| Posted: May 06, 2008 | |

Nanotechnology? What are you talking about? |

|

| (Nanowerk Spotlight) Ask 10 people what nanotechnology is and you will get 10 different answers. | |

| Trying to define nanotechnology is like the famous tale of the blind men and the elephant: Six blind men were asked to determine what an elephant looked like by feeling different parts of the elephant's body. The blind man who feels a leg says the elephant is like a pillar; the one who feels the tail says the elephant is like a rope; the one who feels the trunk says the elephant is like a tree branch; the one who feels the ear says the elephant is like a hand fan; the one who feels the belly says the elephant is like a wall; and the one who feels the tusk says the elephant is like a solid pipe. It's the same with nanotechnology – it is different things to different people. | |

| And then there are all these terms floating around: 'bottom-up' and 'top-down' fabrication, 'atomically precise manufacturing', 'molecular assembly', 'self-assembly', 'nanorobots', 'nanofactories' and so forth. Try describing nanotechnology as a top-down fabrication process and the folks over at Foresight and CRN will tell you what a short-sighted wuss you are. Try describing nanotechnology the Drexlerian way as a bottom-up molecular assembly technology and some scientists will tell you that you are smoking too much of the good stuff. | |

| And then of course you hear about all these 'nanotechnology' products already hitting the market – but they seem decidedly low-tech, such as golf balls, 'no-smell' socks, toothpaste, scratch-resistant car paint, and so on – that's what we have been investing billions and billions of dollars for? | |

| Pretty confusing, huh? Let's start to disentangle... | |

Definition of nanotechnology |

|

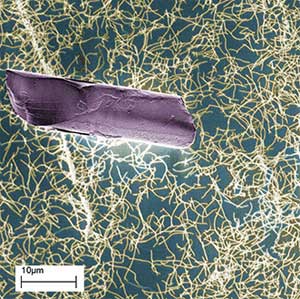

| One of the problems facing nanotechnology is the confusion about its definition. Most definitions revolve around the study and control of phenomena and materials at length scales below 100 nanometers (nm) and the most overused comparison you read about all the time is that with a human hair, which is about 80,000 nm wide. | |

|

|

| Human hair fragment and a network of single-walled carbon nanotubes (Image: Jirka Cech) | |

| Some definitions include a reference to molecular systems and devices and nanotechnology 'purists' argue that any definition of nanotechnology needs to include a reference to "functional systems". The inaugural issue of Nature Nanotechnology in 2006 asked 13 researchers from different areas what nanotechnology means to them and the responses, from enthusiastic to skeptical, reflect a variety of perspectives. | |

| Another important criteria for the definition is the requirement that the nano-structure is man-made. Otherwise you would have to include every naturally formed biomolecule and material particle, in effect redefining much of chemistry and molecular biology as 'nanotechnology.' | |

| The most important requirement for the nanotechnology definition is that the nano-structure has special properties that are exclusively due to its nanoscale proportions. | |

| We found a good definition that is practical and unconstrained by any arbitrary size limitations (source): | |

| The design, characterization, production, and application of structures, devices, and systems by controlled manipulation of size and shape at the nanometer scale (atomic, molecular, and macromolecular scale) that produces structures, devices, and systems with at least one novel/superior characteristic or property. | |

The relevance of the nanoscale |

|

| The bulk properties of materials often change dramatically when reduced to nanoscale dimensions. This has to do with two main reasons: | |

| Firstly, nanomaterials have a relatively larger surface area when compared to the same mass of material in bulk form. This can make materials more chemically reactive (in some cases materials that are inert in their larger form are reactive when produced in their nanoscale form), and affect their strength or electrical properties. | |

| To understand the effect of particle size on surface area, consider a U.S. silver dollar. The silver dollar contains 26.96 grams of coin silver, has a diameter of about 4 centimeters, and has a total surface area of approximately 27.70 square centimeters. If the same amount of coin silver were divided into tiny particles – say 1 nanometer in diameter – the total surface area of those particles would be 11,400 square meters. In other words: when the amount of coin silver contained in a silver dollar is rendered into 1 nm particles, the surface area of those particles is over 4 million times greater than the surface area of the silver dollar! (Source) | |

