| Posted: Jun 02, 2017 | |

3D-printed, fully integrated wireless sensor devices |

|

| (Nanowerk Spotlight) Self-sustaining sensor platforms to continuously monitor the surrounding environment are core components for Internet-of-Things (IoT) and smart-grid systems. These sensor networks will lead to new applications in security, health and environmental monitoring. To make this practicable, the sensors need to be highly integrated, low-cost and small size. | |

| Researchers at King Abdullah University of Science and Technology (KAUST) have now demonstrated a fully integrated and packaged wireless sensor for environmental monitoring applications. The disposable sensor was developed using low-cost additive manufacturing technologies; namely, inkjet printing and 3D printing. | |

| Already, passive components such as inductors, capacitors and antennas have been fabricated via additive manufacturing processes such as 3D printing and inkjet printing. Researchers have also demonstrated 3D-printed sensors. | |

| However, there has been no demonstration of 3D-printed fully-integrated System-on-Package (SoP) employing inkjet-printed sensors which has been shown in this work, just published in Advanced Materials Technologies ("3D-Printed Disposable Wireless Sensors with Integrated Microelectronics for Large Area Environmental Monitoring"). | |

| "The significance of our work is the demonstration of a highly integrated, 3D-printed functional package which not only encloses the traditional electronics but also has sensors and antennas inkjet-printed on its walls," Atif Shamim, and Associate Professor of Electrical Engineering at KAUST, tells Nanowerk. "Such a System-on-Package has not been shown before using additive manufacturing technology. Our work could pave the way for low-cost disposable fully integrated wireless sensor nodes." | |

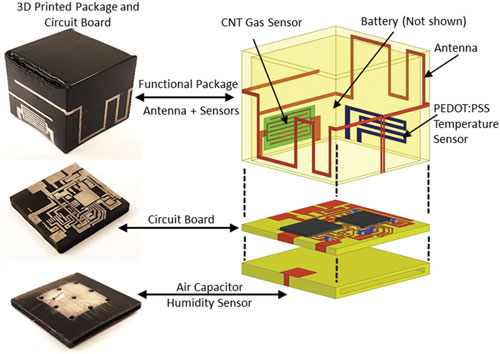

| The team developed a wireless sensor node that incorporates multiple fully inkjet-printed sensors to monitor humidity, temperature, and H2S gas levels. The sensors have been inkjet-printed on the walls of the 3D-printed sensor package which has resulted in a reduction in size of the wireless sensor node. | |

| The cube-shaped functional package also contains the 3D antenna which ensures equal radiation in all directions, thus enabling orientation insensitive communication. The microelectronics has also been realized on a 3D-printed circuit board that is enclosed in the package. | |

|

|

| Device assembly. The sensor node is comprised of an assembly of a 3D-printed functional package, circuit board, and the air capacitor. (Reprinted with permission from Wiley-VCH Verlag. (click on image to enlarge) | |

| Currently, these sensor devices rely on a high-capacity battery to be powered; which limits their lifetime or requires battery change. Something that is completely impractical for many remote and large-scale environmental monitoring applications. And, from an environmental point of view, it really doesn't make these sensors "disposable". | |

| "Of course, ambient energy harvesting capabilities, such as solar cells (inkjet-printed complete solar cells already have been demonstrated), RF harvesting can also be incorporated in the sensor package to make the system truly self-sustained," says Khaled N. Salama, an Associate Professor of Electrical Engineering at KAUST. | |

| According to the researchers, these steps can potentially bring the cost of the sensor down to less than a dollar. | |

| The team is already working on protoypes that will include 3D-printed, fully integrated, self-sustainable, trackable wireless sensor nodes. | |

| "One of the challenges is to reduce printing duration which can solved by the availability of multimaterial 3D printers which can deposit metal, dielectric and other functional inks at the same time," says Shamin. "Such printers are currently not available." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|