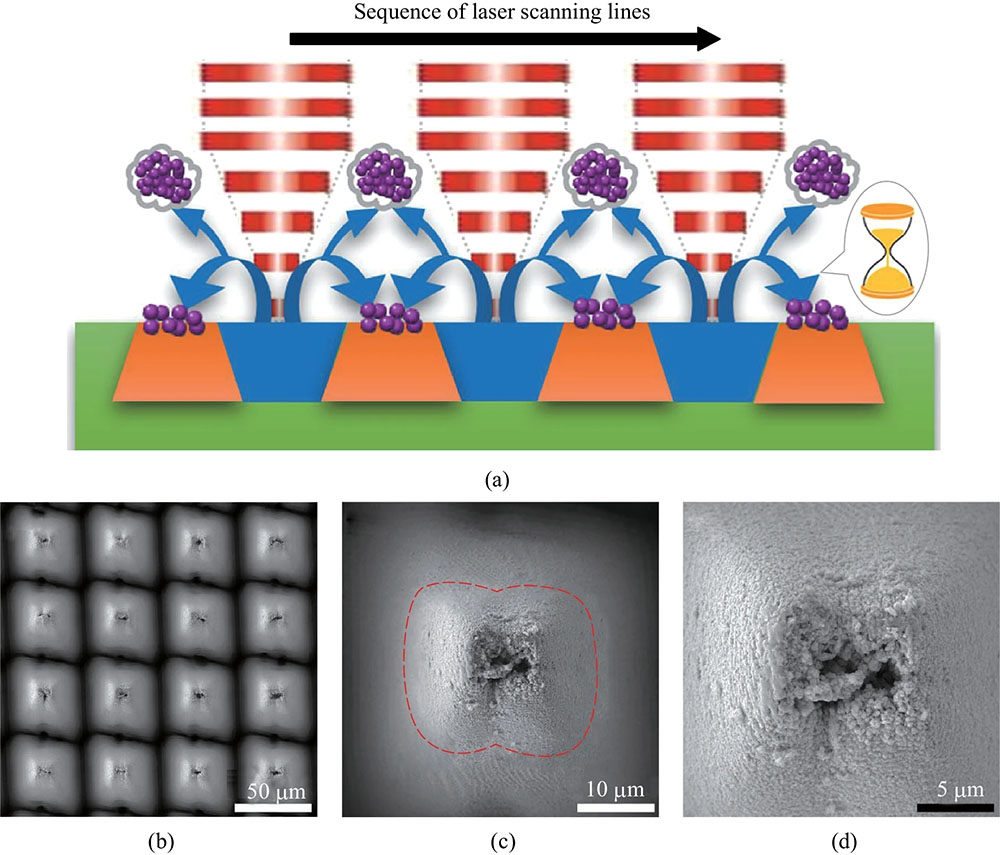

| Specifically, the discovered additive mechanism relies on the in situ self-assembly of laser-generated nanoparticles onto the underlying surface. The researchers demonstrate the structured nanoparticle deposition can be controlled to build upwards in a scanning, layer-by-layer manner akin to powder bed additive manufacturing. This surface-bound additive process is driven by the balance between ablation rate, debris generation, and nanoparticle diffusion/deposition kinetics. | |

| Remarkably, by coordinating these competing effects, complex tiered surface structures become possible. As proof, the authors demonstrate the world’s first hybrid micro cones decorated with intricate fort-like nanostructures. By alternating timed ablation and deposition phases, sturdy micron-sized conic hillocks are constructed layer-by layer. Onto each, intricate castle-like nanostructures are iteratively assembled from nanoparticles. | |

| The research underscores the vast possibilities that likely still exist hidden within ultrafast laser-matter interactions. By expanding the nanoparticles inherent in ablation from mere surface debris into a powerful, controllable building block for additive assembly, entirely new structuring capabilities become accessible. | |

| The demonstrated hybrid subtractive-additive approach points towards next-generation ultrafast laser platforms capable of constructing complex, multi-tiered functional surface topographies. These could enable transformative optical, tribological, wetting, or sensing properties exceeding the possibilities of current approaches. | |

|

|

| a Schematic illustration of the sequential subtractive and additive fabrication processes under femtosecond laser irradiation (Green-Tungsten plate; Blue-Ablated area; Orange-Unablated area. The black arrow shows the sequence of laser scanning lines). b–d SEM images in different magnifications of a particular kind of hierarchical structures prepared via the femtosecond laser ablation and in-situ deposition process. b Micro cone arrays with a periodicity of 50 µm formed by the subtractive ablation process. c Secondary structures (marked within the red dash rectangle) on top of the micro cone arrays formed by the additive in-situ deposition process. d Sub-micro features constituting the secondary structures (© Frontiers of Optoelectronics) | |

| Indeed, as the lead author Dr Peixun Fan explains, their surprising findings reveal “new possibilities in the fabrication of functional surface micro/nano structures using ultrafast lasers”. This pioneering work undoubtedly represents a pivotal moment for the field. | |

| The sophistication possible has likely only scratched the surface. By further elucidating the biphasic ablation-deposition dynamics, ever more intricate and multi-scaled surface architectures should become manufacturable. | |

| In one fell swoop, this ground-breaking study has mastered the particle dynamics that have plagued ultrafast laser surface nanostructuring since its inception, and transformed them into a powerful, liberating additive fabrication tool. | |

| What awaits when both solution-phase nanoparticle assembly and templated crystallization are combined with this hybrid trifecta of laser-sculpting, laser-deposition, and surface-assembly? Exploring these intersecting frontiers may uncover novel hybrid material systems and complex synthetically structured surfaces unmatched by past approaches. | |

| The Tsinghua team’s research opens far more than just new fabrication methods. Their creative inversion of laser-generated nanoparticles from nuisance to nanobuilding-block stands poised to reshape the surface micro- and nano-engineering landscape. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|