| Aug 13, 2019 | |

Directly observing the way ceramic materials fracture on the atomic scale(Nanowerk News) For the first time, researchers have been able to observe the way ceramic materials fracture on the atomic scale. They confirm that the arrangement of molecules between grains within a body of ceramic material strongly affects the way a fracture propagates through it (Nature Communications, "Direct observation of atomic-scale fracture path within ceramic grain boundary core"). |

|

| This research could help materials scientists to develop tougher useful materials from new or existing constituent substances. | |

|

|

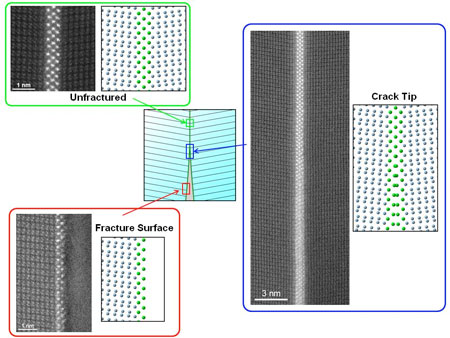

| Schematic diagrams next to scanning transmission electron microscope images of a ceramic fracture. (Image: Yuichi Ikuhara) (click on image to enlarge) | |

| Ceramic materials are extremely useful. You can find them in things such as small devices like smartphones to large engineered structures like buildings. However they are used, engineers generally prefer them to be tough and robust, so their applications are as reliable as can be. Although ceramics are quite resistant in some ways, for example to heat, they can also be quite brittle and can fracture easily. This can limit their usefulness. | |

| “Ceramic materials comprise different shaped grains of inorganic metals and nonmetals. Fractures generally propagate along boundaries between grains as these regions are structurally weak,” said Professor Yuichi Ikuhara from the Institute of Engineering Innovation. “These kinds of cracks are called grain boundary fractures. If we understood them better it’s likely we could create more resilient ceramics, so we explore the fracture process on the atomic scale.” | |

| Ikuhara and team investigated grain boundary fractures in ceramics of aluminium oxide (Al2O3). They successfully managed for the first time to characterize the fracture process at the atomic level. Their finding describes the way bonds between atoms along a grain boundary are broken and how this in turn affects the successive propagation of the fracture. | |

|

|

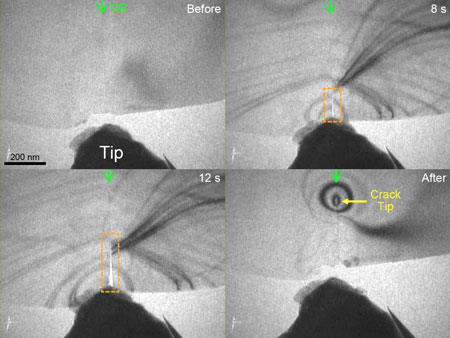

| Scanning transmission electron microscope image of the fracture as it happened. (Image: Yuichi Ikuhara) (click on image to enlarge) | |

| “To see this happening, we had to view our ceramic samples with a scanning transmission electron microscope (STEM), which can image samples down to the atomic level,” continued Ikuhara. “This was itself quite difficult as we had to come up with a way to intentionally fracture the sample inside the machine. But we successfully observed the dynamic grain boundary fracture behavior with STEM by precisely controlling the geometry of the sample and the tool to fracture it.” |

| Source: University of Tokyo | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |