| Posted: May 20, 2014 | |

Nanotechnology in food quality control: Preventing food from biting back (page 1 of 4) |

|

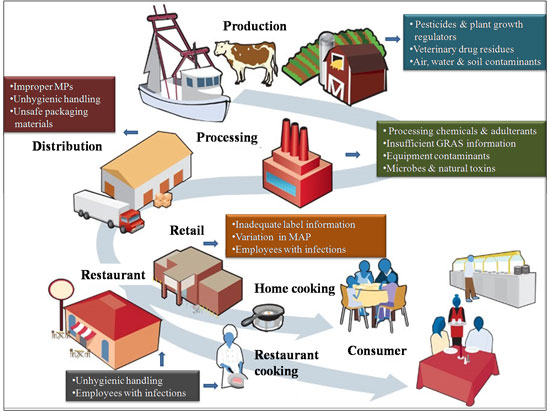

| (Nanowerk Spotlight) To keep the market sustainability and leadership in the food industry, it is essential to present flavourful, fresh, authentic and safe food products to consumers with prolonged shelf life. In addition, government authorities pose stringent regulatory standards throughout the food logistics to ensure food safety until consumption. However, on their journey from manufacturer to consumer that includes processing, handling and distribution, the quality of food is impaired by various agrochemicals, veterinary drug residues, adulterants, microbial contaminants, and environmental factors (Fig. 1). | |

|

|

| Fig. 1: Potential sources of contamination in the consumable food. MPs: Manufacturing practices, GRAS: Generally recognized as safe, MAP: Modified atmosphere packaging. (Image: CKMNT; adapted from Centres for Disease Control and Prevention (CDC), USA) (click image to enlarge) | |

| Though packaging materials protect foodstuffs from extensive sensory exposure, their marked sell-by-date is based on manufacturer’s idealized storage and transportation assumptions, which may not be strictly followed by distributers. Due to the colour change and other sensory characterstics, the spoiled and unpalatable food products can be easily discerned by consumers and if not, might be a reason for foodborne illness. Thus, to minimise the risk of infection to the population through the contaminated food supply chain, rapid detection of pathogens and chemical residues while ensuring the food freshness is necessary prior to their consumption. | |

| “Any sufficiently advanced technology is indistinguishable from magic" (Arthur C. Clarke). | |

| The statement of this famous futurist is particularly true in the case of nanotechnology-based molecular sensing, where the detection limits are ‘magically’ becoming smaller, reaching even the zepto-molar concentrations with ultra-sensitive multiplexed detection capabilities1. | |

| Analytical chemistry plays a prominent role in food quality control and has already started taking advantages from the versatility and novel merits of nanoscience. The unique electro-optical and chemical properties of nanomaterials enable them to be used in array biosensors/lab-on-chips, electronic noses & tongues, test-strips, cantilevers, radio-frequency identification (RFID) tags, surface-enhanced Raman scattering (SERS) nanoprobes, immuno-nanodipsticks, etc. to detect the presence of various contaminants in complex food matrices and to revolutionize the testing speed and accuracy of food regulatory agencies. | |

| Nanomaterials such as metal, metal oxide & magnetic nanoparticles (NPs), carbon nanotubes (CNTs), graphene, ZnO/Au/Ag nanorods, quantum dots (QDs), metal oxide/polymeric/silicon nanowires, cellulose nitrate/optical/photonic nanofibers, etc. are playing a prominent role in designing sensing platforms having lower detection limits to improve the performance of conventional methods for food analysis applications. | |

| In food quality testing methods/devices, nanomaterials have various advantages over conventional materials such as ultra-sensitivity, selectivity, multiple targeting, portability, reproducible data processing, implantable conformability, on-board intelligence, non-invasive testing of packaged items, etc. | |

| Some of the recent and significant developments in the area of nanotechnology applications for food quality control are discussed in the following subsections. | |

| Detection of Gaseous Content, Moisture and Spoilage | |

| Excessive moisture and oxygen are among the prominent reasons of food spoilage however, most of the available analytical assays or sensors to examine gas or vapour content in the packaged food demand opening of the package2. | |

| Of late, various nanotechnology-based non-invasive gas sensing methods have been devised, facilitating the examination of residual oxygen content of vacuum packed food and modified atmosphere packaging (MAP) during the period of transportation and storage. | |

| Researchers from Amity Institute of Advanced Research and Studies, India have developed a nano TiO2-based implantable sensor for detecting air leakage in packed food items. This sensor gives colorimetric indication of air leakage as well as shows measurable change in electrical behaviour on air exposure and can be reused many times without any loss in the photosensivity3. Also, an ultra low-cost porous optical humidity sensor based on carbon-coated CuNPs has been developed by scientists at Swiss Federal Institute of Technology, Zurich for detecting the moisture content in food items in humid environments4. | |

| The majority of currently available implantable food quality sensors are rigid, non-disposable, and flat wafers, which lack conformability for curved interfaces especially those of fruits. | |

| A research team from Tufts University, USA in collaboration with other university colleagues has developed an edible, biodegradable, eco-friendly, and low-cost sensor consists of a nanopatterned AuNPs plasmonic array on silk that conforms to the shape of a variety of fruits such as curved surfaces of apple and banana or even can be immersed in liquids such as milk. The sensor is similar to an antenna-based passive device like RFID tag that does not need power to operate. It detects changes in the dielectric properties during the fruit ripening or bacterial contamination in milk/cheese while emitting an electromagnetic signal5. | |

| Continue to next page (2 of 4) | |

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|