Mesoporous Materials: Highly Ordered Nanoporous Structures for Diverse Applications

What are Mesoporous Materials?

Mesoporous materials are a class of nanomaterials characterized by their highly ordered porous structure with pore sizes ranging from 2 to 50 nanometers. These materials possess large surface areas, tunable pore sizes and shapes, and high pore volume, making them attractive for a wide range of applications in catalysis, adsorption, separation, drug delivery, and energy storage.

Synthesis of Mesoporous Materials

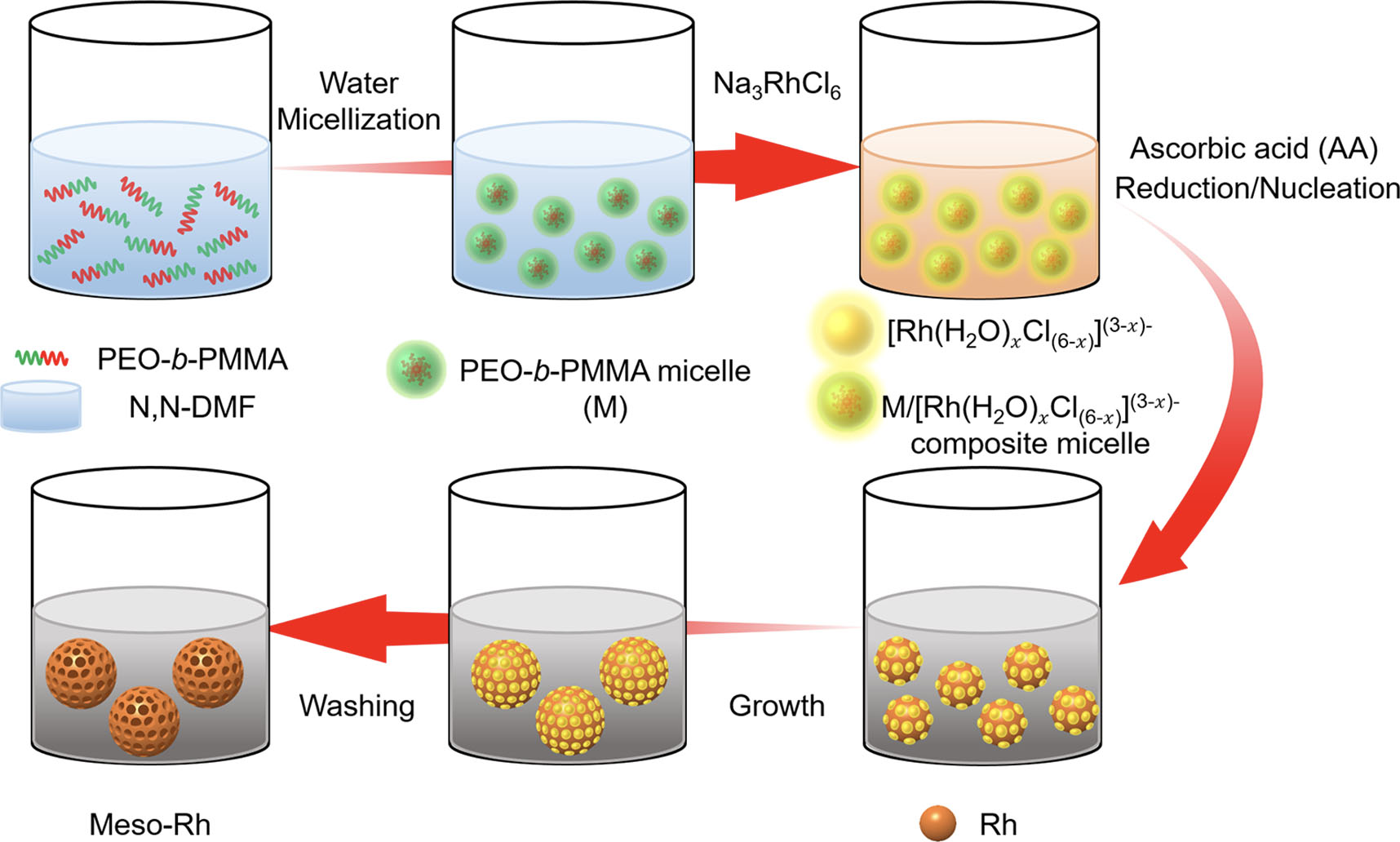

Mesoporous materials are typically synthesized using a templating approach, where a structure-directing agent (template) is used to guide the formation of the porous network. The most common templates are surfactants, such as block copolymers or ionic surfactants, which self-assemble into micellar structures in solution. The inorganic precursor, such as silica or metal oxides, condenses around these micelles, forming a composite material. Upon removal of the template by calcination or extraction, a mesoporous structure with well-defined pores is obtained.

