Showing Spotlights 137 - 144 of 152 in category All (newest first):

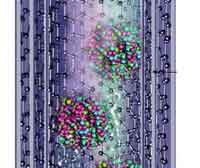

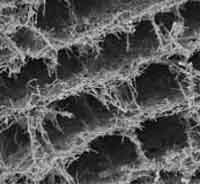

A revolutionary new environmental biotechnology - the Microbial Fuel Cell - turns the treatment of organic wastes into a source of electricity. Fuel cell technology, despite its recent popularity as a possible solution for a fossil-fuel free future, is actually quite old. The principle of the fuel cell was discovered by German scientist Christian Friedrich Schoenbein in 1838 and published in 1839. Based on this work, the first fuel cell was developed by Welsh scientist Sir William Robert Grove in 1843. The operating principle of a fuel cell is fairly straightforward. It is an electrochemical energy conversion device that converts the chemical energy from fuel (on the anode side) and oxidant (on the cathode side) directly into electricity. Today, there are many competing types of fuel cells, depending on what kind of fuel and oxidant they use. Many combinations of fuel and oxidant are possible. For instance, hydrogen cell uses hydrogen as fuel and oxygen as oxidant. Other fuels include hydrocarbons and alcohols. An interesting - but not commercially viable yet - variant of the fuel cell is the microbial fuel cell (MFC) where bacteria oxidize compounds such as glucose, acetate or wastewater. Researchers in Spain have fabricated multi-walled carbon nanotube (MWCNT) scaffolds with a micro-channel structure in which bacteria can grow. This scaffold structure could be used as electrodes in microbial fuel cells.

A revolutionary new environmental biotechnology - the Microbial Fuel Cell - turns the treatment of organic wastes into a source of electricity. Fuel cell technology, despite its recent popularity as a possible solution for a fossil-fuel free future, is actually quite old. The principle of the fuel cell was discovered by German scientist Christian Friedrich Schoenbein in 1838 and published in 1839. Based on this work, the first fuel cell was developed by Welsh scientist Sir William Robert Grove in 1843. The operating principle of a fuel cell is fairly straightforward. It is an electrochemical energy conversion device that converts the chemical energy from fuel (on the anode side) and oxidant (on the cathode side) directly into electricity. Today, there are many competing types of fuel cells, depending on what kind of fuel and oxidant they use. Many combinations of fuel and oxidant are possible. For instance, hydrogen cell uses hydrogen as fuel and oxygen as oxidant. Other fuels include hydrocarbons and alcohols. An interesting - but not commercially viable yet - variant of the fuel cell is the microbial fuel cell (MFC) where bacteria oxidize compounds such as glucose, acetate or wastewater. Researchers in Spain have fabricated multi-walled carbon nanotube (MWCNT) scaffolds with a micro-channel structure in which bacteria can grow. This scaffold structure could be used as electrodes in microbial fuel cells.

Aug 9th, 2007

Finding out how much power all the computers in the U.S., not to mention the world, are using seems to be an impossible task. We tried. The latest data from the Department of Energy (DoE) for household computer use is from 2001, for office use, from 1999. This is strange because when you do some back of the envelope calculations you arrive at some pretty staggering numbers. An estimated 1 billion computers in 2008 will use some 200 billion kWh of electricity (that's roughly what all households in New York City combined use over five years), generating about 127 million tonnes of CO2 in the process. And that's just for desktop and laptop computers, not including peripherals or the billions of chips used in other electronic devices. Researchers are now proposing to build a fully mechanical computer based on nanoelectromechanical (NEMS) components that would use considerably less energy. Inspired by a classical mechanical computer design from 200 years ago, the main motivation behind constructing such a computer is threefold: (1) mechanical elements are more robust to electromagnetic shocks than current dynamic random access memory (DRAM) based purely on complimentary metal oxide semiconductor (CMOS) technology, (2) the power dissipated can be orders of magnitude below CMOS and (3) the operating temperature of such an NMC can be an order of magnitude above that of conventional CMOS. Today, such a mechanical computer is only a hypothetical device. However, any effort to reduce the power consumption of computers, and not increase them as happens with every new chip generation, seems like a worthwhile effort.

