| Jan 05, 2012 |

It's stressful being gold

|

|

(Nanowerk News) When putting together a medical sensor for blood protein levels, researchers at the London Centre for Nanotechnology combined gold moving parts with chemical sensing molecules, and were able for the first time to study this interaction. In order to visualise the sensors they made, an extensive collaboration between researchers from many disciplines was formed, using facilities from London cleanrooms to a Photon Source in Chicago.

|

|

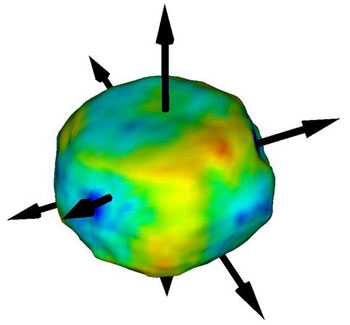

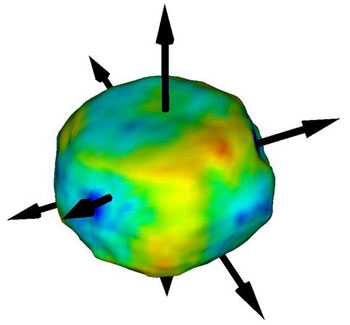

LCN researchers have discovered the way that chemical changes on the surface of gold are transmitted to its interior. This is of particular significance in biosensors, which are often based on small gold structures. The smaller these devices are made, the more sensitive they become, therefore it is important to examine on the smallest scale. It was found that an individual nanometre-sized grain of gold becomes distorted when a single layer of molecules are attached, such as those that would be used in sensing. Coherent X-ray Diffraction, a technique pioneered in the LCN, has been used to study these tiny structures. This allows the LCN researchers to visualise the strains that connect the chemical changes in the sensor with a physical movement.

|

|

| Colour-coded images of surface strains in a gold nanocrystal. Strain is concentrated in the crystal's corners, away from the facets (indicated by outward-pointing arrows).

|

|

While the motivation of the work is medical, the development of in vivo sensors of blood protein levels and other chemicals, the readout mechanism is physical, namely measuring the deflection of a micro cantilever cut out of silicon. The sensing mechanism is chemical, using 'thiol' linker molecules which bind simultaneously to the inorganic gold coating on one side of the cantilevers and the organic medium in which the sensed molecules live.

|

|

The LCN team, which recently published their results in Nature Materials ("Differential stress induced by thiol adsorption on facetted nanocrystals"), represents the kind of broad collaboration that arose from the diverse academic interests of the authors, who are based at the UCL and Imperial College sites of the LCN. Dr Rachel McKendry led the team measuring the effectiveness of cantilever arrays as sensors. Prof Ian Robinson led the X-ray diffraction expedition, as he put it "all the way to Chicago to use the 'Advanced Photon Source', one of the brightest sources of X-rays in the world. The experiments could be completed only by close collaboration between all these parties."

|

|

Prof Robinson said of this work "While this experiment demonstrates on the nanometre scale the effects of surface tension, a simple chemical principle which has been known since the time of Lord Rayleigh, considerable skill was needed from a team of co-workers. Moyu Watari, who actually performed the experiment, did not sleep for days to stabilise the equipment and watch out for the tiny changes. She had to make the samples and transfer them immediately into to the experimental station under a non-reactive nitrogen atmosphere. Ross Harder built and maintained the instrumentation, which had to remain stable on the nanometre scale for many hours. A robot actually dispensed the active chemical to avoid disturbing the setup. Hundreds of workers are responsible for the stable day-to-day running of the X-ray synchrotron machine, a factory-scale production of X-rays that are shared by as many as 50 groups of researchers at one time. The success of this experiment is a credit to the teamwork and central planning needed to provide such facilities. In the modern scientific world with live communication, there is no longer need for cutthroat competition. All scientists can get together and build a single excellent facility, such as the Advanced Photon Source, and share it efficiently in pursuit of their individual scientific interests."

|