Showing Spotlights 25 - 32 of 33 in category All (newest first):

The future of your clothes will be electronic. Not only will electronic devices be embedded on textile substrates, but an electronics device or system could become the fabric itself. These electronic textiles will have the revolutionary ability to sense, compute, store, emit, and move - think biomedical monitoring functions or new man-machine interfaces, not to mention game controllers - while leveraging an existing low-cost textile manufacturing infrastructure. In new work, a group of scientists from Korea have now reported novel method for the fabrication of conductive, flexible, and durable graphene textiles wrapped with reduced graphene oxide.

The future of your clothes will be electronic. Not only will electronic devices be embedded on textile substrates, but an electronics device or system could become the fabric itself. These electronic textiles will have the revolutionary ability to sense, compute, store, emit, and move - think biomedical monitoring functions or new man-machine interfaces, not to mention game controllers - while leveraging an existing low-cost textile manufacturing infrastructure. In new work, a group of scientists from Korea have now reported novel method for the fabrication of conductive, flexible, and durable graphene textiles wrapped with reduced graphene oxide.

Oct 29th, 2013

In new work, researchers have demonstrated that flexible cotton threads can be used as a platform to fabricate a cable-type supercapacitor. Wearable electronics will go far beyond just very small electronic devices or wearable, flexible computers. Not only will these devices be embedded in textile substrates but an electronics device or system could ultimately become the fabric itself. Supercapacitors with a cable-type architecture could lead to flexible energy storage devices that can remove traditional restriction and achieve a subversive technology that could open up a path for design innovation.

In new work, researchers have demonstrated that flexible cotton threads can be used as a platform to fabricate a cable-type supercapacitor. Wearable electronics will go far beyond just very small electronic devices or wearable, flexible computers. Not only will these devices be embedded in textile substrates but an electronics device or system could ultimately become the fabric itself. Supercapacitors with a cable-type architecture could lead to flexible energy storage devices that can remove traditional restriction and achieve a subversive technology that could open up a path for design innovation.

Aug 29th, 2013

The future of electronics will be flexible. Not only will you be able to roll up your iPads and smart phones like a piece of paper, electronic devices will be invisibly embedded in the textiles you wear from baby diapers to doctors' surgical gloves. To realize such devices, equally flexible power sources need to be integrated with the electronic devices. Textile yarns are an obvious choice. Researchers are already pushing ahead with electronic textiles (e-textiles), for instance by coating regular cotton yarns with single-walled and multi-walled carbon nanotubes and polyelectrolytes, thus making cotton fibers conductive. Addressing the power source issue, researchers have now found a simple way to provide cotton with a new function - storing energy.

The future of electronics will be flexible. Not only will you be able to roll up your iPads and smart phones like a piece of paper, electronic devices will be invisibly embedded in the textiles you wear from baby diapers to doctors' surgical gloves. To realize such devices, equally flexible power sources need to be integrated with the electronic devices. Textile yarns are an obvious choice. Researchers are already pushing ahead with electronic textiles (e-textiles), for instance by coating regular cotton yarns with single-walled and multi-walled carbon nanotubes and polyelectrolytes, thus making cotton fibers conductive. Addressing the power source issue, researchers have now found a simple way to provide cotton with a new function - storing energy.

Jun 25th, 2012

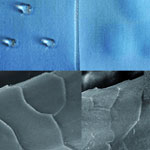

'Nano Textiles' can be produced by a variety of methods. The key difference among them is whether synthetic nanoparticles are integrated into the fibres or the textile, or are applied as a coating on the surface, and/or whether nanoparticles are added to the nanoscale fibres or coating. This article clarifies nano-textile manufacturing processes and application areas, and gives an overview about the potential effects on the environment and health. Many questions remain unanswered, however, there is a need for considerably more research not only for product development but also into the usefulness and risks which nano-textiles give rise to. The open questions have prompted the Swiss Textile Federation to undertake a joint project with the Swiss Federal Laboratories for Materials Science and Technology (EMPA) entitled 'Nanosafe Textiles' and to initiate discussions on the topic.