Finding out how much power all the computers in the U.S., not to mention the world, are using seems to be an impossible task. We tried. The latest data from the Department of Energy (DoE) for household computer use is from 2001, for office use, from 1999. This is strange because when you do some back of the envelope calculations you arrive at some pretty staggering numbers. An estimated 1 billion computers in 2008 will use some 200 billion kWh of electricity (that's roughly what all households in New York City combined use over five years), generating about 127 million tonnes of CO2 in the process. And that's just for desktop and laptop computers, not including peripherals or the billions of chips used in other electronic devices. Researchers are now proposing to build a fully mechanical computer based on nanoelectromechanical (NEMS) components that would use considerably less energy. Inspired by a classical mechanical computer design from 200 years ago, the main motivation behind constructing such a computer is threefold: (1) mechanical elements are more robust to electromagnetic shocks than current dynamic random access memory (DRAM) based purely on complimentary metal oxide semiconductor (CMOS) technology, (2) the power dissipated can be orders of magnitude below CMOS and (3) the operating temperature of such an NMC can be an order of magnitude above that of conventional CMOS. Today, such a mechanical computer is only a hypothetical device. However, any effort to reduce the power consumption of computers, and not increase them as happens with every new chip generation, seems like a worthwhile effort.

Jul 25th, 2007

Back in January, when the U.S. president announced his hydrogen fuel initiative and proposed to spend a total of $1.7 billion over the next five years to develop hydrogen-powered fuel cells, hydrogen infrastructure and advanced automotive technologies, he said that it will be practical and cost-effective for large numbers of Americans to choose to use clean, hydrogen fuel cell vehicles by 2020. According to the U.S. Department of Energy's (DOE) Hydrogen Program, the government's goal is to achieve "technology readiness" by around 2015 in order to allow industry to make decisions on commercialization by then. That's only eight years to go. Given where the technology is today, this goal seems very ambitious, to say the least. Nanotechnology could help speed up the journey to the hydrogen society, but it will take some sensational breakthroughs on the way. The three key areas for the vehicles (we will not touch on the infrastructure issues here) are clean - the emphasis is on clean - hydrogen production, hydrogen storage, and the fuel cell itself. We'll take a look at how nanotechnology will play a role in these areas.

Back in January, when the U.S. president announced his hydrogen fuel initiative and proposed to spend a total of $1.7 billion over the next five years to develop hydrogen-powered fuel cells, hydrogen infrastructure and advanced automotive technologies, he said that it will be practical and cost-effective for large numbers of Americans to choose to use clean, hydrogen fuel cell vehicles by 2020. According to the U.S. Department of Energy's (DOE) Hydrogen Program, the government's goal is to achieve "technology readiness" by around 2015 in order to allow industry to make decisions on commercialization by then. That's only eight years to go. Given where the technology is today, this goal seems very ambitious, to say the least. Nanotechnology could help speed up the journey to the hydrogen society, but it will take some sensational breakthroughs on the way. The three key areas for the vehicles (we will not touch on the infrastructure issues here) are clean - the emphasis is on clean - hydrogen production, hydrogen storage, and the fuel cell itself. We'll take a look at how nanotechnology will play a role in these areas.

Jul 19th, 2007

By now we all are aware of the issues concerning greenhouse gases and climate change, so there is no need to repeat them here. Rather, we will take a look at the areas where nanotechnologies could have a beneficial environmental impact - especially with regard to reducing greenhouse gases - above current technologies, and the barriers potentially preventing their adoption. A study commissioned by the nanotechnology group of the UK's Department for Environment Food and Rural Affairs (Defra) looked into the the policy implications of nanotechnologies that will benefit the environment. The report of the study, "Environmentally beneficial nanotechnologies: barriers and opportunities", investigates the opportunities and potential obstacles to adoption of a number applications of nanotechnology which could be used to cut use of non-renewable energy sources and reduce greenhouse gas emissions. Five nanotechnology applications were subject to detailed investigation: fuel additives, solar cells, the hydrogen economy, batteries and insulation.

