| Jul 09, 2021 | |

Cooling high power electronics - boron arsenide spreads heat better than diamond |

|

| (Nanowerk Spotlight) Scientists at UCLA have integrated new super thermal conductors – boron arsenide and boron phosphide that they developed recently – as a thermal substrate for power electronics devices such as gallium nitride (GaN) high electron-mobility transistors (HEMTs). The study demonstrates high cooling performance better than the best state-of-the-art technologies. | |

| This work is reported in a paper published in Nature Electronics ("Integration of boron arsenide cooling substrates into gallium nitride transistors") | |

| Some relevant studies are recently published in Nature Communications, Science, Physical Review B, and Nano Letters. | |

|

|

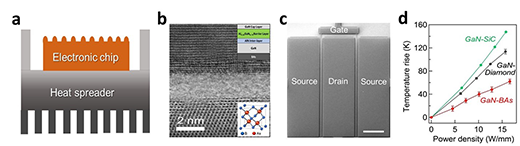

| Figure 1: Scientists integrate a new semiconductor, boron arsenide (BAs) with wide bandgap electronics to achieve benchmark high performance for thermal management. (a) Schematic illustrating thermal management in electronics chip packaging. (b) Heterogeneous interface of BAs-GaN examined by transmission electron microscopy with atomic resolution. Insets, crystal structure of BAs (bottom) and epitaxial layers of HEMTs. (c) Scanning electron microscopy image of fabricated AlGaN/GaN HEMT devices on BAs cooling substrate. (d) Demonstrated record-high thermal management performance of GaN-BAs devices beyond state-of-the-art cooling technologies including GaN-SiC and GaN-diamond, through in-situ measurement of hot spot temperature rise in operating HEMTs as a function of transistor power density. (Image courtesy of the researchers) (click on image to enlarge) | |

| Heat dissipation has increasingly become a bottleneck for modern electronics. In particular, the development of wide bandgap semiconductor devices has led to many advancements of high power and high frequency electronics. However, the performance and reliability of these systems relies on the ability to efficiently dissipate thermal energy from the devices during operation. | |

| To keep computer processors cool, materials that can draw heat away and dissipate it are incorporated into their design – as “heat spreaders” – a heat sink that also sends heat out. Although, currently diamond and silicon carbide have been used as heat spreaders in such devices, an intrinsic large thermal resistance has usually been found at interfaces within these device architectures and limits the effectiveness of such solutions. | |

| The UCLA team showed that transistors incorporating boron arsenide (BAs) or boron phosphide (BP) – the two excellent heat conducting materials they recently developed -- into the design of chip as a heat spreader exceeds the thermal management performance of the best state of the art. | |

| In experiments running wide bandgap GaN high electron mobility transistors (HEMTs) at near-capacity, they saw their chips with boron arsenide heat sinks see a temperature increase in on-chip hot-spot temperatures of 60 degrees Celsius. This is significantly lower than industrial standard chips, and the research prototype chips using diamond (110 degree) or silicon carbide (140 degree) as their heat sink. | |

| The study attributes the high thermal performance of BAs and BP to a combination of high thermal conductivity and low thermal boundary resistance (TBR), relative to the other materials. The thermal boundary conductance (reciprocal of TBR) of GaN/BAs is at least ∼250MW/m-2 K-1 and about eight times higher than that the state of the art of GaN/diamond. | |

| The study shows that the lower TBR of GaN/BAs over GaN/diamond is attributed to a better overlap between the properties of the quantized lattice vibrations (phonons) in GaN/BAs. At a simple level, the Debye temperature, derived from the linear spectrum model for specific heat at low temperature, for BAs is much closer to that of GaN (and other common electronic materials) than diamond. | |

| The paper also reports more advanced theoretical work down to the atomic level, showing consistence with experiments. These results clearly show that boron arsenide devices can sustain much higher operation power than the state of the art, and under conditions when most current technologies would fail. | |

| The research study demonstrated how to process the materials heterostructures and integrate into a HEMTs chip design. The successful demonstration suggests that a next step would be adoption by industry for electronics packaging and incorporated into integrated circuits. | |

| “Along with many others in the field, we have been devoted to this effort for last several years.” said Yongjie Hu, a professor at UCLA who led the research, “My group have made progress from materials development, transport characterizations, modeling analysis, and now we are very excited to see the demonstrated device integration of these building blocks to make transformative technology.” | |

| In a separate work ("Flexible thermal interface based on self-assembled boron arsenide for high-performance thermal management"), the UCLA team also made innovation in self-assembled manufacturing of these materials and developed high-performance flexible thermal interfaces for wearable electronics and soft robotics. | |

| Source: Provided by University of California, Los Angeles | |

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|