Nanoprinting: Fabricating Nanoscale Structures with Precision

What is Nanoprinting?

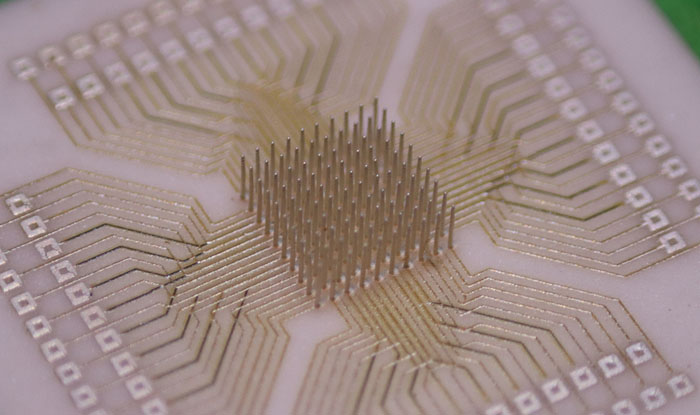

Nanoprinting is a family of techniques used to fabricate nanoscale structures, patterns, and devices with high precision and resolution. It involves the controlled deposition or removal of materials at the nanometer scale, enabling the creation of intricate features and functionalities for various applications, such as electronics, photonics, and biomedicine.

Key Techniques in Nanoprinting

Several nanoprinting techniques have been developed to achieve high-resolution patterning and fabrication at the nanoscale:

Nanoimprint Lithography (NIL)

Nanoimprint lithography is a high-throughput nanoprinting technique that uses a patterned mold or stamp to transfer nanoscale features onto a substrate. The mold, typically made of a hard material like silicon or quartz, is pressed into a polymer resist material, which deforms and replicates the mold's pattern. After curing and mold removal, the patterned resist can be used as a mask for subsequent etching or deposition processes.

Dip-Pen Nanolithography (DPN)

Dip-pen nanolithography is a scanning probe-based nanoprinting technique that uses an atomic force microscope (AFM) tip to directly write or deposit molecules onto a substrate with nanoscale precision. The AFM tip, coated with the desired molecules, acts as a "pen" that transfers the "ink" to the substrate through capillary transport. DPN enables the patterning of a wide range of materials, including proteins, DNA, and polymers.

Inkjet Printing

Inkjet printing, although originally developed for macroscale printing, has been adapted for nanoprinting applications. In this technique, tiny droplets of nanoink containing functional materials like nanoparticles or conductive polymers are precisely deposited onto a substrate using a print head. By controlling the droplet size and placement, nanoscale patterns and structures can be created with high resolution.

Advantages of Nanoprinting

Nanoprinting offers several advantages over conventional nanofabrication methods:

- High Resolution: Nanoprinting techniques can achieve feature sizes down to a few nanometers, enabling the fabrication of ultra-small structures and devices.

- Low Cost: Compared to traditional lithography methods like electron beam lithography, nanoprinting techniques are generally more cost-effective, as they can be performed using relatively simple equipment and materials.

- High Throughput: Some nanoprinting techniques, such as nanoimprint lithography, are capable of high-throughput fabrication, allowing for the rapid production of large-area nanostructures.

- Versatility: Nanoprinting can be applied to a wide range of materials, including polymers, metals, and biomolecules, making it suitable for diverse applications.

Applications of Nanoprinting

Nanoprinting has found applications in various fields, leveraging its ability to create nanoscale structures and patterns with unique properties and functionalities:

Nanoelectronics

Nanoprinting is used to fabricate nanoelectronic components, such as transistors, memory devices, and sensors. By patterning conductive materials and creating high-resolution features, nanoprinting enables the development of miniaturized and high-performance electronic devices.

Nanophotonics

In the field of nanophotonics, nanoprinting techniques are employed to create nanoscale optical structures, such as photonic crystals, plasmonics devices, and metamaterials. These nanostructures can manipulate light at the nanoscale, enabling applications in optical computing, sensing, and imaging.

Biomedical Applications

Nanoprinting is used to fabricate nanostructured biomaterials, biosensors, and drug delivery systems. By patterning biomolecules and creating nanostructured surfaces, nanoprinting can enhance the performance and functionality of biomedical devices and facilitate the study of cellular interactions and responses.

Challenges and Future Perspectives

Despite the significant progress in nanoprinting technologies, several challenges remain to be addressed. One of the main challenges is the scalability of nanoprinting processes, particularly for large-area and high-volume production. The development of high-throughput and roll-to-roll nanoprinting methods is crucial for industrial-scale applications.

Another challenge is the limited availability of suitable materials for nanoprinting, especially for applications that require specific optical, electrical, or mechanical properties. The development of novel functional materials and inks compatible with nanoprinting processes is an active area of research.

Future research in nanoprinting will focus on improving the resolution, throughput, and reliability of nanoprinting techniques. The integration of nanoprinting with other nanofabrication methods, such as self-assembly and directed assembly, will enable the creation of complex and hierarchical nanostructures. Additionally, the exploration of new applications, such as in flexible electronics, wearable devices, and personalized medicine, will drive the further development of nanoprinting technologies.

Further Reading

Nature Nanotechnology, An all-in-one nanoprinting approach for the synthesis of a nanofilm library for unclonable anti-counterfeiting applications

Nature Communications, 3D nanoprinting via spatially controlled assembly and polymerization

Journal of Micromechanics and Microengineering, A review of non-contact micro- and nano-printing technologies