By now we all are aware of the issues concerning greenhouse gases and climate change, so there is no need to repeat them here. Rather, we will take a look at the areas where nanotechnologies could have a beneficial environmental impact - especially with regard to reducing greenhouse gases - above current technologies, and the barriers potentially preventing their adoption. A study commissioned by the nanotechnology group of the UK's Department for Environment Food and Rural Affairs (Defra) looked into the the policy implications of nanotechnologies that will benefit the environment. The report of the study, "Environmentally beneficial nanotechnologies: barriers and opportunities", investigates the opportunities and potential obstacles to adoption of a number applications of nanotechnology which could be used to cut use of non-renewable energy sources and reduce greenhouse gas emissions. Five nanotechnology applications were subject to detailed investigation: fuel additives, solar cells, the hydrogen economy, batteries and insulation.

Jul 16th, 2007

Our modern lifestyle exposes us to hundreds of chemical substances every day, quite a number of them are known to be hazardous, if not outright toxic. The long, long list ranges from toxic chemicals and heavy metals included in electronic waste to insecticides and herbicides that find their way into the food chain, to flame retardant chemicals in buildings and furniture. A European project has set out to give an overview of already used and conceivable applications of nanotechnology in order to replace hazardous chemicals. The overall idea behind this project is to identify new nanotechnology applications which could help to reduce the risks related to hazardous substances and chemical processes. Currently, nanotechnologies are not contributing exceptionally to an increase in the substitution of hazardous substances for safer ones. However, experts believe that this could well change in the future. These are two of the messages coming out of a study by STOA, the European Parliament's Scientific Technology Options Assessment committee, on the role of nanotechnology in chemical substitution.

Our modern lifestyle exposes us to hundreds of chemical substances every day, quite a number of them are known to be hazardous, if not outright toxic. The long, long list ranges from toxic chemicals and heavy metals included in electronic waste to insecticides and herbicides that find their way into the food chain, to flame retardant chemicals in buildings and furniture. A European project has set out to give an overview of already used and conceivable applications of nanotechnology in order to replace hazardous chemicals. The overall idea behind this project is to identify new nanotechnology applications which could help to reduce the risks related to hazardous substances and chemical processes. Currently, nanotechnologies are not contributing exceptionally to an increase in the substitution of hazardous substances for safer ones. However, experts believe that this could well change in the future. These are two of the messages coming out of a study by STOA, the European Parliament's Scientific Technology Options Assessment committee, on the role of nanotechnology in chemical substitution.

Jul 12th, 2007

A lot of buzz has been created by the term "green nanotechnology". In a broad sense, this term includes a wide range of possible applications, from nanotechnology-enabled, environmentally friendly manufacturing processes that reduce waste products (ultimately leading to atomically precise molecular manufacturing with zero waste); the use of nanomaterials as catalysts for greater efficiency in current manufacturing processes by minimizing or eliminating the use of toxic materials (green chemistry principles); the use of nanomaterials and nanodevices to reduce pollution (e.g. water and air filters); and the use of nanomaterials for more efficient alternative energy production (e.g. solar and fuel cells). Unfortunately, there is a flip side to these benefits. As scientists experiment with the development of new chemical or physical methods to produce nanomaterials, the concern for a negative impact on the environment is also heightened: some of the chemical procedures involved in the synthesis of nanomaterials use toxic solvents, could potentially generate hazardous byproducts, and often involve high energy consumption (not to mention the unsolved issue of the potential toxicity of certain nanomaterials). This is leading to a growing awareness of the need to develop clean, nontoxic and environmentally friendly procedures for synthesis and assembly of nanoparticles. Scientists are now exploring the use of biological organisms to literally grow nanomaterials.