Soft Templating

Soft templating involves the use of supramolecular assemblies of surfactants or block copolymers as structure-directing agents. These templates are flexible and can adapt to various pore geometries. Examples of soft-templated mesoporous materials include MCM-41 (Mobile Composition of Matter No. 41) and SBA-15 (Santa Barbara Amorphous-15), which are based on silica and have hexagonal and cubic pore structures, respectively.

Hard Templating

Hard templating, also known as nanocasting, utilizes rigid, preformed templates such as mesoporous silica or carbon. The desired material is infiltrated into the pores of the template, followed by the removal of the template to obtain a replica of the original porous structure. This approach allows for the synthesis of mesoporous materials with various compositions, including metals, metal oxides, and polymers.

Properties and Characterization

Mesoporous materials exhibit several unique properties that make them attractive for various applications:

- High Surface Area: Mesoporous materials have large specific surface areas, typically ranging from 500 to 1500 m2/g, due to their nanoscale pores and high pore volume. This high surface area provides abundant active sites for catalysis, adsorption, and other surface-dependent processes.

- Tunable Pore Size and Shape: The pore size and shape of mesoporous materials can be precisely controlled by adjusting the synthesis conditions and the choice of template. This tunability allows for the optimization of pore structure for specific applications, such as size-selective catalysis or controlled drug release.

- Diverse Composition: Mesoporous materials can be synthesized from a wide range of inorganic and organic precursors, enabling the development of materials with various chemical compositions and functionalities. Examples include mesoporous silica, alumina, titania, carbon, and metal-organic frameworks (MOFs).

The characterization of mesoporous materials involves several techniques to probe their porous structure, surface properties, and chemical composition. Some commonly used characterization methods include:

- Nitrogen Adsorption-Desorption Isotherms: This technique provides information on the specific surface area, pore size distribution, and pore volume of mesoporous materials using the Brunauer-Emmett-Teller (BET) and Barrett-Joyner-Halenda (BJH) methods.

- Small-Angle X-ray Scattering (SAXS): SAXS is used to determine the long-range ordering and periodicity of the porous structure, providing insights into the pore geometry and arrangement.

- Transmission Electron Microscopy (TEM): Transmission Electron Microscopy allows for the direct visualization of the porous structure and the determination of pore size and shape at the nanoscale.

- Solid-State Nuclear Magnetic Resonance (NMR) Spectroscopy: NMR techniques, such as 29Si and 13C NMR, provide information on the local chemical environment and the bonding of the framework atoms in mesoporous materials.

Applications of Mesoporous Materials

The unique properties of mesoporous materials have led to their application in various fields:

Catalysis

Mesoporous materials are widely used as catalysts and catalyst supports due to their high surface area, tunable pore size, and ability to host active metal nanoparticles. They can enhance the activity, selectivity, and stability of catalytic processes by providing easy access to reactants and controlling the diffusion of products. Examples include mesoporous silica-supported metal catalysts for hydrogenation, oxidation, and coupling reactions.

Adsorption and Separation

The large surface area and tunable pore size of mesoporous materials make them excellent adsorbents for the removal of pollutants, such as heavy metals, dyes, and volatile organic compounds, from water and air. They can also be used for the separation of gases and liquids based on size exclusion or specific interactions with the pore surface.

Drug Delivery

Mesoporous materials, particularly mesoporous silica nanoparticles (MSNs), have shown great potential as drug delivery vehicles. The porous structure allows for the loading of drug molecules, while the surface can be functionalized with targeting ligands or stimuli-responsive groups for controlled release. MSNs can improve the bioavailability, stability, and targeting efficiency of therapeutic agents.

Energy Storage and Conversion

Mesoporous materials are used in various energy-related applications, such as lithium-ion batteries, supercapacitors, and fuel cells. They can serve as electrode materials or electrolyte additives, enhancing the charge transport, ionic conductivity, and electrochemical stability of the devices. Mesoporous carbons, in particular, have shown promise as high-performance electrode materials for supercapacitors.

Challenges and Future Perspectives

Despite the significant progress in the synthesis and application of mesoporous materials, several challenges remain. One of the main challenges is the scalability and cost-effectiveness of the synthesis methods, particularly for large-scale industrial applications. The development of sustainable and environmentally friendly templating strategies is also an important consideration.

Future research in mesoporous materials will focus on the design of novel porous architectures with hierarchical and multi-level pore structures, combining micro-, meso-, and macroporosity. The integration of mesoporous materials with other functional nanomaterials, such as nanoparticles, nanowires, and graphene, will create new opportunities for advanced applications in sensing, optoelectronics, and biomedicine. Additionally, the exploration of mesoporous materials derived from renewable resources and bioinspired synthesis approaches will contribute to the development of sustainable and eco-friendly materials.

Further Reading

Journal of Sol-Gel Science and Technology, An extensive review on mesoporous silica from inexpensive resources: properties, synthesis, and application toward modern technologies

The Chemical Record, A Review of Recent Developments of Mesoporous Materials

Materials Research Express, Advances of typical mesoporous materials and the application in drug delivery