| Secondly, quantum effects can begin to dominate the behavior of matter at the nanoscale – particularly at the lower end – affecting the optical, electrical and magnetic behavior of materials. Materials can be produced that are nanoscale in one dimension (for example, very thin surface coatings), in two dimensions (for example, nanowires and nanotubes) or in all three dimensions (for example, nanoparticles and quantum dots). | |

| Composites made from particles of nano-size ceramics or metals smaller than 100 nanometers can suddenly become much stronger than predicted by existing materials-science models. For example, metals with a so-called grain size of around 10 nanometers are as much as seven times harder and tougher than their ordinary counterparts with grain sizes in the hundreds of nanometers. | |

| The causes of these drastic changes stem from the weird world of quantum physics. The bulk properties of any material are merely the average of all the quantum forces affecting all the atoms. As you make things smaller and smaller, you eventually reach a point where the averaging no longer works and you have to deal with the specific behavior of individual atoms or molecules – behavior that can be very different to when these atoms are aggregated into a bulk material. | |

Nanotechnology will develop in generations |

|

| As we reported previously (Nanotechnology manufacturing key to industrialized countries' future competitiveness), systematic control and manufacture at the nanoscale are envisioned to evolve in four overlapping generations of new nanotechnology product types that start with nanoscale building blocks and evolve over time into complex heterogeneous systems. Each anticipated generation of products will provide a nanotechnology base for further innovation, leading to succeeding generations of products of increasing complexity and functionality: | |

| First Generation (beginning ∼2000): passive nanostructures, illustrated by nanostructured coatings, nanoparticles, dispersion of nanoparticles, nanocomposites, and bulk nanostructured materials ? nanostructures made of metals, polymers, ceramics; bio-building blocks. The nanotech sunscreens and golf balls that you read about are only incremental improvements of previous products where thanks to the use of such passive nanostructures – in the case of sunscreen zinc oxide or titanium dioxide; and carbon nanotubes in the case of golf balls – better performance characteristics could be achieved. | |

| Second Generation (beginning ∼2005): active nanostructures, illustrated by transistors, amplifiers, targeted drugs and chemicals, biological and non-biological sensors, actuators, and adaptive structures. | |

| Third Generation (beginning ∼2010): three-dimensional nanosystems and systems of nanosystems using various synthesis and assembly techniques such as bio-assembly, networking at the nanoscale, and multiscale architectures. | |

| Fourth Generation (beginning ∼2015): materials by design and heterogeneous molecular nanosystems, where each molecule in the nanosystem has a specific structure and plays a different role. Molecules will be used as devices, and from their engineered structures and architectures will emerge fundamentally new functions. | |

A platform technology |

|

| Nanotechnology is not an industry; nor is it a single technology or a single field of research. What we call nanotechnology consists of sets of enabling technologies applicable to many traditional industries (that?s why it would be more correct to speak of nanotechnologies in the plural). | |

| You often hear nanotechnology described as a "platform technology" – these are technologies that are so pervasive that they serve as springboards for other technologies and as foundations for many diverse applications; they are also regarded as essential for progress in multiple fields. Computer operating systems are a good example for a platform technology. Rather than having to deal with computer hardware directly, programmers work with an abstraction of the underlying hardware (the operating systems) to build diverse applications from games to control software for nuclear power plants. | |

| In a similar fashion, nanotechnologies will allow the precise control of individual atoms and molecules, leading to an unprecedented ability in many diverse areas to develop new materials, devices or medical treatments. | |

| There are different ways of manipulating matter at the nanoscale. The two notions you hear most are 'top-down' and 'bottom-up' methods. | |

Top-down and bottom-up |

|

| Michelangelo was a ?top-down? artist. He took one big, raw block of Carrara marble and after years of chiseling away produced David. In the process he reduced the original block of marble to half its original volume and left the other half as waste. This is the nanotechnology equivalent of lithography and other top-down methods where you start by taking a block of material and remove the bits and pieces you don?t want until you get the shape and size you do want. In the process you spend (relatively much) energy, use (sometimes very toxic) chemicals, produce (often quite a bit of) waste, need a lot of patience (these processes are relatively slow) and often the results are quite unique and not easily replicable. | |