A lot of buzz has been created by the term "green nanotechnology". In a broad sense, this term includes a wide range of possible applications, from nanotechnology-enabled, environmentally friendly manufacturing processes that reduce waste products (ultimately leading to atomically precise molecular manufacturing with zero waste); the use of nanomaterials as catalysts for greater efficiency in current manufacturing processes by minimizing or eliminating the use of toxic materials (green chemistry principles); the use of nanomaterials and nanodevices to reduce pollution (e.g. water and air filters); and the use of nanomaterials for more efficient alternative energy production (e.g. solar and fuel cells). Unfortunately, there is a flip side to these benefits. As scientists experiment with the development of new chemical or physical methods to produce nanomaterials, the concern for a negative impact on the environment is also heightened: some of the chemical procedures involved in the synthesis of nanomaterials use toxic solvents, could potentially generate hazardous byproducts, and often involve high energy consumption (not to mention the unsolved issue of the potential toxicity of certain nanomaterials). This is leading to a growing awareness of the need to develop clean, nontoxic and environmentally friendly procedures for synthesis and assembly of nanoparticles. Scientists are now exploring the use of biological organisms to literally grow nanomaterials.

Jun 21st, 2007

Ethanol is all the rage these days. Although we have been drinking ethanol, an alcohol, for thousands of years (fermented beverages such as beer and wine may contain up to 15-25% ethanol by volume), the recent interest has been sparked by its use as a renewable fuel alternative to gasoline. Indeed, the largest single use of ethanol is as a motor fuel and fuel additive. Ethanol is produced by fermentation when certain species of yeast metabolize sugar. The process works with all biological feedstocks that contain appreciable amounts of sugar or materials that can be converted into sugar such as starch or cellulose. The primary feedstock for ethanol production in the U.S. is corn. In Brazil, the world's leading ethanol producer, it's mostly derived from sugar cane. While there is a heated controversy over the economic and ecological benefits of using biomass for producing ethanol fuel, it seems that nanotechnology's jack-of-all-trades, the carbon nanotube (CNT), might provide a solution here as well. CNTs are increasingly recognized as promising materials for catalysis, either as catalysts themselves, as catalyst additives or as catalyst supports. Researchers in China now have used CNTs loaded with rhodium (Rh) nanoparticles as reactors to convert a gas mixture of carbon monoxide and hydrogen into ethanol. This appears to be the first example where the activity and selectivity of a metal-catalyzed gas-phase reaction benefits significantly from proceeding inside a nanosized CNT reaction vessel.

Ethanol is all the rage these days. Although we have been drinking ethanol, an alcohol, for thousands of years (fermented beverages such as beer and wine may contain up to 15-25% ethanol by volume), the recent interest has been sparked by its use as a renewable fuel alternative to gasoline. Indeed, the largest single use of ethanol is as a motor fuel and fuel additive. Ethanol is produced by fermentation when certain species of yeast metabolize sugar. The process works with all biological feedstocks that contain appreciable amounts of sugar or materials that can be converted into sugar such as starch or cellulose. The primary feedstock for ethanol production in the U.S. is corn. In Brazil, the world's leading ethanol producer, it's mostly derived from sugar cane. While there is a heated controversy over the economic and ecological benefits of using biomass for producing ethanol fuel, it seems that nanotechnology's jack-of-all-trades, the carbon nanotube (CNT), might provide a solution here as well. CNTs are increasingly recognized as promising materials for catalysis, either as catalysts themselves, as catalyst additives or as catalyst supports. Researchers in China now have used CNTs loaded with rhodium (Rh) nanoparticles as reactors to convert a gas mixture of carbon monoxide and hydrogen into ethanol. This appears to be the first example where the activity and selectivity of a metal-catalyzed gas-phase reaction benefits significantly from proceeding inside a nanosized CNT reaction vessel.

