Nanotribology: Exploring Friction, Wear, and Lubrication at the Nanoscale

What is Nanotribology?

Nanotribology is the study of friction, wear, and lubrication at the nanoscale. It focuses on understanding and controlling the interactions between surfaces in relative motion when the contact area is on the order of nanometers. Nanotribology plays a crucial role in the development of advanced materials, micro- and nanoelectromechanical systems (MEMS/NEMS), and various applications where surface interactions at the nanoscale are critical.

Key Concepts in Nanotribology

Nanotribology involves several key concepts that distinguish it from conventional tribology:

- Nanoscale Contact Mechanics: Nanotribology deals with the mechanics of contact between surfaces at the nanoscale. The contact area at this scale is typically much smaller than the apparent area, and the surface forces, such as adhesion and capillary forces, become dominant over the bulk properties.

- Single-Asperity Contact: At the nanoscale, the contact between surfaces often occurs through individual surface asperities, known as single-asperity contacts. Understanding the behavior of these single-asperity contacts is crucial for predicting the overall tribological performance of the system.

- Atomic-Scale Friction: Nanotribology investigates friction at the atomic scale, where the sliding motion is influenced by the atomic structure and interactions of the surfaces. Atomic-scale friction can exhibit unique phenomena, such as stick-slip motion and superlubricity, which are not observed at larger scales.

Experimental Techniques in Nanotribology

Nanotribology relies on various experimental techniques to study surface interactions and measure tribological properties at the nanoscale:

Atomic Force Microscopy (AFM)

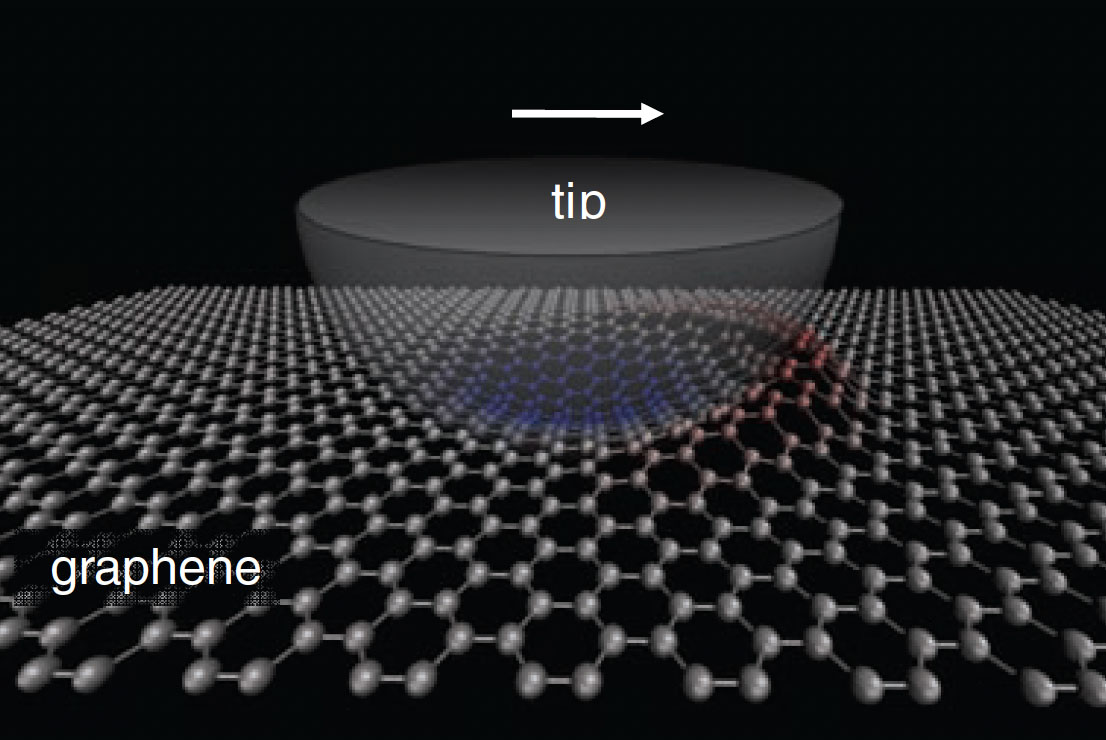

AFM is a powerful tool for nanotribological studies. It uses a sharp tip attached to a cantilever to probe the surface and measure the friction force as the tip slides over the surface. AFM can provide high-resolution images of surface topography and enables the measurement of friction forces with nanoNewton sensitivity.

Friction Force Microscopy (FFM)

FFM is a variant of AFM that focuses specifically on measuring friction forces. In FFM, the lateral deflection of the cantilever is used to quantify the friction force as the tip scans across the surface. FFM allows for the mapping of friction forces with nanoscale spatial resolution.

Surface Force Apparatus (SFA)

SFA is a technique used to measure the forces between two surfaces as a function of their separation distance. It employs two atomically smooth surfaces, typically mica, which are brought into contact and then separated while measuring the interaction forces. SFA provides valuable insights into the adhesion, friction, and lubrication behavior of surfaces at the nanoscale.

Applications of Nanotribology

Nanotribology has numerous applications in various fields:

MEMS/NEMS

Nanotribology is essential for the design and reliability of MEMS and NEMS devices. These devices often have moving parts that come into contact at the nanoscale, and understanding the friction and wear behavior is crucial for ensuring their proper operation and longevity. Nanotribological studies help in selecting suitable materials, surface treatments, and lubrication strategies for MEMS/NEMS applications.

Magnetic Storage Devices

Nanotribology plays a critical role in the development of advanced magnetic storage devices, such as hard disk drives. The read/write head in these devices flies over the magnetic disk surface at a nanoscale separation, and the tribological interactions between the head and the disk surface can significantly impact the device performance and reliability. Nanotribological studies aid in optimizing the head-disk interface for improved data storage density and reduced wear.

Nanomaterials and Nanocomposites

Nanotribology is important for understanding the tribological behavior of nanomaterials and nanocomposites. These materials often exhibit unique friction and wear properties due to their nanoscale structure and high surface-to-volume ratio. Nanotribological studies help in tailoring the surface properties of nanomaterials for specific applications, such as low-friction coatings and wear-resistant nanocomposites.

Challenges and Future Perspectives

Despite the significant progress in nanotribology, several challenges remain. One of the main challenges is bridging the gap between nanoscale tribological studies and macroscale applications. The tribological behavior observed at the nanoscale may not always directly translate to the macroscale, and understanding the scaling effects is crucial for designing effective tribological systems.

Future research in nanotribology will focus on developing advanced experimental techniques and computational models to gain deeper insights into nanoscale friction, wear, and lubrication mechanisms. The integration of nanotribology with other fields, such as materials science, surface chemistry, and bioscience, will lead to the development of novel materials and surfaces with tailored tribological properties. Additionally, the application of nanotribology in emerging areas, such as flexible electronics, biomedical devices, and space exploration, will drive further advancements in this field.

Further Reading

The Journal of Engineering Tribology, Nano-scale wear: A critical review on its measuring methods and parameters affecting nano-tribology

Philosophical Transactions A, Nanotribology, nanomechanics and nanomaterials characterization