|

|

| Marble - before and after Michelangelo's top-down approach | |

| Bottom-up methods are much more elegant and efficient. Take lego blocks. Just pick the shape and sizes you need and – one by one – build more or less anything you want with them. Replace your hands with a (tiny) machine, or some other assembly process, and the legos with atoms or molecules and you have molecular assembly. Unfortunately, this analogy is too simplistic. | |

| To make things a bit more complicated, there are two fundamentally different ways of fabricating things from the bottom up. And this is where a lot of the confusion about the different nanotechnology terminology comes from. | |

| One bottom-up method is nature?s way: self-assembly. Self-organizing processes are common throughout nature and involve components from the molecular (e.g. protein folding) to the planetary scale (e.g. weather systems) and even beyond (e.g. galaxies). The key to using self-assembly as a controlled and directed fabrication process lies in designing the components that are required to self-assemble into desired patterns and functions. Self-assembly reflects information coded – as shape, surface properties, charge, polarizability, magnetic dipole, mass, etc. – in individual components; these characteristics determine the interactions among them. | |

| On a very small scale you wouldn't even use 'self-assembly' but rather 'chemical synthesis' – the processes chemists have refined over many years. However, the stability of covalent bonds enables the synthesis of almost arbitrary configurations of only up to 1000 atoms. Larger molecules, molecular aggregates, and forms of organized matter more extensive than molecules cannot be synthesized bond-by-bond. Self-assembly is one strategy for organizing matter on these larger scales (Source). | |

| This technique can be summarized as follows: We have no clue why certain atoms and molecules self-assemble the way they do, but once we can initiate and control the process we can use it to build structures from the bottom-up – atom by atom. | |

| Self-assembly has become an especially important concept in nanotechnology. As miniaturization reaches the nanoscale, conventional manufacturing technologies fail because it has not been possible yet to build machinery that assembles nanoscale components into functional devices (for more on this, read Mind the gap - nanotechnology robotics vision versus lab reality). Until robotic assemblers capable of nanofabrication can be built, self-assembly - together with chemical synthesis - will be the necessary technology to develop for bottom-up fabrication. | |

| Exploiting nature?s self-assembly tricks is real science and it's happening in labs already. As a matter of fact, it's actually about to lead to real world products. A recent example is IBM?s announcement of self-assembling structures in their airgap processors. | |

| Self-assembly is also the reason why nanotechnologies have such a profound impact on the chemical industry. One example is the huge area of polymers used for industrial products (think plastics). Chemists are using molecules' tendency to self-align to design molecular structures with specific properties. Once you know how certain nanoparticles behave and what properties they possess you can use this knowledge to deliberately create structures with desired properties. This is a much more efficient way than the cement mixer chemistry of old where you mix compounds in a more or less arbitrary way based on best guesses and see what materials you get and then try figure out what you could do with them. | |

| The other way of doing bottom-up nanotechnology is man's way: molecular assembly. It sounds like self-assembly but it is a very different concept. If you take a look at the nanofactory animation 'Molecular desktop manufacturing Productive Nanosystems: From Molecules to Superproducts' you?ll get the idea: | |

| This is the vision that proponents or revolutionary nanotechnology put forward: molecular assembly as a factory concept, assembly lines and all, just scaled down to the nano level. The notion of 'self-assembly' becomes relevant in this context with regard to 'self-replicating' nanomachines, i.e. machines that self-assemble themselves; but this is very different from the type of self-assembly found in nature. | |

| There is one – very big – catch though: Today, universal molecular assembly is a vision; in a scientific sense it is not even a theoretical concept yet. | |

| With our technical capabilities today, the most advanced bottom-up nanotechnologies are a combination of chemical synthesis and self-assembly. But they already allow us to perform atomically precise manufacturing on a modest scale and this will lead to vastly improved materials, much more efficient manufacturing processes and entirely new medical procedures. And we haven't seen the end yet of where nanotechnology "doing it nature's way" will lead. Maybe we will never have, and never need, molecular assembly modeled after today's factories. | |

| Here is some food for thought: if nature can grow and operate incredibly complex systems such as humans, maybe our technological future is 'wet' – where factories seem like archaic, crude flintstone-like tools, 'machines' are really more like organisms, and we 'grow' everything we need. That would be 'green' and environmentally compatible technology in the truest sense. And nobody will talk about 'nanotechnology' anymore. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|