Jun 8th, 2007

Diesel-burning engines are a major contributor to environmental pollution. They emit a mixture of gases and fine particles that contain some 40, mostly toxic chemicals, including benzene, butadiene, dioxin and mercury compounds. Diesel exhaust is listed as a known or probable human carcinogen by several state and federal agencies in the United States. Wouldn't it be nice if we could render diesel soot harmless before it gets released into the environment? Wouldn't it even be nicer if we could use this soot to manufacture something useful? Japanese scientists have come up not only with a unique technique for effectively collecting diesel soot but also a method for using this soot as a precursor for the production of single-walled carbon nanotubes. How is that as a practical example for green nanotechnology?

Diesel-burning engines are a major contributor to environmental pollution. They emit a mixture of gases and fine particles that contain some 40, mostly toxic chemicals, including benzene, butadiene, dioxin and mercury compounds. Diesel exhaust is listed as a known or probable human carcinogen by several state and federal agencies in the United States. Wouldn't it be nice if we could render diesel soot harmless before it gets released into the environment? Wouldn't it even be nicer if we could use this soot to manufacture something useful? Japanese scientists have come up not only with a unique technique for effectively collecting diesel soot but also a method for using this soot as a precursor for the production of single-walled carbon nanotubes. How is that as a practical example for green nanotechnology?

May 30th, 2007

A revolutionary new environmental biotechnology - the Microbial Fuel Cell - turns the treatment of organic wastes into a source of electricity. Fuel cell technology, despite its recent popularity as a possible solution for a fossil-fuel free future, is actually quite old. The principle of the fuel cell was discovered by German scientist Christian Friedrich Schoenbein in 1838 and published in 1839. Based on this work, the first fuel cell was developed by Welsh scientist Sir William Robert Grove in 1843. The operating principle of a fuel cell is fairly straightforward. It is an electrochemical energy conversion device that converts the chemical energy from fuel (on the anode side) and oxidant (on the cathode side) directly into electricity. Today, there are many competing types of fuel cells, depending on what kind of fuel and oxidant they use. Many combinations of fuel and oxidant are possible. For instance, hydrogen cell uses hydrogen as fuel and oxygen as oxidant. Other fuels include hydrocarbons and alcohols. An interesting - but not commercially viable yet - variant of the fuel cell is the microbial fuel cell (MFC) where bacteria oxidize compounds such as glucose, acetate or wastewater. Researchers in Spain have fabricated multi-walled carbon nanotube (MWCNT) scaffolds with a micro-channel structure in which bacteria can grow. This scaffold structure could be used as electrodes in microbial fuel cells.

A revolutionary new environmental biotechnology - the Microbial Fuel Cell - turns the treatment of organic wastes into a source of electricity. Fuel cell technology, despite its recent popularity as a possible solution for a fossil-fuel free future, is actually quite old. The principle of the fuel cell was discovered by German scientist Christian Friedrich Schoenbein in 1838 and published in 1839. Based on this work, the first fuel cell was developed by Welsh scientist Sir William Robert Grove in 1843. The operating principle of a fuel cell is fairly straightforward. It is an electrochemical energy conversion device that converts the chemical energy from fuel (on the anode side) and oxidant (on the cathode side) directly into electricity. Today, there are many competing types of fuel cells, depending on what kind of fuel and oxidant they use. Many combinations of fuel and oxidant are possible. For instance, hydrogen cell uses hydrogen as fuel and oxygen as oxidant. Other fuels include hydrocarbons and alcohols. An interesting - but not commercially viable yet - variant of the fuel cell is the microbial fuel cell (MFC) where bacteria oxidize compounds such as glucose, acetate or wastewater. Researchers in Spain have fabricated multi-walled carbon nanotube (MWCNT) scaffolds with a micro-channel structure in which bacteria can grow. This scaffold structure could be used as electrodes in microbial fuel cells.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed