| Posted: Nov 23, 2017 | |

Designing lubricant-infused surfaces with the help of predictive models |

|

| (Nanowerk Spotlight) Liquid-impregnated coating technologies such as LiquiGlide, developed in 2009 by MIT’s Kripa Varanasi and David Smith, or SLIPS (Slippery Liquid-Infused Porous Surfaces), developed in 2011 by Joanna Aizenberg's lab at Wyss Institute, involve nanoscale texturing of a surface, which is then coated with a – usually lubricating – liquid. | |

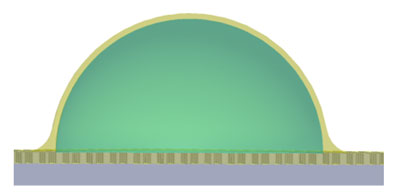

| A lubricant infused surface is comprised of a textured solid surface into which a lubricating fluid is spontaneously wicked. | |

| "Lubricant infused surfaces can exhibit excellent fluid repellency if designed properly; however, in past work, the design of lubricant infused surfaces was based on empirical measurement of the interactions between different fluids and solids," says Daniel Preston, at the time of this work a PhD researcher in Evelyn Wang's Device Research Laboratory at MIT, now a Postdoctoral Fellow at the Whitesides Research Group at Harvard. "We developed a model to determine which lubricant infused surfaces will work and which will fail based on material properties." | |

|

|

| A lubricant infused surface is comprised of a textured solid surface (gray) into which a lubricating fluid (yellow) is spontaneously wicked. Lubricant infused surfaces are capable of repelling low surface tension impinging fluids (blue). (Image: Daniel Preston) | |

| Previous work relied on either low-surface-energy materials, which often have poor electrical and thermal conductivity limiting applications in heat transfer and lab-on-a-chip, or low-surface-energy coatings, which are typically not robust enough for extended industrial use. | |

| Insight gained from this model revealed that the textured solid surface does not need to be made from or coated with a low-surface-energy material; based on this insight, the MIT team demonstrated a lubricant infused surface built on a high-surface-energy, uncoated textured solid, thereby eliminating the need for the low-surface-energy coatings prevalent in prior work. | |

| "This is exciting because low-surface-energy coatings are plagued by a lack of robustness, and our proposed method using uncoated solids and avoiding these coatings will allow application in harsh environments or over long durations," Preston tells Nanowerk. | |

| In a paper in ACS Applied Materials & Interfaces ("Design of Lubricant Infused Surfaces"), first-authored by Preston, Wang's group developed a lubricant infused surface built on an uncoated textured solid, eliminating the need for fragile low-surface-energy coatings and also allowing repulsion of the lowest surface tension impinging fluid demonstrated to date. | |

| "This work has implications in areas of fundamental research where droplet repellency is advantageous, including biology, lab-on-a-chip, fluid dynamics, and phase-change heat transfer," notes Preston. "We envision early commercial adoption of this technology in the refrigeration and hydrocarbon processing industries, where repulsion of fluids with very low surface tensions is critical." | |

|

|

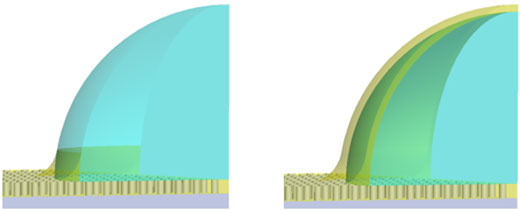

| A droplet is repelled from a lubricant infused surface, shown as a model quarter-droplet here. The ideal lubricant infused surface design results in a highly mobile droplet (left), but a droplet can also become cloaked with a thin layer of lubricant (right) or completely fail by spreading over the surface or displacing the lubricant. (Image: Daniel Preston) | |

| Startups focusing on lubricant infused surfaces, including LiquiGlide and SLIPS Technologies, may also find this discovery useful in eliminating the need for low-surface-energy textured solids from their products. | |

| The MIT team was motivated to explore this work by insight gained from their detailed surface-energy-based modeling of lubricant infused surfaces, which indicated that their experimental findings were possible. | |

| Lubricant depletion from the surface is the biggest hurdle to commercial application. The lubricant can be depleted by evaporation, carried away by repelled droplets either due to solubility in the repelled droplets or cloaking of the repelled droplets with a thin layer of lubricant, or even sheared off by repelled droplets sliding across the surface. | |

| Going forward, they will explore lubricants with lower vapor pressures, which will be necessary for eventual use in open systems where the lubricant can evaporate over time. They will also investigate the effects of varying temperature and pressure on their findings. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|