| Jul 25, 2022 |

Fundamentals underpinning future atomic and close-to-atomic scale manufacturing

(Nanowerk News) Atomic and close-to-atomic scale manufacturing (ACSM) represents the processing techniques for high-end products, which requires not only the atomic-level manufacturing precision and functional feature size, but also the material removal, migration, or addition at the atomic or close-to-atomic scale.

|

|

Benefiting from the special quantum, electromagnetic, and thermal effects at atomic or close-to-atomic scale, ACSM shows great potentials for the manufacturing of future-generation chips, single-electron transistors, quantum bits, spin-based logic devices, atomically binary gates, and single-atom memory.

|

|

Despite the substantial rewards that ACSM can offer, the challenges it presents are enormous, especially when using traditional manufacturing tools. This is because the challenges of implementing ACSM lie not only in the extreme small scale at which it can be machined, but also in the fundamental understanding of atomic interactions, which are based on the quantum theory rather than classical theory.

|

|

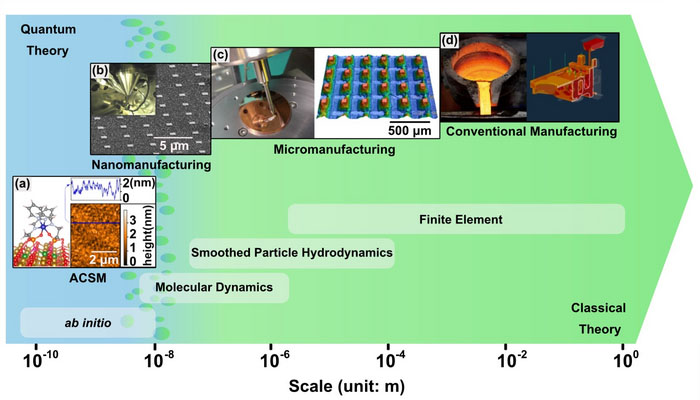

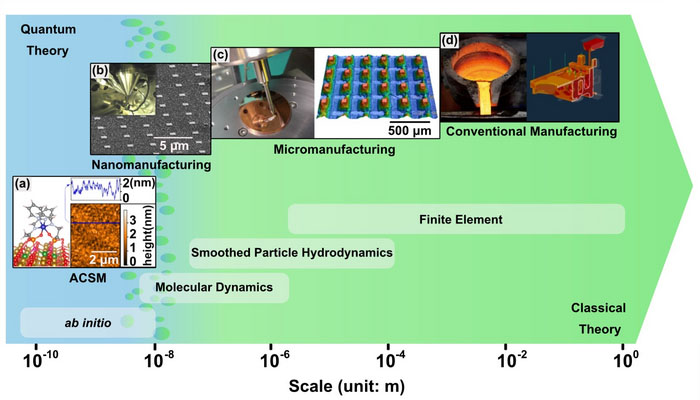

| A length scale map of manufacturing systems, modelling methods, and dominant theories. It summarizes the manufacturing systems, modelling methods, and dominant theories across the length scales, and it shows that ACSM is governed by quantum theory, while micromanufacturing and conventional manufacturing are governed by classical theory. In nanomanufacturing, when the length scale is below 10 nm, quantum effects start to become more apparent. When the de Broglie wavelength is larger than the system scale or inter-particle distances, quantum theory becomes dominant. Such a nanomanufacturing system is then governed by quantum theory. (Image: Jian Gao, Xichun Luo, Fengzhou Fang, Jining Sun)

|

|

Prof. Xichun Luo and his PhD student Jian Gao from Centre for Precision Manufacturing in University of Strathclyde, Prof. Fengzhou Fang from Tianjin University and University College Dublin, and Prof. Jining Sun from Dalian University of Technology, wrote a review paper in the International Journal of Extreme Manufacturing ("Fundamentals of atomic and close-to-atomic scale manufacturing: A review") that discussed and summarized the fundamentals of ACSM processes, aiming to identify the intrinsic problems preventing its realization.