'Nano Textiles' can be produced by a variety of methods. The key difference among them is whether synthetic nanoparticles are integrated into the fibres or the textile, or are applied as a coating on the surface, and/or whether nanoparticles are added to the nanoscale fibres or coating. This article clarifies nano-textile manufacturing processes and application areas, and gives an overview about the potential effects on the environment and health. Many questions remain unanswered, however, there is a need for considerably more research not only for product development but also into the usefulness and risks which nano-textiles give rise to. The open questions have prompted the Swiss Textile Federation to undertake a joint project with the Swiss Federal Laboratories for Materials Science and Technology (EMPA) entitled 'Nanosafe Textiles' and to initiate discussions on the topic.

Dec 16th, 2010

Nanotechnology shows great potential for revolutionizing the textile industry across its entire range of applications with its ability to impart new functionality to textiles while at the same time maintaining their look and feel. The wool textile industry, for example, is researching the development of textiles with fast-absorbing and quick-drying properties. This has great importance for improving clothing thermophysiological comfort and wearing performance by adjusting the transport of heat and moisture through a fabric which was usually achieved using synthetic fibers. One stubborn hurdle that prevents nanotechnology-enabled 'smart' textiles from becoming more of a commercial reality is the insufficient durability of nanocoatings on textile fibers or the stability of various properties endowed by nanoparticles. Quite simply put, the 'smart' comes off during washing. Developing an effective approach to enhance the coalesce force between nanoparticles and wool fibers has great significance both in scientific and real applications of nanotechnology functionalized textiles.

Nanotechnology shows great potential for revolutionizing the textile industry across its entire range of applications with its ability to impart new functionality to textiles while at the same time maintaining their look and feel. The wool textile industry, for example, is researching the development of textiles with fast-absorbing and quick-drying properties. This has great importance for improving clothing thermophysiological comfort and wearing performance by adjusting the transport of heat and moisture through a fabric which was usually achieved using synthetic fibers. One stubborn hurdle that prevents nanotechnology-enabled 'smart' textiles from becoming more of a commercial reality is the insufficient durability of nanocoatings on textile fibers or the stability of various properties endowed by nanoparticles. Quite simply put, the 'smart' comes off during washing. Developing an effective approach to enhance the coalesce force between nanoparticles and wool fibers has great significance both in scientific and real applications of nanotechnology functionalized textiles.

Oct 12th, 2010

If current research is an indicator, wearable electronics will go far beyond just very small electronic devices or wearable, flexible computers. Not only will these devices be embedded in textile substrates but an electronics device or system could ultimately become the fabric itself. Electronic textiles (e-textiles) will allow the design and production of a new generation of garments with distributed sensors and electronic functions. Such e-textiles will have the revolutionary ability to sense, act, store, emit, and move - think biomedical monitoring functions or new man-machine interfaces - while ideally leveraging an existing low-cost textile manufacturing infrastructure. A recent research report proposes to make conductive, carbon nanotube-modified cotton yarn. This would offer a uniquely simple yet remarkably functional solution for smart textiles - close in feel and handling to normal fabric - yet with many parameters exceeding existing solutions.

If current research is an indicator, wearable electronics will go far beyond just very small electronic devices or wearable, flexible computers. Not only will these devices be embedded in textile substrates but an electronics device or system could ultimately become the fabric itself. Electronic textiles (e-textiles) will allow the design and production of a new generation of garments with distributed sensors and electronic functions. Such e-textiles will have the revolutionary ability to sense, act, store, emit, and move - think biomedical monitoring functions or new man-machine interfaces - while ideally leveraging an existing low-cost textile manufacturing infrastructure. A recent research report proposes to make conductive, carbon nanotube-modified cotton yarn. This would offer a uniquely simple yet remarkably functional solution for smart textiles - close in feel and handling to normal fabric - yet with many parameters exceeding existing solutions.