|

|

The authors begin with a discussion on the quantum mechanics in manufacturing and then builds on this to explain the nature of atom-atom and energy beam-matter interactions. The mechanisms of several ACSM processes were subsequently summarized and their modelling techniques were reviewed to introduce the development in the simulation research. After a discussion on the current studies, future fundamental research of ACSM is proposed in terms of process modelling, material selection or preparation, and control of manufacturing tools and environments.

|

|

Despite the success made in experimental and theoretical research, ACSM is still in its infancy and challenges still exist in several aspects, including achieving deterministic manufacturing and product stability.

|

|

First, atomic-scale resolution requires manufacturing tools to achieve effective control over atoms or atom clusters. The interactions that dominate this process are quantum mechanics. The phenomena of the interactions are uncertain in nature; as a result, ACSM can be difficult to perform and is subject to uncertainty.

|

|

Second, even when atomic-scale structures are successfully fabricated, maintaining their stability is an enormous challenge. Atoms that construct atomic-scale patterns are usually accompanied by a very low atom diffusion barrier. The self-diffusion processes can easily damage structural integrity and compromise functions. In the manufacturing of single-atom transistors, atomic-scale patterns on semiconductors could decompose and migrate on the surface, like water droplets on a hot plate.

|

|

Manufacturing determinism can be improved by increasing the patterning resolution as this enables control of a small number of atoms without disturbing other surrounding atoms. Manufacturing tools and processed substrate materials can interact in different ways, but the attainable resolution at a manufacturing zone depends on the feature size of the interaction region, where physical or chemical reaction that dominates the manufacturing occurs. Therefore, minimizing the interaction region is the key to enhance the resolution and determinism of ACSM processes.

|

|

When atomic or close-to-atomic scale patterns are manufactured, some measures are required to sustain their stability so that the manufactured structures will maintain their functionality. The stability of the structures could be related to the material???s physical properties, the surface lattice structure, the processing history, and environmental effects.

|

|

However, fundamentally, the two important determinants of stability are surface chemical reactivity and the structural properties related to lattice structure and atomic interactions. To provide long-term cyclic stability, atomic or close-to-atomic scale structures must be specially designed or modified and a rational selection of substrate material is required.

|

|

Professor Xichun Luo, Mr. Jian Gao, Professor Fengzhou Fang and Professor Jining Sun have identified a few challenges in the fundamental study of ACSM processes: ???Apparently, quantum mechanics governs the interactions in ACSM. How to use this theory to efficiently model the manufacturing process????

|

|

???First-principles calculation is the most direct and accurate method to calculate the quantum mechanical effect, but the calculation requires high computational power. In order to provide an effective and reliable simulation for larger scale systems, several advanced simulation approaches could be used, including Reaxff molecular dynamics simulation, machine learning-based multiscale simulation, hybrid classical and quantum-mechanical simulation and molecular dynamics simulation using potentials from first-principles calculations.???

|

|

???In order to achieve ACSM, is it necessary to use tools with atomic or close-to-atomic scale size? For example, utilizing atomic-sharp tips, atomic-size ion or electron beams????

|

|

???Atomic tool and beam size will certainly improve the manufacturing determinism as they will interact with fewer atoms. In general, the manufacturing resolution is more directly related to the size of the interaction region, where physical or chemical reaction that dominate the manufacturing occurs. In some manufacturing process, the size of the interaction region will be smaller than the tool size, allowing the process to obtain a much smaller structure than the manufacturing tool.???

|

|

???Material selection seems to be a key issue in ACSM. From a fundamental point of view, what are the requirements for materials????

|

|

???Choosing or preparing suitable work materials will determine the interatomic ???force??? and thus improve the probability of forming expected patterns and stabilise atomic-scale patterns. To create atomic-scale patterns, materials need to meet two conditions: i) materials should respond to the interaction with good sensitivity because ACSM normally delivers small force or energy; ii) materials should be accompanied with relatively stable structures to maintain the atomic-scale patterns, normally with high defect diffusion barriers.???

|