Nov 14th, 2008

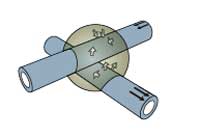

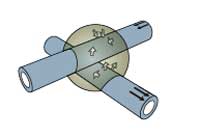

In the future, wearable electronics will go far beyond just very small electronic devices. Not only will such devices be embedded on textile substrates, but an electronics device or system could become the fabric itself. Electronics textiles will allow the design and production of a new generation of garments with distributed sensors and electronic functions. Such e-textiles will have the revolutionary ability to sense, act, store, emit, and move (think biomedical monitoring functions or new man-machine interfaces) while leveraging an existing low-cost textile manufacturing infrastructure. Reporting a novel approach through the construction of all-organic wire electrochemical transistor devices (WECT) , researchers in Sweden show that textile monofilaments can be coated with continuous thin films of a conducting polymer and used to create microscale WECTs on single fibers. They also demonstrate inverters and multiplexers for digital logic. This opens an avenue for three-dimensional polymer micro-electronics, where large-scale circuits can be designed and integrated directly into the three-dimensional structure of woven fibers.

In the future, wearable electronics will go far beyond just very small electronic devices. Not only will such devices be embedded on textile substrates, but an electronics device or system could become the fabric itself. Electronics textiles will allow the design and production of a new generation of garments with distributed sensors and electronic functions. Such e-textiles will have the revolutionary ability to sense, act, store, emit, and move (think biomedical monitoring functions or new man-machine interfaces) while leveraging an existing low-cost textile manufacturing infrastructure. Reporting a novel approach through the construction of all-organic wire electrochemical transistor devices (WECT) , researchers in Sweden show that textile monofilaments can be coated with continuous thin films of a conducting polymer and used to create microscale WECTs on single fibers. They also demonstrate inverters and multiplexers for digital logic. This opens an avenue for three-dimensional polymer micro-electronics, where large-scale circuits can be designed and integrated directly into the three-dimensional structure of woven fibers.

Apr 4th, 2007

If current research is an indicator, wearable electronics will go far beyond just very small electronic devices. Not only will such devices be embedded on textile substrates, but an electronics device or system could become the fabric itself. Electronics textiles will allow the design and production of a new generation of garments with distributed sensors and electronic functions. Such e-textiles will have the revolutionary ability to sense, act, store, emit, and move (think biomedical monitoring functions or new man-machine interfaces) while leveraging an existing low-cost textile manufacturing infrastructure. Today, only a few steps towards new architectural possibilities of realizing circuit topologies that can be implemented with textile technique have been made: one an example of nonplanar devices and one of textile based devices. Researchers in Italy have now developed an organic field effect transistor (OFET) fully compatible with textile processing techniques.

If current research is an indicator, wearable electronics will go far beyond just very small electronic devices. Not only will such devices be embedded on textile substrates, but an electronics device or system could become the fabric itself. Electronics textiles will allow the design and production of a new generation of garments with distributed sensors and electronic functions. Such e-textiles will have the revolutionary ability to sense, act, store, emit, and move (think biomedical monitoring functions or new man-machine interfaces) while leveraging an existing low-cost textile manufacturing infrastructure. Today, only a few steps towards new architectural possibilities of realizing circuit topologies that can be implemented with textile technique have been made: one an example of nonplanar devices and one of textile based devices. Researchers in Italy have now developed an organic field effect transistor (OFET) fully compatible with textile processing techniques.

Nov 21st, 2006

The future of your clothes will be electronic. Not only will electronic devices be embedded on textile substrates, but an electronics device or system could become the fabric itself. These electronic textiles will have the revolutionary ability to sense, compute, store, emit, and move - think biomedical monitoring functions or new man-machine interfaces, not to mention game controllers - while leveraging an existing low-cost textile manufacturing infrastructure. In new work, a group of scientists from Korea have now reported novel method for the fabrication of conductive, flexible, and durable graphene textiles wrapped with reduced graphene oxide.

The future of your clothes will be electronic. Not only will electronic devices be embedded on textile substrates, but an electronics device or system could become the fabric itself. These electronic textiles will have the revolutionary ability to sense, compute, store, emit, and move - think biomedical monitoring functions or new man-machine interfaces, not to mention game controllers - while leveraging an existing low-cost textile manufacturing infrastructure. In new work, a group of scientists from Korea have now reported novel method for the fabrication of conductive, flexible, and durable graphene textiles wrapped with reduced graphene oxide.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed